Ransburg, Rma-303 indirect charge - maintenance – Ransburg RMA Indirect A11600 User Manual

Page 62

Cup Wash Manifold Removal/

Replacement (Applicator Off

Robot)

(See Figures 35 and 36)

Removal

Remove the mounting ring by first removing

the break-away ring. Loosen the six (6) 1/4-20

screws (using a flat blade screwdriver) that holds

the break-away ring to the rear plate assembly.

The break-away ring and the mounting ring will

now come off.

Loosen the fiber optic assembly in the rear plate

by loosening the set screw with a 3/32" hex key.

Pull the fiber optic cable from its hole in the solvent

manifold and rear plate assembly. Leave end

loose in the atomizer extension.

Using the tubing removal tool (A11373-00), se-

lect the appropriate size end for the tube to be

removed, 8mm or 6mm. The 8mm end will also

fit over the 10mm green turbine air tube. Place

the opening around the tube and press down on

To reinstall, insert open end of A11351-04 assembly

into front of atomizer body and push all the way

through. Install ferrule and fitting over tube and

install at valve manifold end first! Tighten fitting

to a stop, then 1/4 more turn. Next, pull some of

the slack out of the line before tightening the next

fitting and ferrule into the atomizer body. Tighten

to stop and then 1/4 turn more. Next, tighten the

remaining end of the tube into the inner shaping

air ring. Tighten to stop and tighten 1/4 turn more.

the quick release collet. Using your other hand,

pull the tubing from the collet. Remove all tubing

from the collets. Also, remove the fluid tubes held

on with compression nuts.

On the cup wash manifold end, remove the cup

wash line from the manifold by unscrewing the

1/4-inch fitting using a 3/16" end wrench. Leave

line loose in atomizer extension.

Remove the six (6) 6mm screws holding the rear

manifold to the atomizer extension using a 5mm

hex key. Slide the rear plate and cup wash man-

ifold assembly out. All the tubing should come

with the assembly except the fiber optic and cup

wash line.

Replacement:

To replace the cup wash manifold and rear plate

assembly, you must have all the tubing in place on

the cup wash manifold except the fiber optic and

the solvent wash line. Lightly tape the tube ends

together to ease installation. Slide the tubing into

the atomizer extension, helping the tube make the

bend at the front end of the atomizer extension.

Align the locating pin and the rear plate with the

locating hole of the atomizer extension. Install the

six (6) 6mm socket head screws. Tighten to 15

lbs•in (1.69 Nm) torque (see Figure 35).

Reattach all tubing at the atomizer end, reinstall

the fiber optic cable into the rear plate. Tighten

set screw to 10 lbs•in (1.13 Nm) torque.

Install the mounting ring onto the atomizer ex-

tension, threads facing rearward. Install the

break-away ring. Align the four (4) locating dowel

pins with the corresponding four (4) holes on the

break-away ring. Install the six (6) 1/4-20 stainless

steel screws. Tighten to 15-20 lbs•in (17 - 2.3 Nm)

torque. If you are using the optional plastic break-

away screws, tighten evenly to 5 lbs•in (.56 Nm)

torque. The break-away ring must lie flat against

the face of the rear manifold.

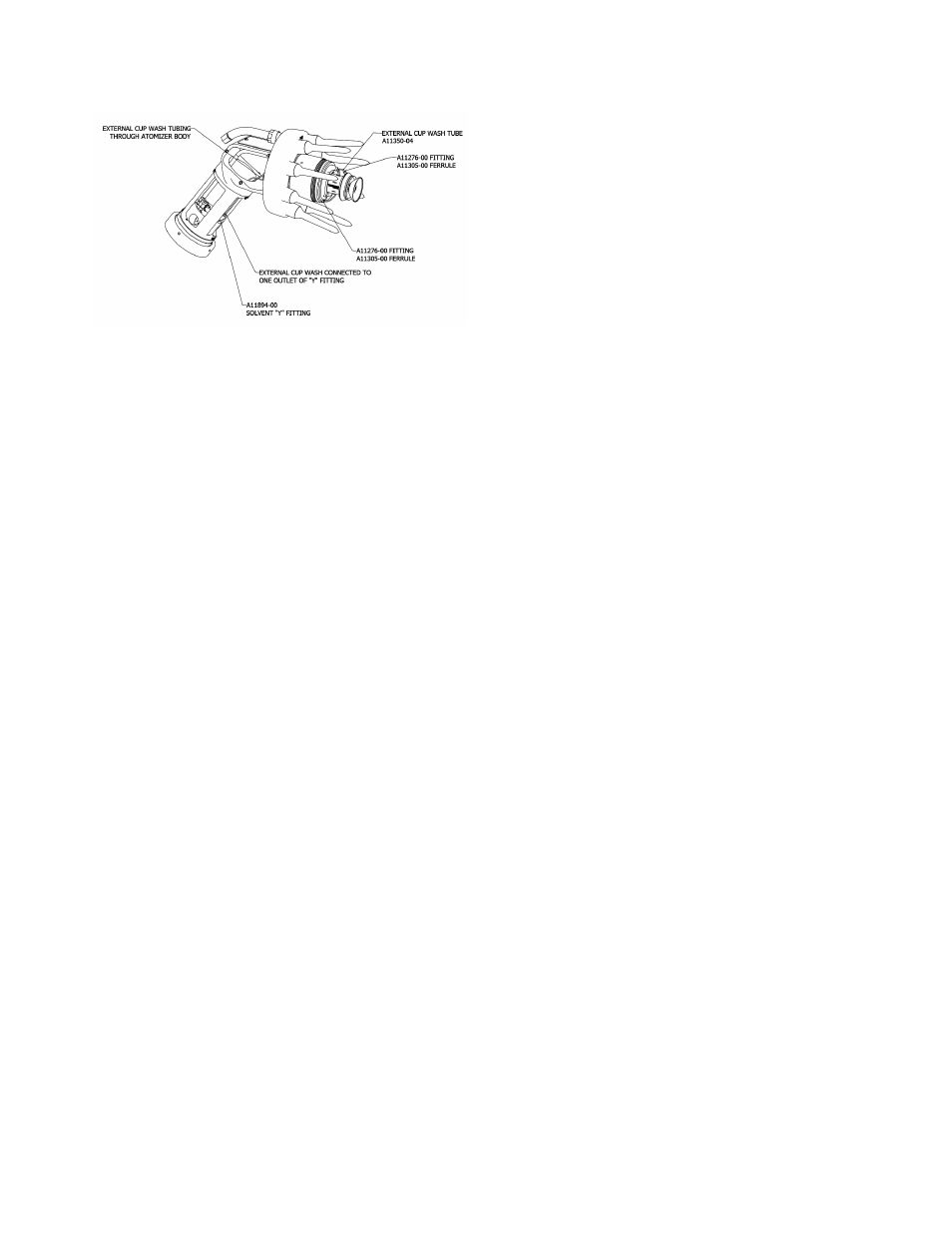

Figure 34: External Cup Wash Tube Route

RMA-303 Indirect Charge - Maintenance

Ransburg

58

LN-9252-06.4