Ransburg, Tubing bundle installation, Bundle lubricant – Ransburg RMA Indirect A11600 User Manual

Page 34: Interlocks, Rma-303 indirect charge - installation

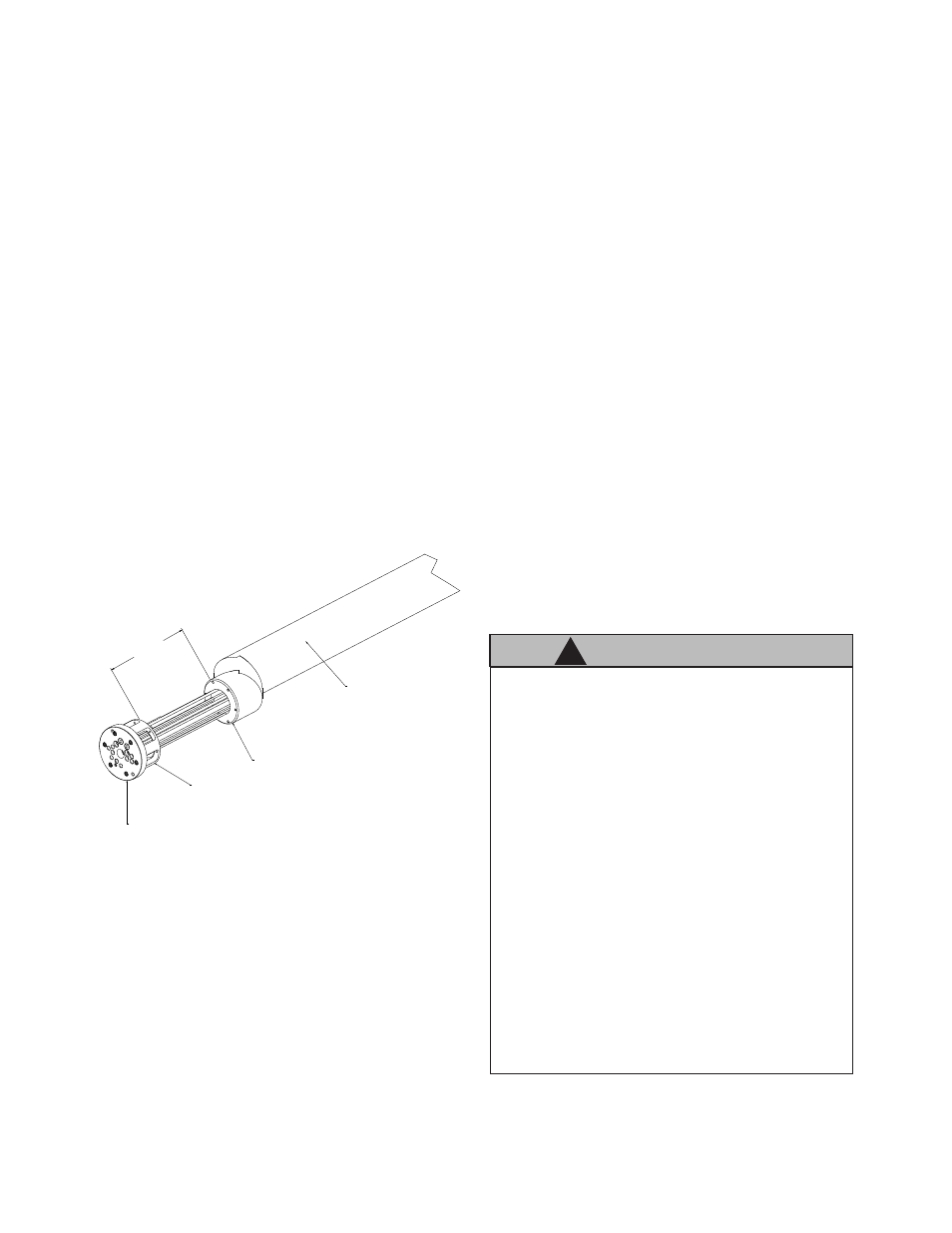

TUBING BUNDLE

INSTALLATION

Typically, the tubing bundle is pulled through the

robot arm from the robot wrist side. Keep the

bundle taped except for the bundle that will be

inside the arm. Pull the tubing through the wrist

and arm, leaving about 250mm (10-inch) of tub-

ing sticking out the front of the wrist plate (see

Figure 6).

Fasten the cable bundle at the exit of the arm. Push

the robot spacer plate and applicator mounting

plate to the robot wrist plate aligning the top dead

center marks of the spacer plate and robot wrist

plate. Fasten using appropriate screws. Install-

ing the tubing bundle in this fashion will increase

tubing bundle life significantly.

Figure 6: Tubing Bundle Installation

BUNDLE LUBRICANT

When the tubing bundle is installed, it should be

lubricated with a generous amount of lubricant to

increase the service life of the tubes. A recom-

mended lubricant is Shell Alvania EP #02. There

are other lubricants that are available for use.

Prior to using a lubricant, insure it is silicone free,

resists heat breakdown, and is compatible with

the materials it will contact. It is recommended

that tubing bundles be re-greased every six (6)

months maximum.

INTERLOCKS

The following system interlocks are required to

prevent equipment damage:

1. Bearing air should remain on at all times and

should be shut off only by turning off the mainair

to the pneumatic control cabinet.

> When the turbine air is turned off, the

turbine will continue to operate or "coast

down" for about two minutes. Provisions

should be made to assure that the operator

waits at least three minutes, after shutting

off the turbine air and before shutting off the

main air supply.

> The bell cup must be removed when making

flow checks. If the paint is turned on when

the bell is mounted and the turbine shaft is

not rotating, paint will enter the shaft and

possibly damage the air bearing. Material

flow checks (flow rate verification) must be

made with the bell cup off and the turbine

not rotating. Normally pneumatic interlocks

will not allow the paint to trigger on when the

turbine air is off.

C A U T I O N

!

250 MM

(10")

APPROX.

ROBOT WRIST PLATE

TYPICAL

ROBOT

ARM

ROBOT

SPACER

PLATE

APPLICATOR

MOUNTING

PLATE

RMA-303 Indirect Charge - Installation

Ransburg

30

LN-9252-06.4