2 tools, Warning caution 5.2 tools – IAI America IX-NNN8040 User Manual

Page 32

24

5. Precautions for Use

Warning

Caution

5.2 Tools

The tool mounting part must have sufficient strength and rigidity, along with adequate fastening power to

prevent positional shift.

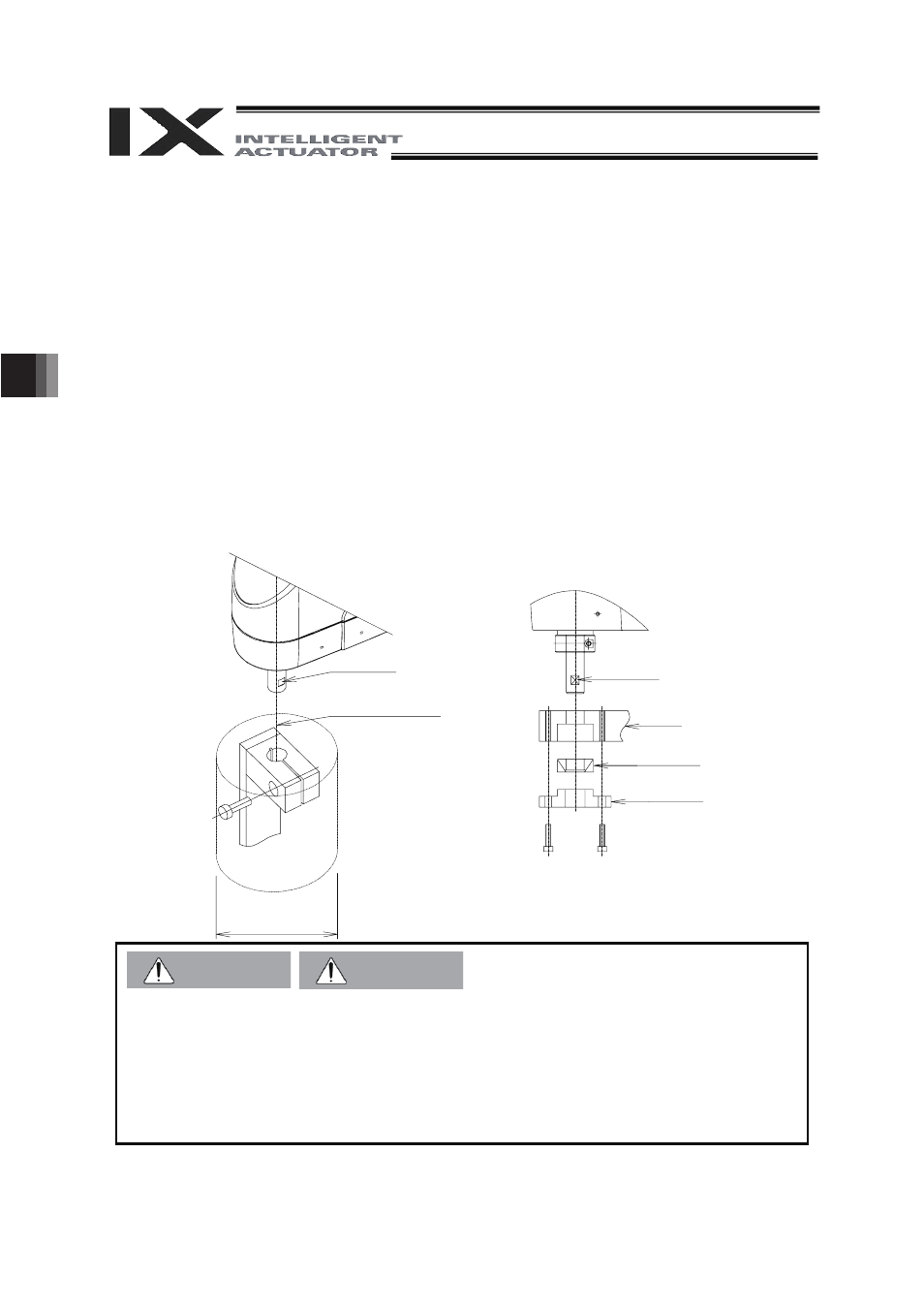

It is recommended that a tool be installed over a split ring, span ring or other appropriate part. A sample

configuration of tool installation is given below.

The diameter of each tool must not exceed 100 mm. A tool larger than this dimension will interfere with the

robot within the robot’s range of movement.

If the tool diameter exceeds 100 mm or the tool contacts any peripheral equipment, decrease the soft limits

to reduce the operation range.

Also keep the inertial moments of the tool and load within the allowable values. (Refer to 5.3, “Carrying

Load.”)

Adjust the position (direction) of axis 4 (rotational axis) using the D-cut surface at the tip of axis 4.

If the position in rotating direction is to be determined using the D-cut surface with a setscrew, use a

setscrew with resin/brass pad or screw in a setting piece made of soft material.

(Avoid affixing the tool by bolting it on the D-cut surface. It will damage the D-cut positioning surface.)

z Turn off the power to the controller and robot before installing a tool.

z If the tool mounting part does not have sufficient strength, it may break while the robot is operating

and cause the tool to detach and fly off.

z If the tool diameter exceeds 100 mm, the tool will contact the robot within its range of movement

and cause damage to the tool, work and/or robot.

z Avoid attachment of the tool at the D-cut surface via thread fastening. Doing so may damage the

D-cut positioning surface.

D-cut surface

Center of axis 4

(rotational axis)

Tool diameter

I 100 or less

D-cut surface

Tool

Span ring, etc.

Pressure flange