Ransburg, Bell cup removal/replacement, Rma-303 indirect charge - maintenance – Ransburg RMA Indirect A11600 User Manual

Page 57

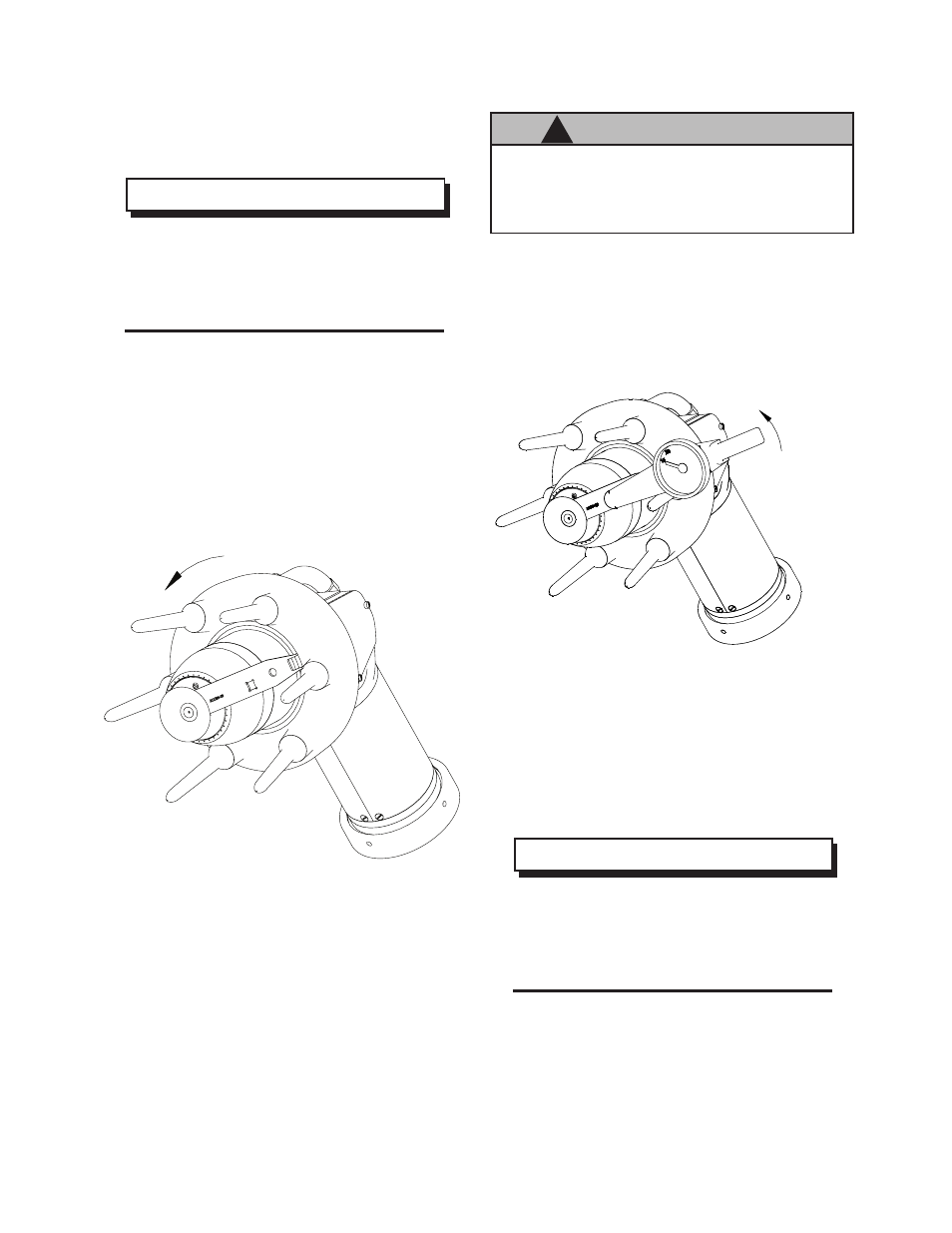

Bell Cup Removal/Replacement

Using the large open end of the wrench (A12061-

00) on the flats of the turbine shaft, carefully hold

the ouside of the bell cup with one hand while

applying a clockwise force to the wrench. The

bell cup is a right hand thread and must be turned

counter-clockwise to remove. Use latex gloves

to obtain a firmer grip on the cup.

> Failure to replace a damaged bell cup

will cause premature turbine failure.

Warranty will not be honored if the bell

cup is damaged.

C A U T I O N

!

Place the bell cup in a safe, secure place. Carefully

inspect the cup for any damage. If there is any

damage to the cup, it must be replaced.

To re-install a cup, position the wrench as shown.

Insert a torque wrench into the square in the

wrench to approximately 50-70 lbs•in (5.65-7.9

Nm) torque. Hold the cup and tighten the torque

wrench in a counter-clockwise direction.

>

The bell cup should always be the first

component removed if any maintenance is

performed. Following the procedure will

minimize the risk of damage to the cup

itself.

NOTE

Figure 21: Bell Cup Installation

>

There is a 3-inch center-to-center

distance between the bell cup and the

3/8-inch socket square on the wrench.

This distance must be factored in when

reading the proper torque on the wrench.

NOTE

Figure 20: Bell Cup Removal

HOLD BELL CUP SECURELY BY HAND.

TURN TORQUE WRENCH COUNTER

CLOCKWISE TO TIGHTEN

TIGHTEN TO 50-70 LBS-IN. (5.65-7.9 Nm)

HOLD WRENCH BY HAND

AND TURN BELL CUP

COUNTER CLOCKWISE TO

LOOSEN

RMA-303 Indirect Charge - Maintenance

Ransburg

53

LN-9252-06.4