IAI America RCP4W User Manual

Page 46

3. Connection to the Controller

40

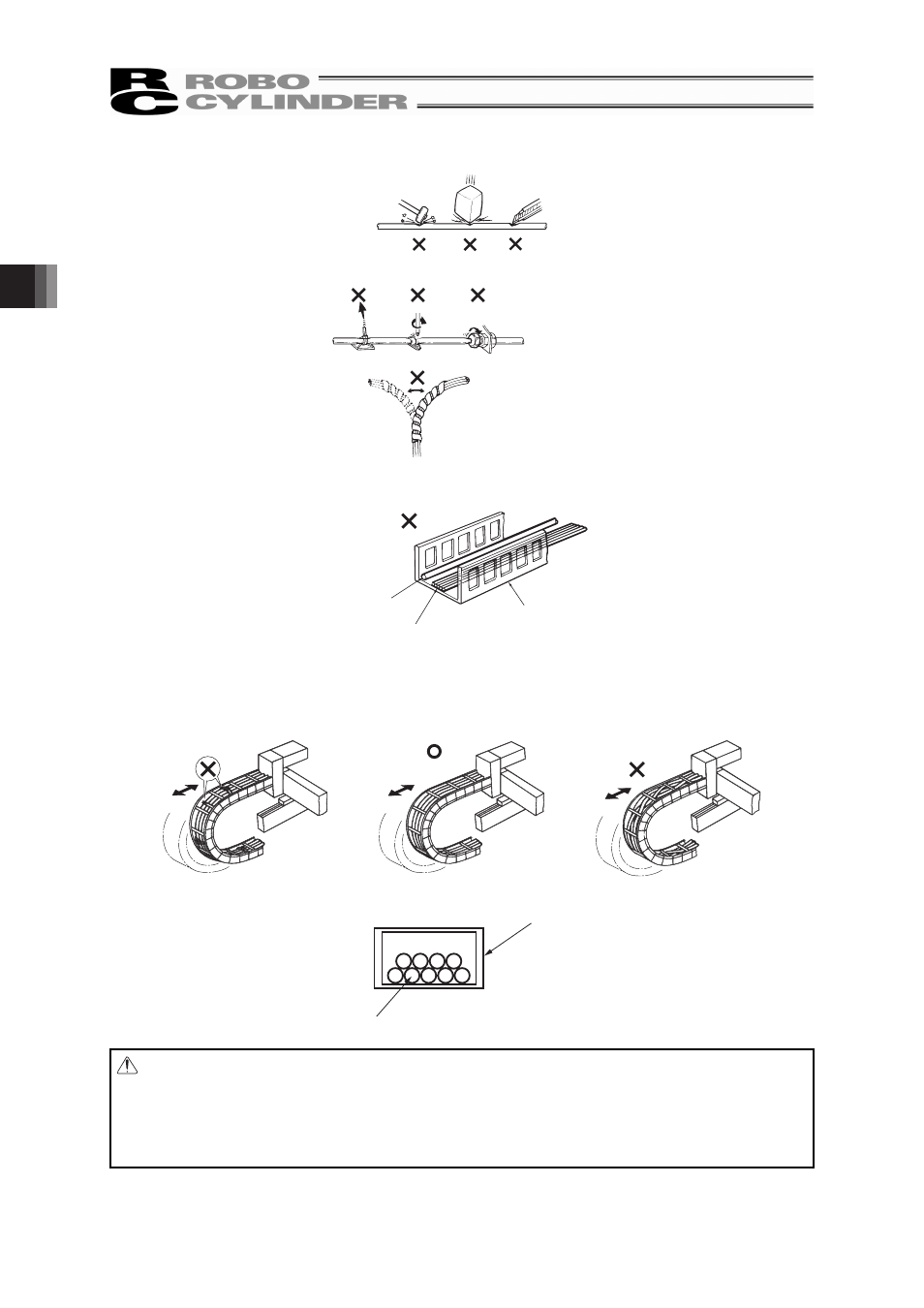

• Do not pinch, drop a heavy object onto or cut the cable.

• When fixing the cable, provide a moderate slack and do not tension it too tight.

Do not use spiral tube in any

position where cables are bent

frequently.

• Separate the I/O line, communication line and power line from each other.

Arrange so that such lines are independently routed in the duct.

Power Line

Duct

I/O Line

(Flat Cable, etc.)

• If using a cable track, make sure to use robot cables so the cables do not get twisted or entangled

inside the cable track or flexible tube, and also make the cables free to avoid the cables getting tied.

(Make sure the cables do not get pulled when being bent.)

[For the bending radius, refer to 1.4 Motor • Encoder Cables]

• The occupied volume rate for the cables, etc., inside the cable track should be 60% or less.

Cable

Cable Track

Warning:

• When the cable is connected or disconnected, make sure to turn off the power to the controller.

When the cable is connected or disconnected with the controller power turned ON, it might cause a

malfunction of the actuator and result in a serious injury or damage to the machinery.

• When the connector connection is not correct, it would be dangerous because of a malfunction of

the actuator. Make sure to confirm that the connector is connected correctly.