Ransburg, Fluid tip removal/replacement, Rma-303 indirect charge - maintenance – Ransburg RMA Indirect A11600 User Manual

Page 60

>

To remove, turn the tip

CLOCKWISE.

The thread on the tip is

left handed.

Replacement

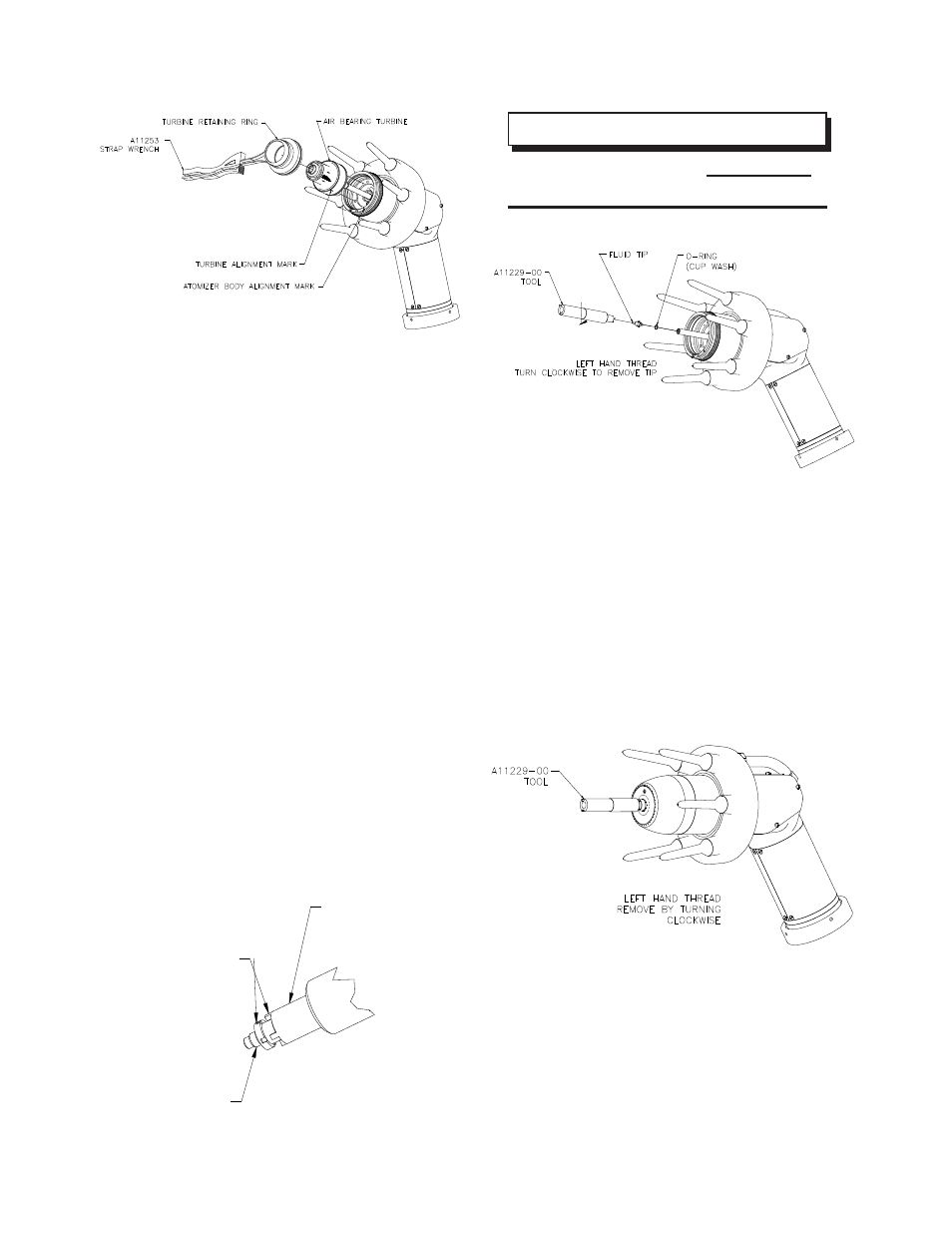

Apply a light coating of o-ring lubricant to all the

o-rings and the threads of the turbine and turbine

retaining ring prior to assembly. Push the turbine

down into the cavity in the atomizer body. Align the

mark on the turbine with the mark on the atomizer

body. Install the turbine retaining ring and o-ring

by hand. Use the spanner wrench to tighten an

additional 1/8-1/4 turn. (Lightly lubricate o-ring

with petroleum jelly.) Check centering of fluid tube.

If fluid tube is centered, the turbine is fully seated.

If not, check tightness with spanner wrench. If

tube is not centered, again remove turbine and

check for causes, such as an o-ring fell off, fiber

optic not fully installed, foreign material on seating

surface, etc. Reinstall and recheck tube centering.

Fluid Tip Removal/Replacement

Removal

To remove the fluid tips, use the tip/tube removal

tool (A11229-00). Insert the tool over the tip and

engage the four (4) prongs of the tool into the

four (4) slots in the tips (see Figures 25 and 26).

Figure 27: Turbine Removal

Figure 28: Fluid Tip Removal

The fluid tip may be removed either with the tur-

bine in place, or the turbine off the unit. Figure

30 shows removing/reinstalling the tip with the

turbine in place.

This allows removal and replacement of the fluid

tip while the applicator is on line.

Check for leaks.

Figure 29: Fluid Tip Replacement

NOTE

Figure 30: Reinstall Fluid Tip

A11229-00

TOOL

FLUID

TIP

ENGAGE

PRONGS

INTO SLOTS

RMA-303 Indirect Charge - Maintenance

Ransburg

56

LN-9252-06.4