Traceability, Weldscore, Production monitoring™ architecture – Lincoln Electric IM8001 PRODUCTION MONITORING 2.2 User Manual

Page 121: Feed

Appendix A. Additional Information

Archive of Data from the Database

A.4

Production Monitoring™ User Manual

IM8001

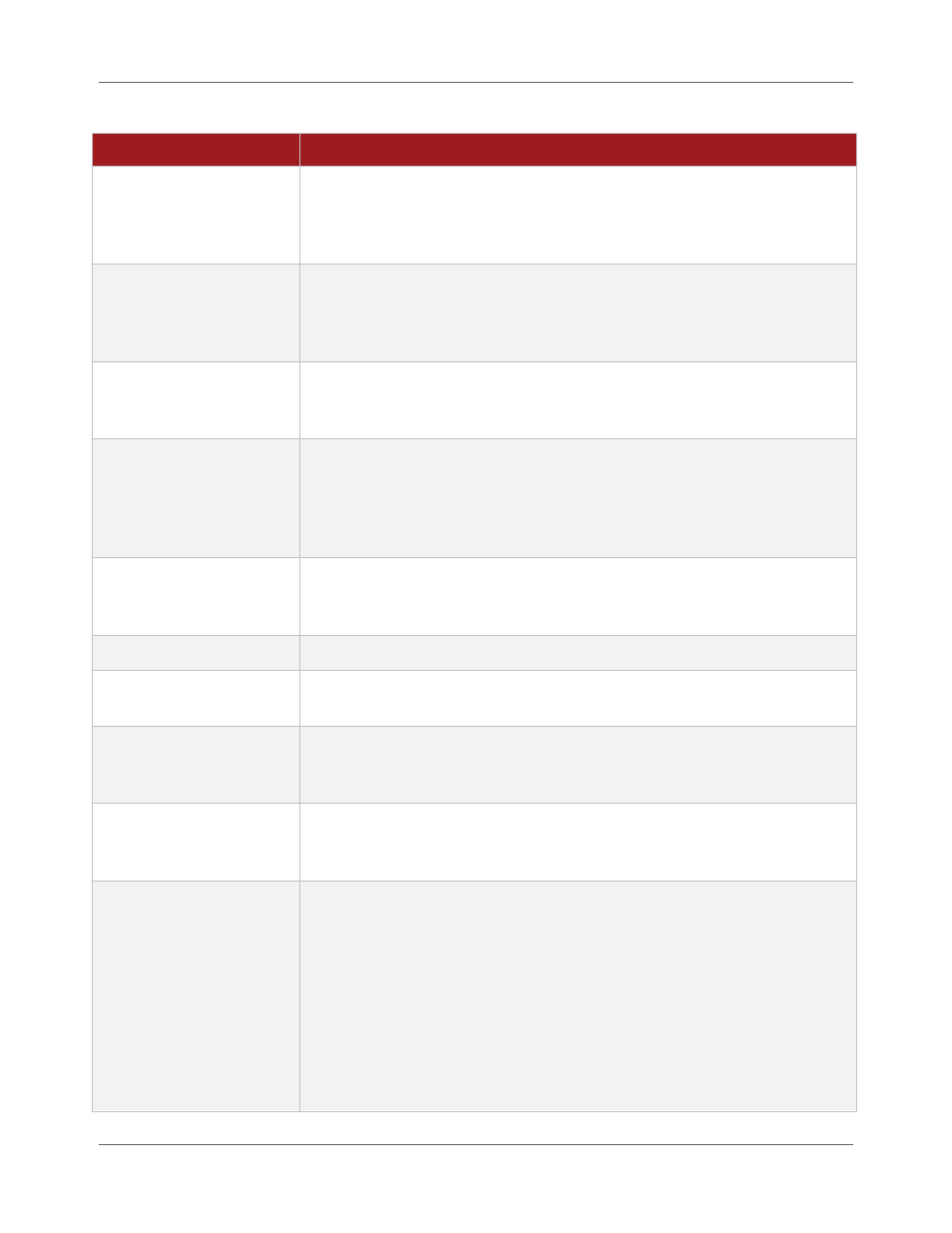

Table 5.1

Columns in the Weld Archive File

Column Heading

Description

ID

This is the database record number for the weld. When a Welding Power

Source sends weld records to the Production Monitoring™ database, the

database assigns an identification number to each weld. This column

represents that number, also known as the Weld ID in the main application.

WelderName

This column displays the name of the Welding Power Source used to make

this weld. This is the name of the power source at the time the weld was

made. It was entered by the Production Monitoring™ administrator when

adding the power source to the Asset Tree.

Model

This is the model of the Welding Power Source that made this weld. The

model information comes from the TOK file uploaded when adding the

Welding Power Source to the Asset Tree.

ProfileNumber

This column displays the number of the Weld Profile used at the time of the

weld. If a Weld Operator did not choose a Weld Profile for the weld, the

Welding Power Source automatically selected the last profile. For those

power sources utilizing 32 profiles, this is Profile 32. For those utilizing 200

profiles, the weld is assigned to Profile 200.

MachineCounter

When a Welding Power Source creates a weld, it assigns an identification

number to that weld for debugging purposes. The MachineCounter column

represents that number.

SerialNumber

The SerialNumber is the number that was assigned to this weld.

StartDateTime

The StartDateTime column displays the date and specific time the Welding

Power Source began performing the weld.

Duration

The Duration column displays the time it took to make the weld. This is the

length of time (in seconds) from the time listed in the StartDateTime column

to the time the Welding Power Source stopped welding.

EndDateTime

The EndDateTime column is a calculated value. The system added the

Duration column to the StartDateTime column to calculate the date and time

the Welding Power Source stopped welding.

Status

If any limit errors occurred during the weld, the Status column displays the

code of the error. If no error occurred during the weld, the value in this

column is 0. The following codes could appear in the Status column:

0x8000 Fault

Latch

0x4000 Fault

0x2000 Alarm

Latch

0x1000 Alarm

0x0800 Unused

Bit

0x0400 Unused

Bit