Ransburg – Ransburg RMA Indirect A11600 User Manual

Page 66

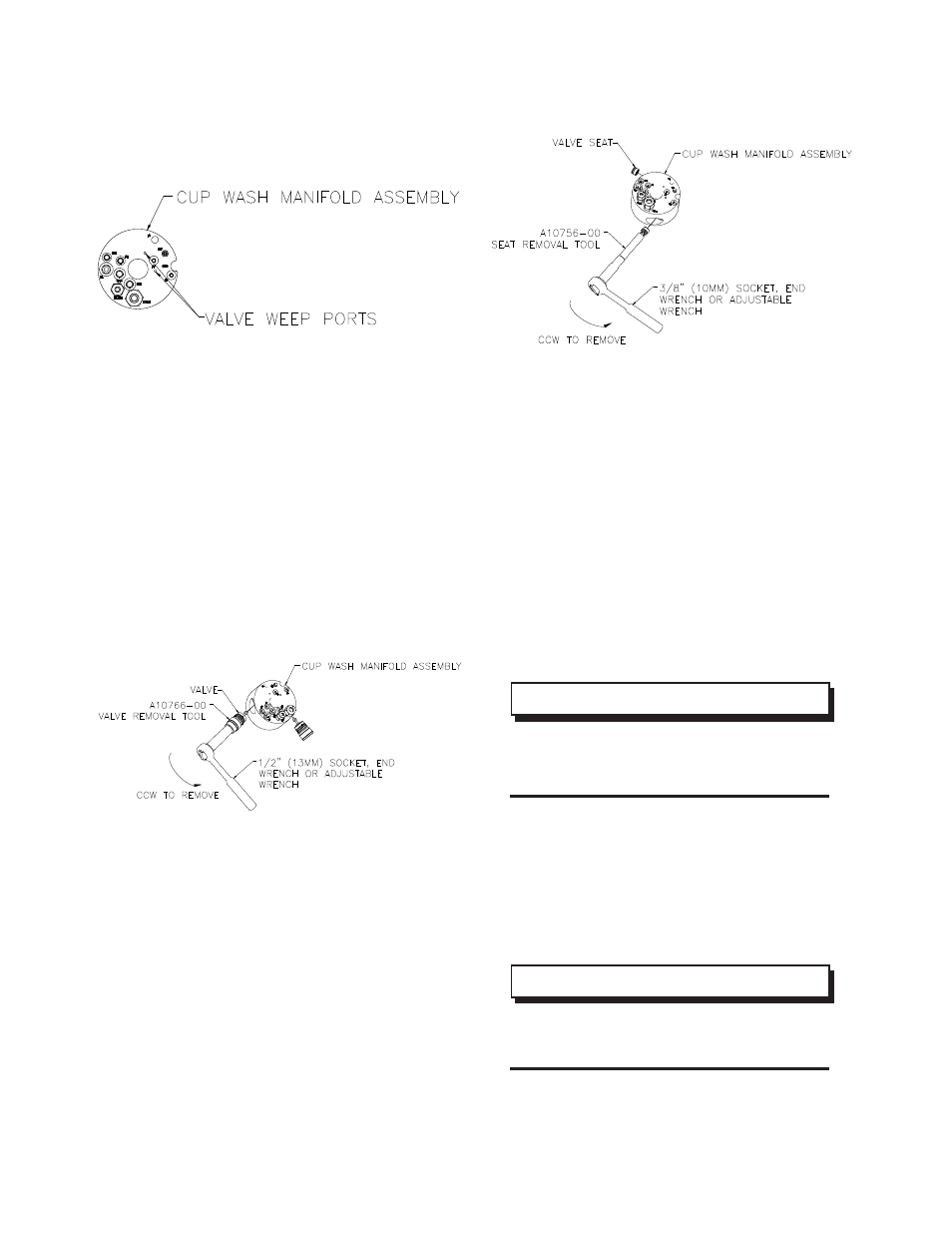

Figure 43: Weep Port Locations

Inspect weep ports for contamination or other visi-

ble leakage around valves. Follow instructions as

follows for damage to valves, seats, or performing

preventative maintenance.

Using the valve removal tool (A11922-00), engage

the four (4) pins on the tool to the corresponding

four (4) hole pattern in the top of the valve. Us-

ing a 1/2-inch (13mm) socket, end wrench, or

adjustable wrench, remove the valve by turning

counter-clockwise.

Figure 44: Valve Removal

Valve and Seat Inspection

Inspect the valves and seats for any build-up or

leakage of materials. Valves should be cleaned

with an appropriate cleaning solvent to remove

the material on it.

>

A seat should not need to be replaced

unless there are indications of valve leak-

age in operation.

NOTE

Replacement

Lubricate the o-ring on the seat assembly using

a suitable lubricant, then by hand, using the seat

removal tool (A10766-00), carefully start the seat

assembly into the pocket of the manifold.

Figure 45: Seat Removal

Valve and Seat Removal/

Installation (Cup Wash Manifold)

Using the seat removal tool (A10756-00), insert

the smaller hex end into the block to engage the

seat hex. Using a 3/8-inch (10mm) socket, end

wrench, or adjustable wrenc, remove the seat by

turning counter-clockwise.

>

Carefully start the seat assembly into

the pocket. It may be easily cross threaded.

NOTE

RMA-303 Indirect Charge - Maintenance

Ransburg

62

LN-9252-06.4