Ransburg, Electrode assembly resistance reading, Electrode tip inspection – Ransburg RMA Indirect A11600 User Manual

Page 71: Rma-303 indirect charge - maintenance

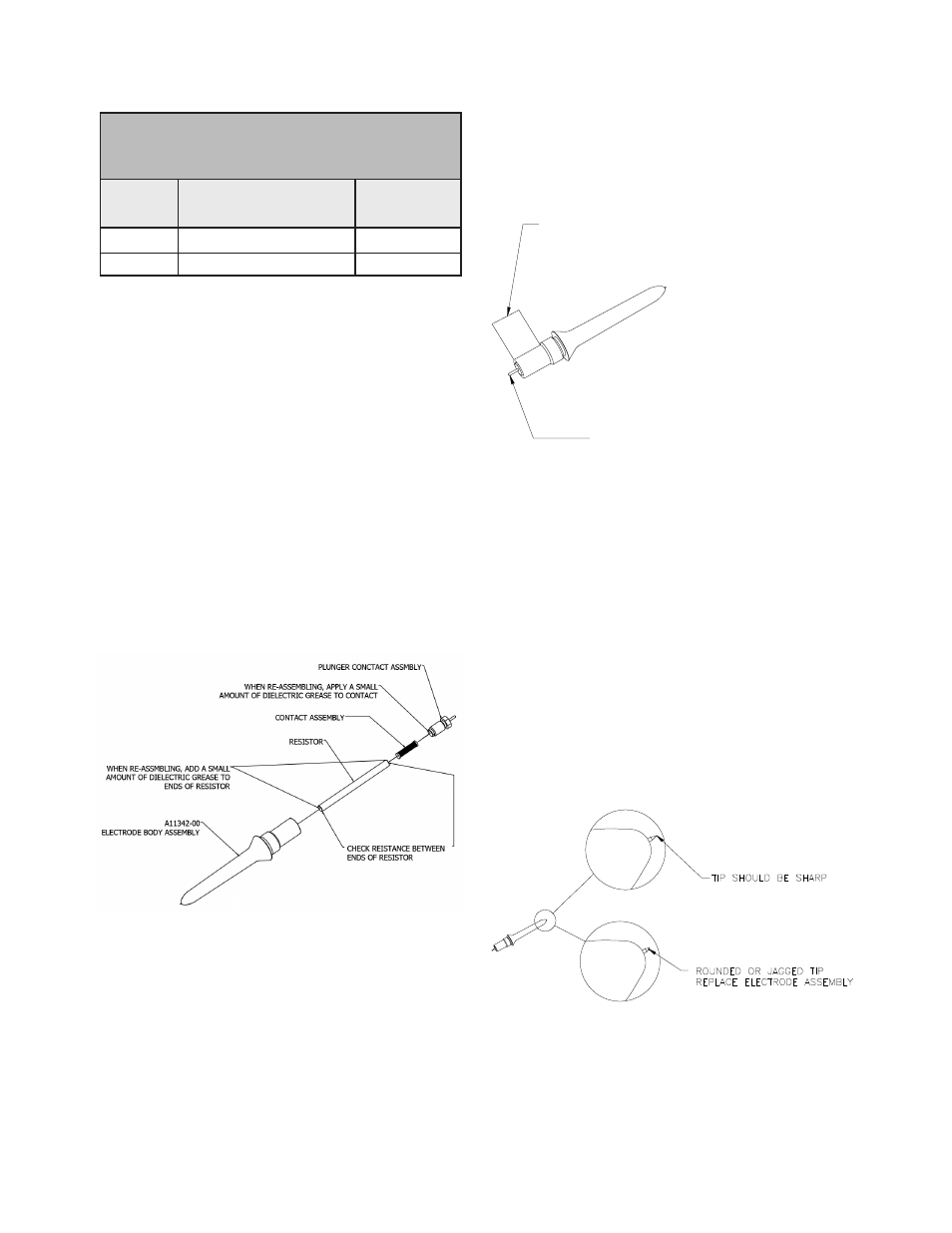

If reading falls out of this range, disassemble

electrode assembly and check reading of resistor

only. If reading is in the acceptable range, discard

the electrode body (A11342-00) and replace with

a new one. Rebuild electrode assembly as follows:

apply a small amount of dielectric grease to each

end of the resistor, slide resistor into the electrode

body (A11342-00). Install the contact assembly

after the resistor. Finally, apply a small amount of

dielectric grease to contact area of plunger contact

assembly. Thread plunger contact assembly into

electrode body by hand until it stops. Hand tight

is good enough. Over-tightening will damage the

electrode body (see Figure 55).

209-231 megohms

133-147 megohms

ELECTRODE ASSEMBLY

RESISTANCE READING

Resistance Reading

(Megohms)

A11343-02

A11343-03

Part #

Sea Level

Above 5000 ft.

Used At

(locations)

Before Installing A New or Used

Electrode Into the High Voltage Ring

Replace the dielectric grease in the area as shown

in Figure 56. A thin film is all that is required.

Figure 55: Disassembly / Assembly Electrode

Assembly

Figure 56: Replacing Dielectric Grease

Electrode Tip Inspection

Inspect the electrode tips weekly or sooner. If

a collision has occurred, immediate inspection

is required. The tip of the electrode should be

sharp and pointed. After time, the tip will wear.

If the tip is rounded or worn jagged it must be

replaced. Depending on use, electrode tips will

last 3-6 months. The electrostatic field generated

by these electrodes are very important to maintain

paint transfer efficiency, pattern uniformity, and

atomizer cleanliness.

Figure 57: Inspection of Electrode Tip

LSCH0009

DIELECTRIC GREASE

(NO GREASE ON THREADS)

ADD A SMALL AMOUNT OF DIELECTRIC GREASE

ON THE END OF THE METAL CONTACT.

RMA-303 Indirect Charge - Maintenance

Ransburg

67

LN-9252-06.4