Ransburg, Brake air, Electrostatic voltage – Ransburg RMA Indirect A11600 User Manual

Page 39: Shaping air #2

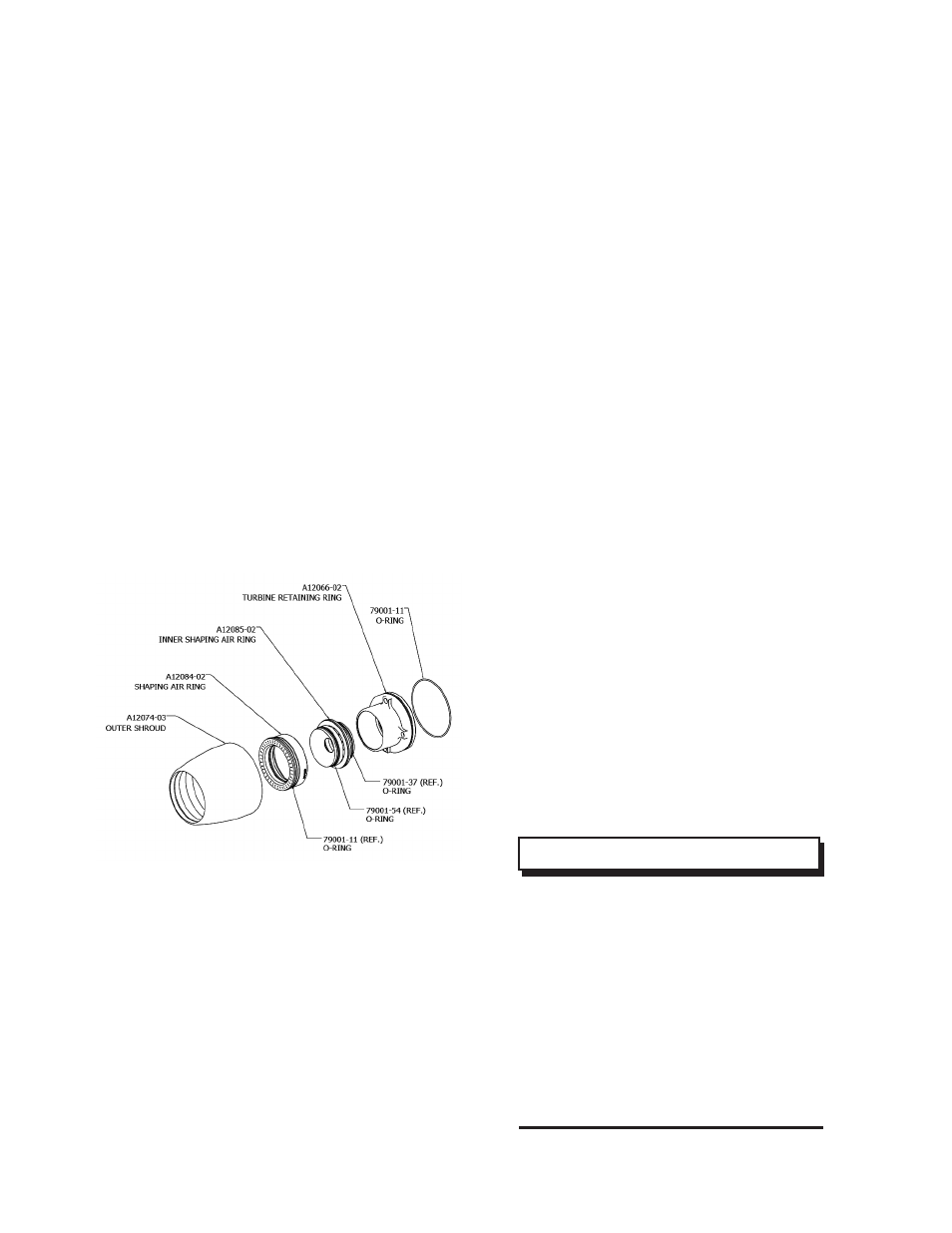

Figure 8: A12089-11 Shaping Air Kit

(Dual Flex Shape Air)

BRAKE AIR

Brake air is used to slow the turbine speed in a

minimum length of time. It is advantageous for

short cycle times during color change, or may be

used to reduce speed or stop the turbine. Never

operate brake air with the turbine air on.

Approximate brake times to reduce the turbine

speed are shown in "Deceleration Time Chart" in

the "Introduction" section. These times are based

on 60 psi (413.7 kPa) and 100 psi (689 kPa) air

pressure at the back of applicator.

ELECTROSTATIC

VOLTAGE

The RMA-303 Indirect Applicator receives its

high voltage via high voltage cable A10560-XX.

The voltage is then passed through eight (8) total

resistors located in the A11343-XX electrode as-

semblies mounted on the A12079-00 high voltage

ring. An ionized field is established between the

probe tips and the electrically grounded bell cup

as well as the electrically grounded workpiece.

Refer to the current MicroPak service manual for

detailed operating instructions, safety cautions,

and settings.

SHAPING AIR #2

(Cut-In Control Air)

A12089-11 Shaping Air Kit (Dual

Flex Air) 65mm Bell Cups Only

As the name implies, both shaping air outlets

supply air that is counter to the rotation of the bell

cup. This combination will provide a pattern size

from 3" - 10" (76mm - 254mm) depending on bell

rotation speed, fluid flow, and air flow. Each set

of shaping air holes are independently controlled.

The inner set of holes are supplied by connecting

the "blue" tube labeled "SAI" on the tubing bun-

dle to a regulated air source. The outer set of

shaping air holes are supplied by connecting the

"gray" tube labeled "SAO" on the tubing bundle

to a regulated source. The air supplies work in

combination with each other to provide desired

results. This combination of shaping air can be

used with any 65mm bell cup.

NOTE

> If paint defects occur, such as fatty edges

or picture framing, reducing the voltage

should be a last resort. To correct the

problem, lead and lag trigger adjustments

should be optimized first.

> The electrostatic voltage applied to the

RMA-303 will affect pattern size, transfer

efficiency, wrap and penetration into cavity

areas. A setting of 30-70 kV is appropriate

for most applications.

RMA-303 Indirect Charge - Operation

Ransburg

35

LN-9252-06.4