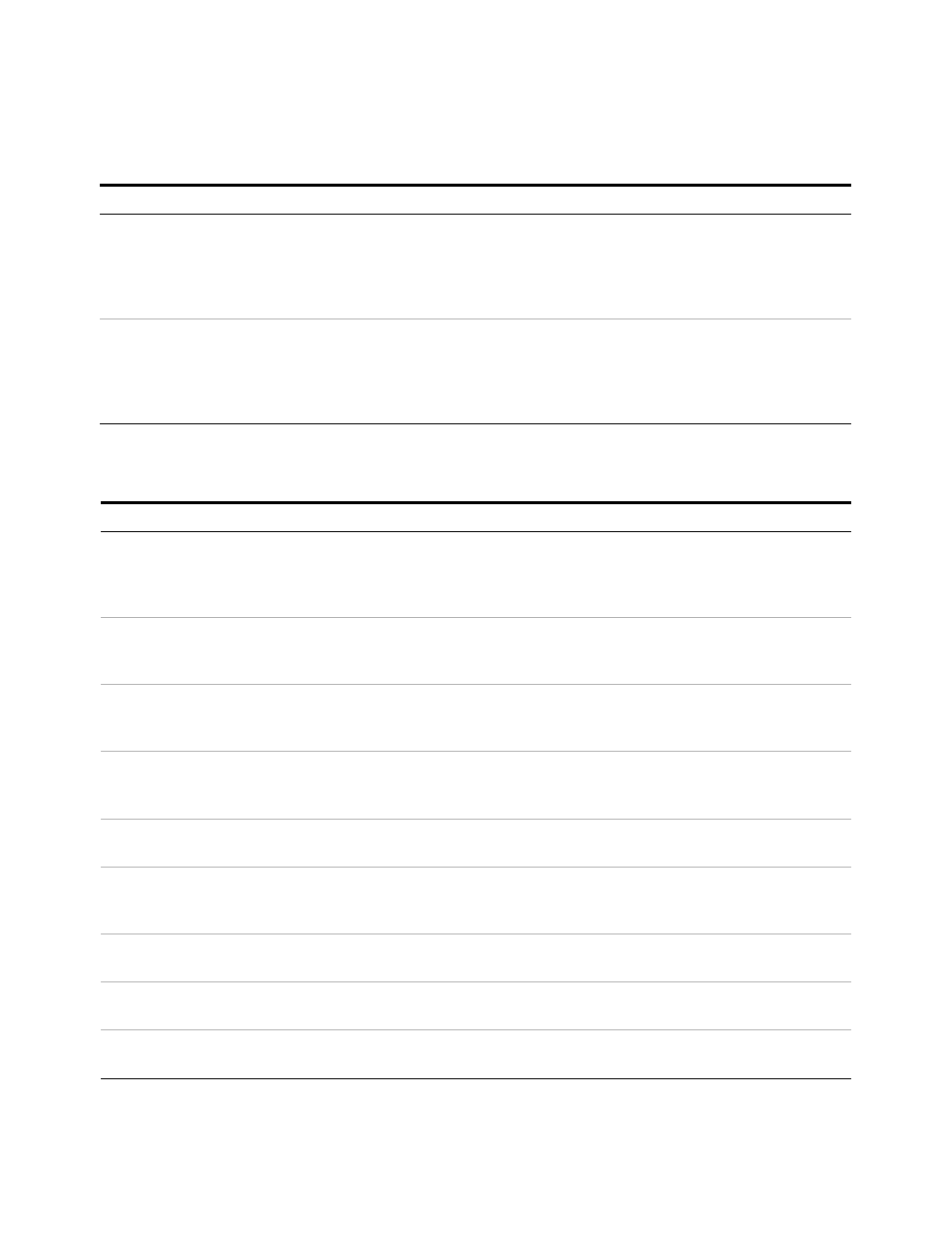

Table 6. troubleshooting pump issues – Agilent Technologies G6600-90006 User Manual

Page 115

Operation and Maintenance Manual

115

Burner Fault Cycles. (off and

ON)

Cracked tube.

Pressure increases

>525 torr, Burner faults.

Cycle repeated as

temperature and pressure

reset.

Replace broken tubes.

Burner Fault Cycles (off and

ON)

Leak in Burner.

Pressure increases

>600 torr, Burner faults.

Cycle repeated as

temperature and pressure

reset.

Locate and repair leaks,

check integrity of ferrules.

Table 5 Troubleshooting Detector Issues (continued)

Problem

Possible Cause

Diagnosis

Corrective Action

Table 6 Troubleshooting Pump Issues

Problem

Possible Cause

Diagnosis

Corrective Action

Pump is noisy

High-pressure dry piston.

Pressure in the reaction cell

is unacceptably high and the

pump is getting audibly

noisy.

Change sleeve/seal.

Pump Doesn’t Start

Dry piston seals have

recently been changed.

Pump fuses blow

immediately after changing

the seals and sleeves.

Dry piston requires break-in

time of a few minutes after

seals are changed.

Pump Doesn't Start

Pump switch off (dry piston

pump must start from

atmospheric pressure).

Locate pump switch on

pump and verify position.

Turn ON switch.

Fuses Blow on Startup

Emulsified oil (worn seals

and head on dry piston

pump).

Inspect oil for integrity.

Change pump oil, and plug

unit into wall to run for 10-15

minutes.

Water in Pump

Cracked coalescing filter.

Milky yellow oil in the pump

window.

Change coalescing filter and

pump oil.

Reaction Cell Pressure High

chemical trap clogged.

Remove trap from the

vacuum line and confirm

expected pressure readings.

Change chemical trap.

Reaction Cell Pressure High

Leak in ozone generator.

Air regulator falls rapidly to

zero when turned off.

Replace ozone generator.

Pump Loses Oil

Gurgle Sound

Ballast Open.

Oil level drops.

Reset ballast

See Pump specific sections.

High level of oil in

Coalescing Filter

Plugged oil return restrictor

No visible movement of oil in

the return line.

Change filter and clear

restrictor.