Ransburg, Rma-303 indirect charge - operation – Ransburg RMA Indirect A11600 User Manual

Page 41

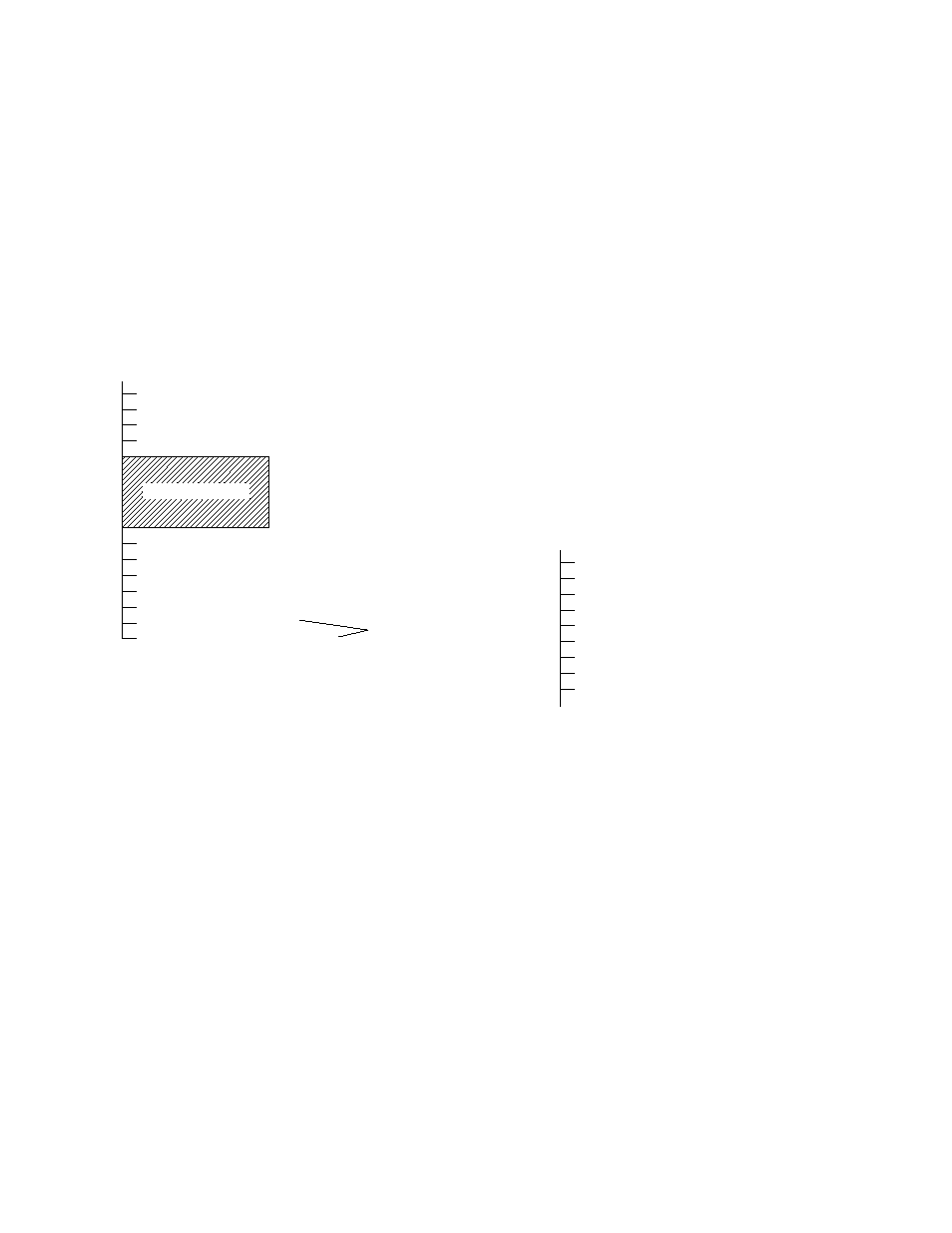

Figure 10: Typical Color Change Sequence

DUMP TRIGGER ACTUATED

SOLVENT ON (1 SEC DURATION)

AIR ON (2 SEC DURATION)

SOLVENT ON (1 SEC DURATION)

AIR ON (2 SEC DURATION)

DUMP TRIGGER OFF

PAINT TRIGGER ON

SOLVENT ON (1 SEC DURATION)

AIR ON (4 SEC DURATION)

SEQ

U

ENC

E EV

ENT

BELL TO SPEED

INTERNAL SHAPING AIR ON

VOLTAGE ON OR UP FROM SETBACK

FLUID TRIGGER ON

SPRAY TARGET

VOLTAGE OFF OR SETBACK

FLUID OFF

INTERNAL SHAPING AIR TO SETBACK FLOW

BELL TO SETBACK SPEED

INT/EXT CUP FLUSH

COLOR CHANGE SEQUENCE

AND/OR

SEQ

U

ENC

E EV

ENT

INTERLOCK -HV OFF

Figure 9: Typical Paint Sequence

4. Maintain solvent pressure of 100-150 psi (689-

1034 kPa). Maintain air push pressure at 80-100

psi (552-689 kPa).

5. Use an alternating trigger sequence of solvent/

air to create a chopping effect. Always insure that

the last step in the sequence is an air push.

6. A typical sequence is .3 seconds solvent, 1.7

seconds air push; repeat 3 times. This sequence

may be modified for other paint and applications.

Sequence Event Explanation:

1.

Bell to Speed - This is accomplished by a set

point command from either the PLC, robot, or other

input device, through the I/O module.

2.

Shaping Air On - From a setback amount, a

signal is sent to air control to increase direct flow

to a desired level to achieve pattern size, film build,

transfer efficiency, etc. Shaping air should never

be set below 70 slpm (2.6 SCFM) air flow rate.

3.

Voltage On - The voltage is turned on from a

signal to the MicroPak. The lag time to full volt-

age may be reduced if a setback voltage is used.

Recommended setback voltage is between 30kV

and 50kV.

4.

Trigger Fluid - An air signal is sent through

the PT line of the tubing bundle. This should occur

when the target is 6-12-inches (152.4-304.8mm)

from the applicator centerline. (Not to be confused

with target distance.)

5.

Voltage Off/Setback Voltage - Immediately

preceeds the trigger off. Using a setback voltage

shortens the cascade voltage ramp up-time.

6.

Fluid Trigger Off - This should occur when

the target is typically 0 to 6-inches (0-152.4mm)

past the applicator.

7.

Shaping Air to Setback - The setback flow

of air should never be below 70 slpm (2.6 SCFM).

8.

Color Change Sequence - Used when color

is changed one to the other. Typical sequence is

shown in Figure 7.

(Note: During this sequence,

the applicator should be moved to a position

to collect the waste material.) The sequence

shown is a starting point for processing, but the

final sequence will depend on the material being

sprayed and the solvent used to purge the appli-

cator with.

RMA-303 Indirect Charge - Operation

Ransburg

37

LN-9252-06.4