Lincoln Electric IM8001 PRODUCTION MONITORING 2.2 User Manual

Page 110

Traceability Tab

Chapter 5. Using Production Monitoring™

IM8001

Production Monitoring™ User Manual

5.37

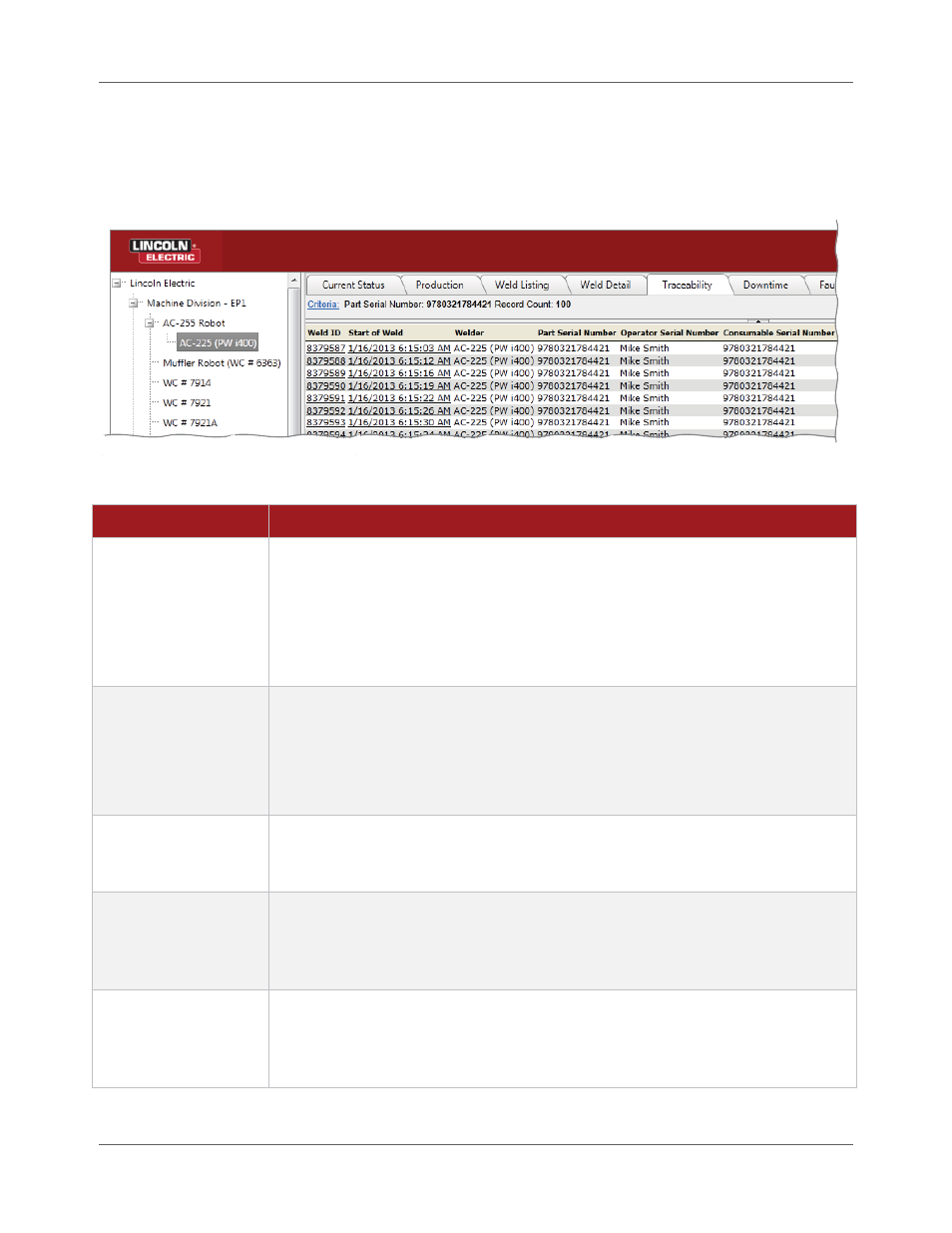

Traceability Report

The Traceability report lists all the welds that went into making a specific part, based on several bits of

information. Table 5.21 explains the columns on the report in more detail. See page 5.36 for details on the

criteria available for the report.

Figure 5.30 Traceability Report

Table 5.21

Columns on the Traceability Report

Field

Description

Weld ID

When a Welding Power Source creates a weld, it assigns an identification number

to that weld and sends it to Production Monitoring™. The Weld ID is that

number.

If you want to see additional information about that individual weld, simply click

the underlined Weld ID. The system automatically generates a Weld Detail report

for that weld (page 5.30).

Start of Weld

The Start of Weld column displays the date and specific time the Welding Power

Source began performing the weld.

If you want to see additional information about the individual weld, simply click

the underlined date and time. The system automatically generates a Weld Detail

report for that weld (page 5.30).

Welder

This column displays the name of the Welding Power Source used to make the

weld. The Production Monitoring™ administrator entered this text when creating

the Asset Tree (page 4.2).

Part Serial Number

The Part Serial Number is the number assigned to this weld. The part number

comes from a variety of sources, depending if a person enters the number in

the Power Wave® Manager manually or if the information is transmitted

automatically.

Operator Serial

Number

This is the operator’s ID number. When an operator begins welding on a Welding

Power Source, his or her ID or badge number is entered through Power Wave®

Manager or another method. Production Monitoring™ collects the ID that is

active at the time of the weld and displays the ID in this column.