Maintenance inspection, 1 inspection items and inspection schedule, 2 visual inspection – IAI America RCP4W User Manual

Page 47: 3 cleaning

4. Maintenance Inspection

41

4. Maintenance Inspection

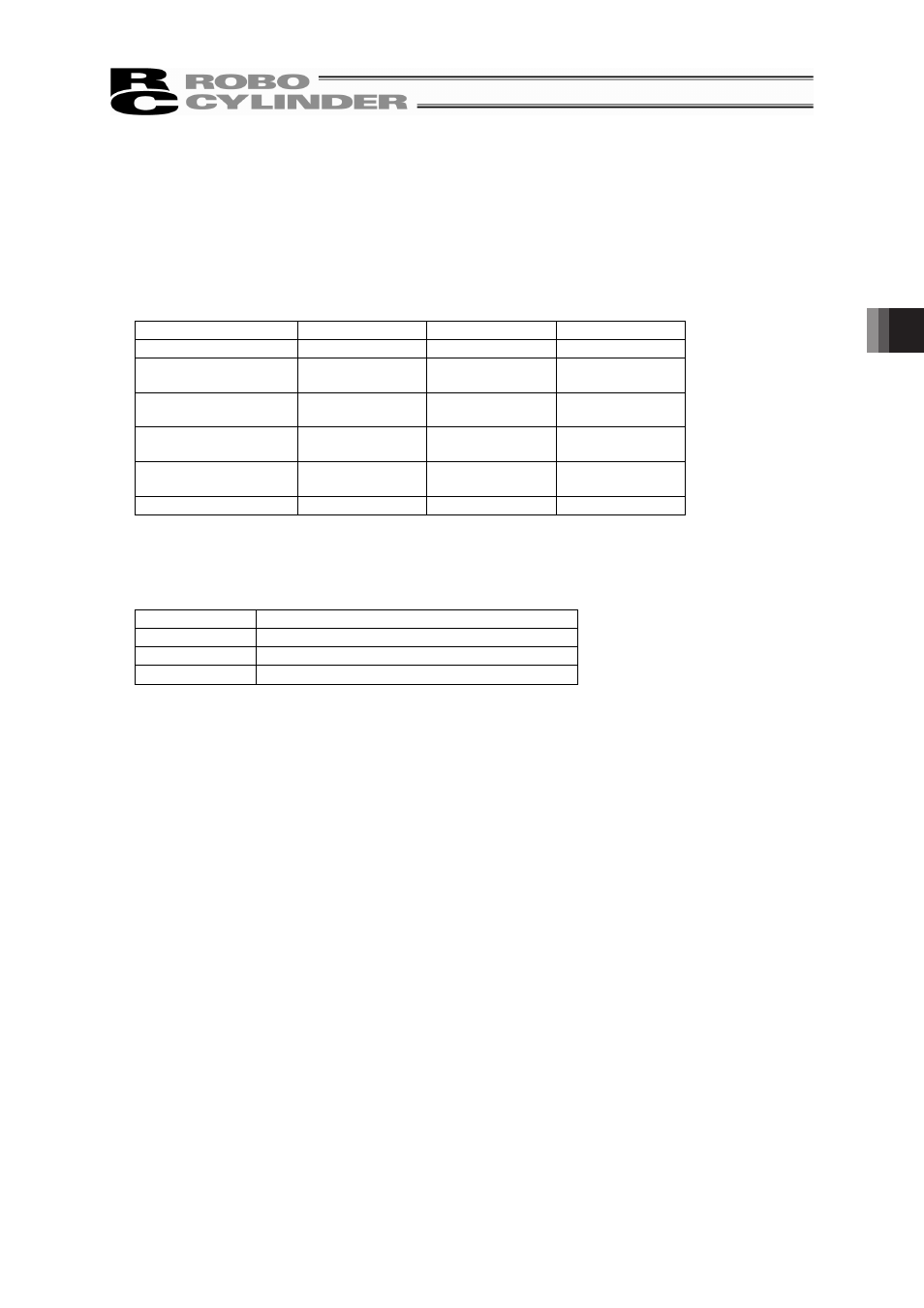

4.1 Inspection Items and Inspection Schedule

Have maintenance inspections following the intervals below.

The calculation is conducted under the condition that there are 8 working hours per day. Have

inspections more frequently if the operation frequency is high for night and day continuous operation,

etc.

䎃

Visual inspection

Internal Check

Grease supply

At startup inspection

{

1 month after start of

operation

{

{

6 months after start of

operation

{

{

1 year after start of

operation

{

{

{

Every 6 months

thereafter

{

Every 1 year since

{

{

{

䎃

4.2 Visual inspection

For the visual inspection, check the appearance following items.

䎃

Main Body

Looseness of attachment screws

Cables

Scratches, proper connection of connectors

Seal

Deformation on sealing, gap on moving slider part

Overall

Noise, vibration

* Replace the scraper (seal) in appropriate interval period as it is a maintenance part.

The reference for replacement is 3000km of operation distance or 1.5 years of used period. (The

distance and period may change depending on the condition of use such as temperature.)

4.3 Cleaning

• Please clean the external body on a regular basis.

• When cleaning, wipe with a soft cloth to remove dust and dirt.

• There is a risk of dust getting in from a clearance. Do not blow compressed air strongly to the body.

• Do not apply petroleum solvent since it may damage the resin or painted surfaces.

• When extremely dirty, wipe it off firmly with cloth that a neutral detergent or alcohol is applied on.