Warner Electric SFC-120, SFC-170, SFC-250, SFC-400 Bearing Mounted, Flange Mounted User Manual

Page 7

7

Warner Electric • 800-825-9050

P-200

• 819-0481

Clutch-Coupling SFC-120, SFC-170,

SFC-250, SFC-400

Installation Instructions

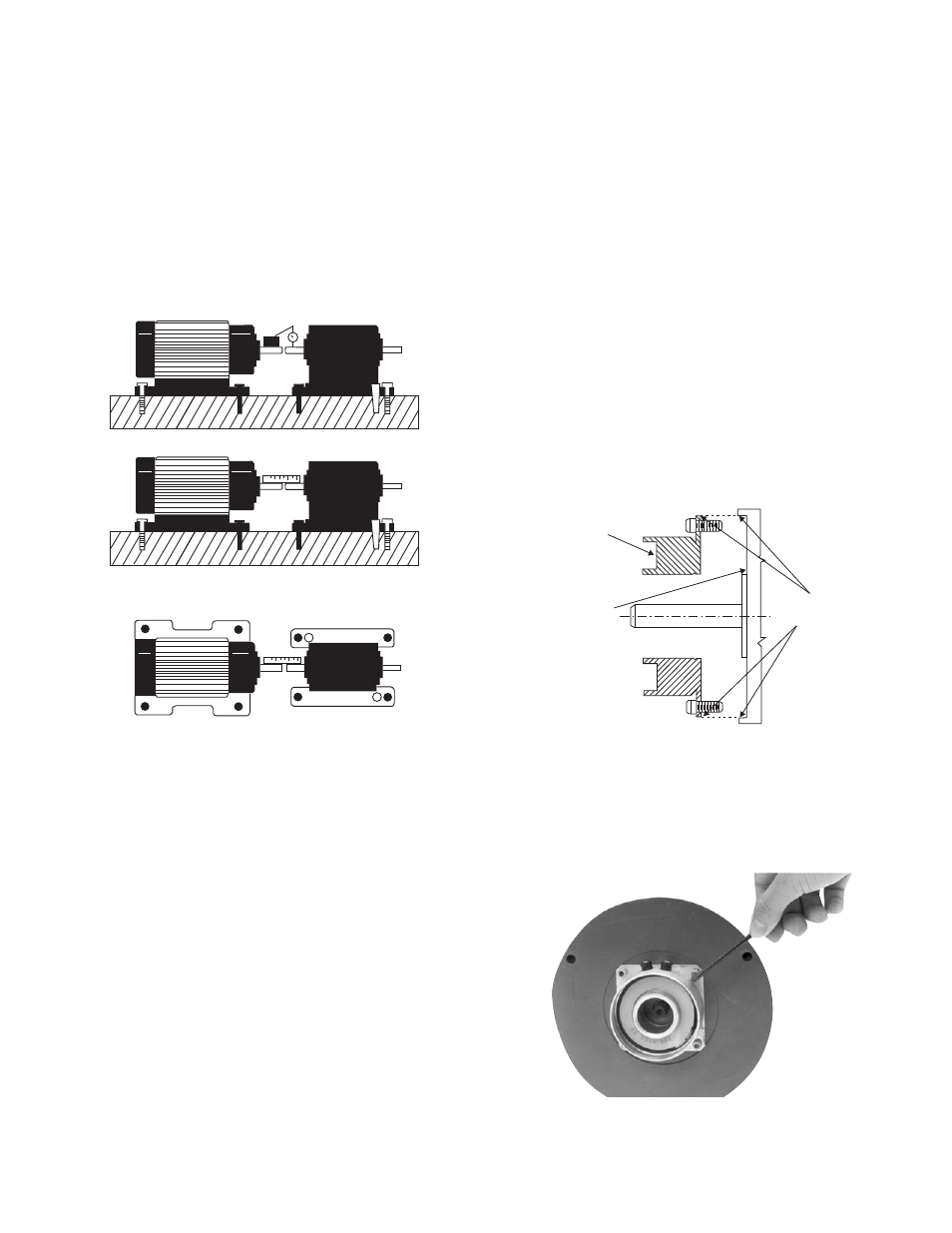

A. Aligning the Shafts

In order for the clutch-coupling unit to operate

properly, the mounting shafts of the motor and

reducer or other hardware must be aligned with

respect to each other before the unit is installed.

The two shafts should be concentric with each

other within .004 T.I.R., and angular alignment

should be within 1/2 degree.

1. Use a straight-edge to check if the shafts are

aligned with each other. For a more precise

indication of alignment, use a dial indicator.

(Figure 10)

2. Adjust the position of the motor, reducer, or

other hardware as required to achieve the

correct alignment.

3. To be sure the shafts stay in alignment, drill

holes for tapered dowel pins through the

mounting bases of the motor, reducer, or other

hardware and into the mounting surfaces. This

procedure will ensure that, after the clutch-

coupling has been installed, the shafts can

easily be placed in proper alignment again by

lining up the holes and secured by inserting the

dowel pins.

B. Installing the Conduit Box

To install the conduit box on the size 400 units, refer

to the instructions supplied with conduit box.

C. Mounting the Field-and-Rotor Assembly

Flange-Mounted Units

The fields and rotors are shipped separately for

flange-mounted units. On some applications it will

be necessary to mount the rotor first, and then

bring the field into position. In other instances the

field will be mounted first, and then the rotor

(mounted on a shaft) will be inserted into place.

1. Care must be taken in selecting the location for

mounting the field assembly. Pilot diameters are

machined on the field mounting flange to aid in

holding the field in the proper position. (Figure

1)

2. An appropriate pilot diameter must be provided

on the mounting surface as well.

3. The field assembly is then fastened in place

with capscrews and lockwashers. (Figure 2)

Field

Mounting

Surface

Pilot

Diameters

Figure 1

Figure 2