Ransburg, Disassembly procedures – Ransburg RMA Indirect A11600 User Manual

Page 53

DISASSEMBLY PROCEDURES

>

The outer protective cover may have to

be replaced more frequently than weekly.

Daily inspection of the amount of paint

buildup on the cover will determine the

frequency of replacement.

NOTE

Atomizer Removal/Replacement

NOTE

>

For re-assembly instructions, use the

reverse of the following disassembly pro-

cedures.

NOTE

>

To fascilitate atomizer removal from

hose manifold, a robot program should be

made that purges all paints and solvents

from the RMA-303. Ideally it would then

position the bell assembly in a bell remov-

al position where the bell cup is pointed

downward at a 30° angle. Any residual

solvents would be contained in the "J

bend" of the robot wrist.

NOTE

>

All o-rings described in the "Mainte-

nance" section of this manual should be

lubricated with a food grade petroleum

jelly or with A11545 lubricant.

W A R N I N G

>

Carefully remove the quick disconnect

ring to insure any residual line pressure

has been relieved to atmosphere.

W A R N I N G

>

Prior to removing applicator fom the

robot, the following tasks must be com-

pleted:

• Robot put into E-stop mode, locked,

and tagged-out.

• All fluid passages are cleaned, purged

out, and depressurized.

• Air turned off.

!

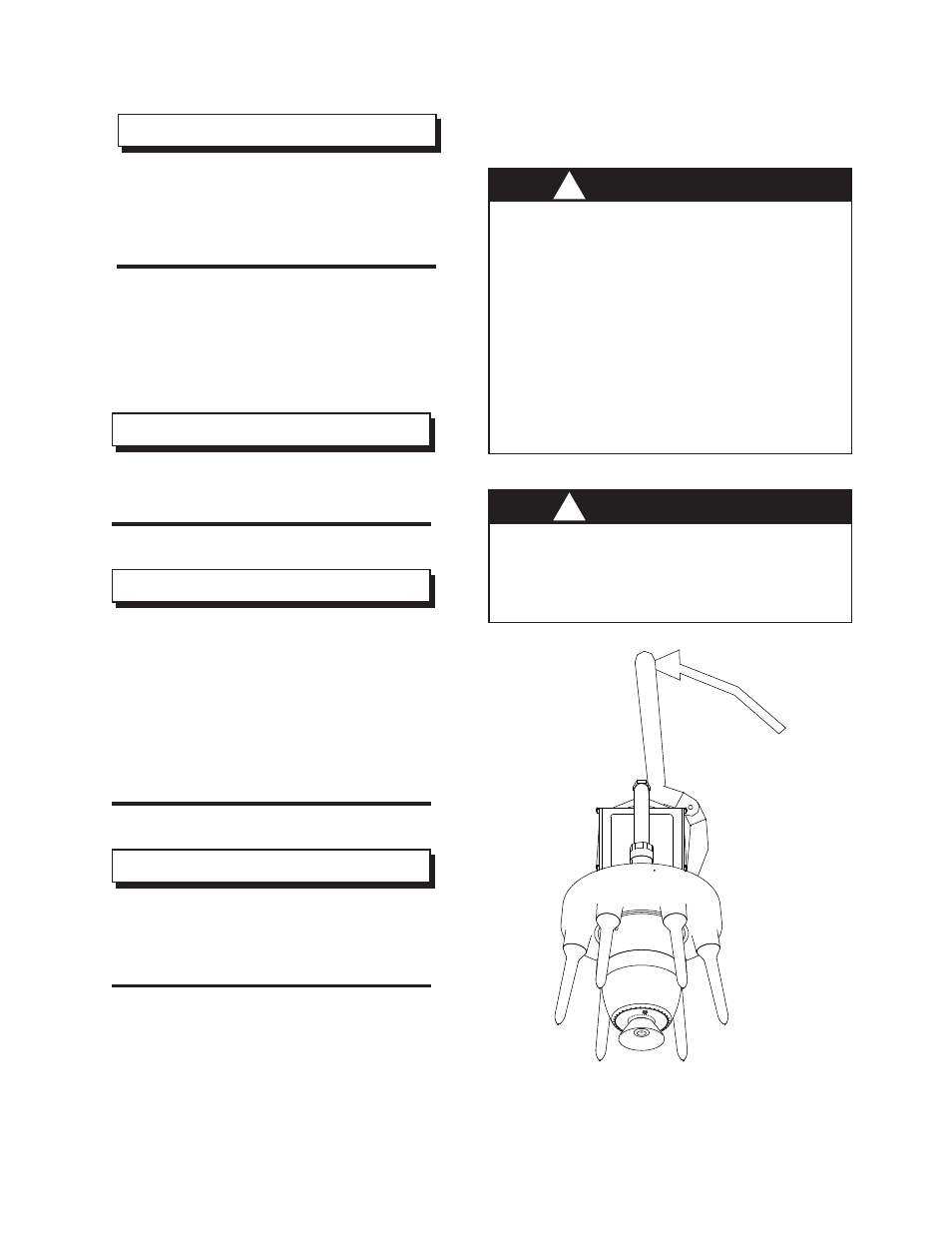

Figure 13: Atomizer Removal from Robot

!

CCW

TO

REMOVE

RMA-303 Indirect Charge - Maintenance

Ransburg

49

LN-9252-06.4