Warner Electric SFC-120, SFC-170, SFC-250, SFC-400 Bearing Mounted, Flange Mounted User Manual

Page 4

4

Warner Electric • 800-825-9050

P-200

• 819-0481

Clutch SF-120, SF-170, SF-250, SF-400

Installation Instructions

A. Installing the Conduit Box

To install the conduit box on the size 400 units, refer

to the instructions supplied with conduit box.

B. Mounting the Field-and-Rotor Assembly

Flange-Mounted Units

The fields and rotors are shipped separately for

flange-mounted units. On some applications it may

be necessary to mount the rotor first, and then bring

the field into position. In other instances the field

may be mounted first, and then the rotor (mounted

on a shaft) will be inserted into place.

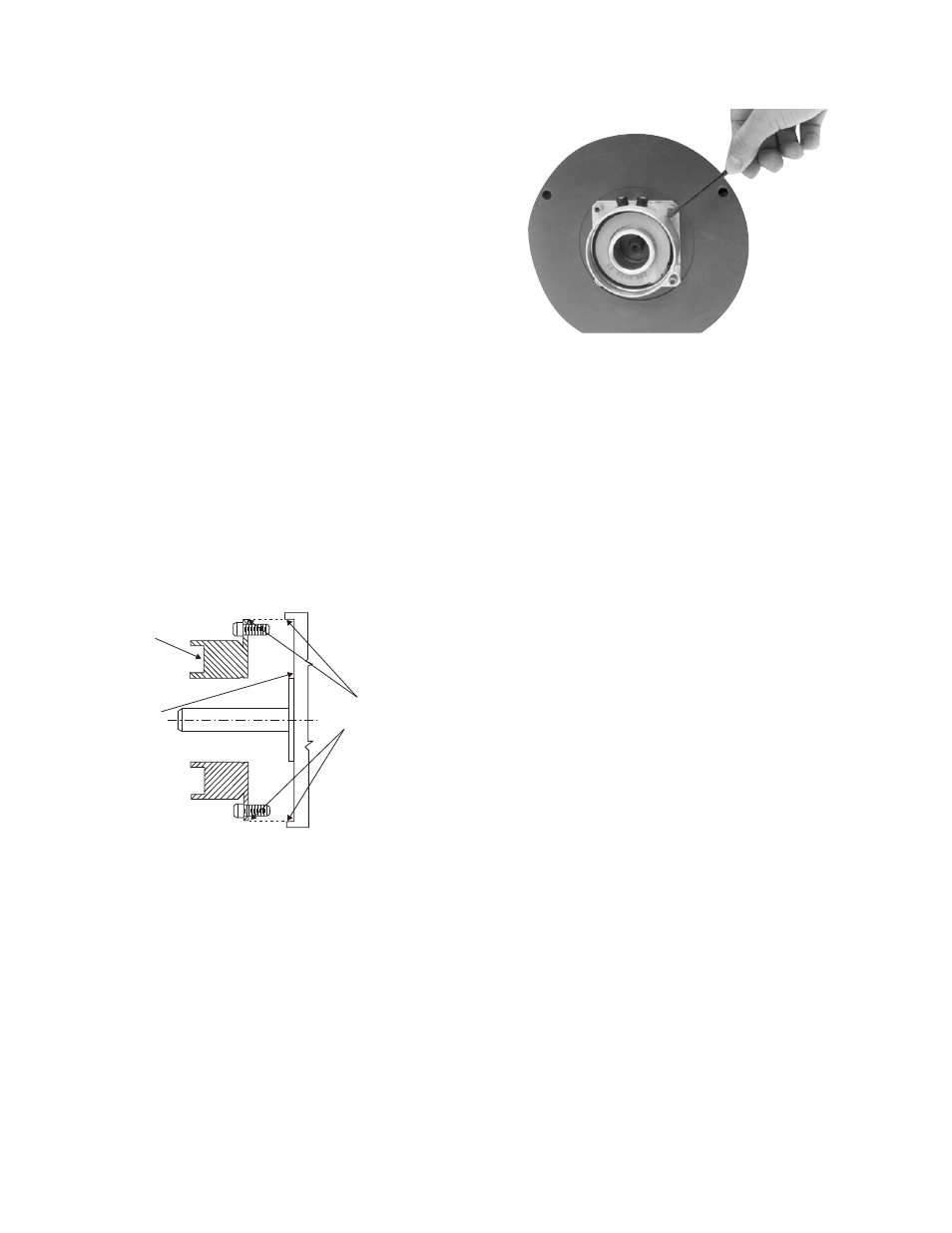

1. Care must be taken in selecting the location for

mounting the field assembly. Pilot diameters are

machined on the field mounting flange to aid in

holding the field in the proper position.

2. An appropriate pilot diameter must be provided

on the mounting surface as well. (Figure 1)

3. The field assembly is then fastened in place with

capscrews and lockwashers. (Figure 2)

4. After the unit is in place, the mounting face and

pilot must be square and concentric with the

shaft in accordance with the tolerances listed on

the drawings.

5. Insert a key into the shaft keyway.

6. Slide the rotor assembly onto the shaft over

the key.

7. Secure the assembly in this position by

alternately tightening the two setscrews.

8. Position the field and rotor in accordance with

the overall axial dimension shown on the

illustration drawings for correct size unit. Holding

this dimension will assure the proper clearance

between the field and rotor.

Bearing-Mounted Units

In bearing-mounted units, the field and rotor are

shipped as an assembly. Either this assembly or the

armature and hub assembly can be mounted on the

shaft first, depending on the characteristics on each

application.

1. Insert the key into the shaft keyway.

2. Slide the rotor assembly over the key and on to

the shaft.

3. Secure the field-and-rotor assembly in place by

alternately tightening the two set screws.

Note: The field-and-rotor assemblies for 120

units and 250 units, 1/2 inch bore,

are held in place by set screws

inserted into a set collar on the end of

the rotor hub extension. Secure these

assemblies in place by alternately

tightening the screws.

4. A tab or torque arm on the field is used to

prevent rotation of the field caused by normal

bearing drag. Insert either a pin in the U-slot or

a fork around the torque arm to prevent this

rotation. Under no circumstances, however,

should the field be so tightly restrained as to

preload the bearing.

Field

Mounting

Surface

Pilot

Diameters

Figure 1

Figure 2