Ransburg, Troubleshooting guide (cont.), Aerobell - maintenance – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 66

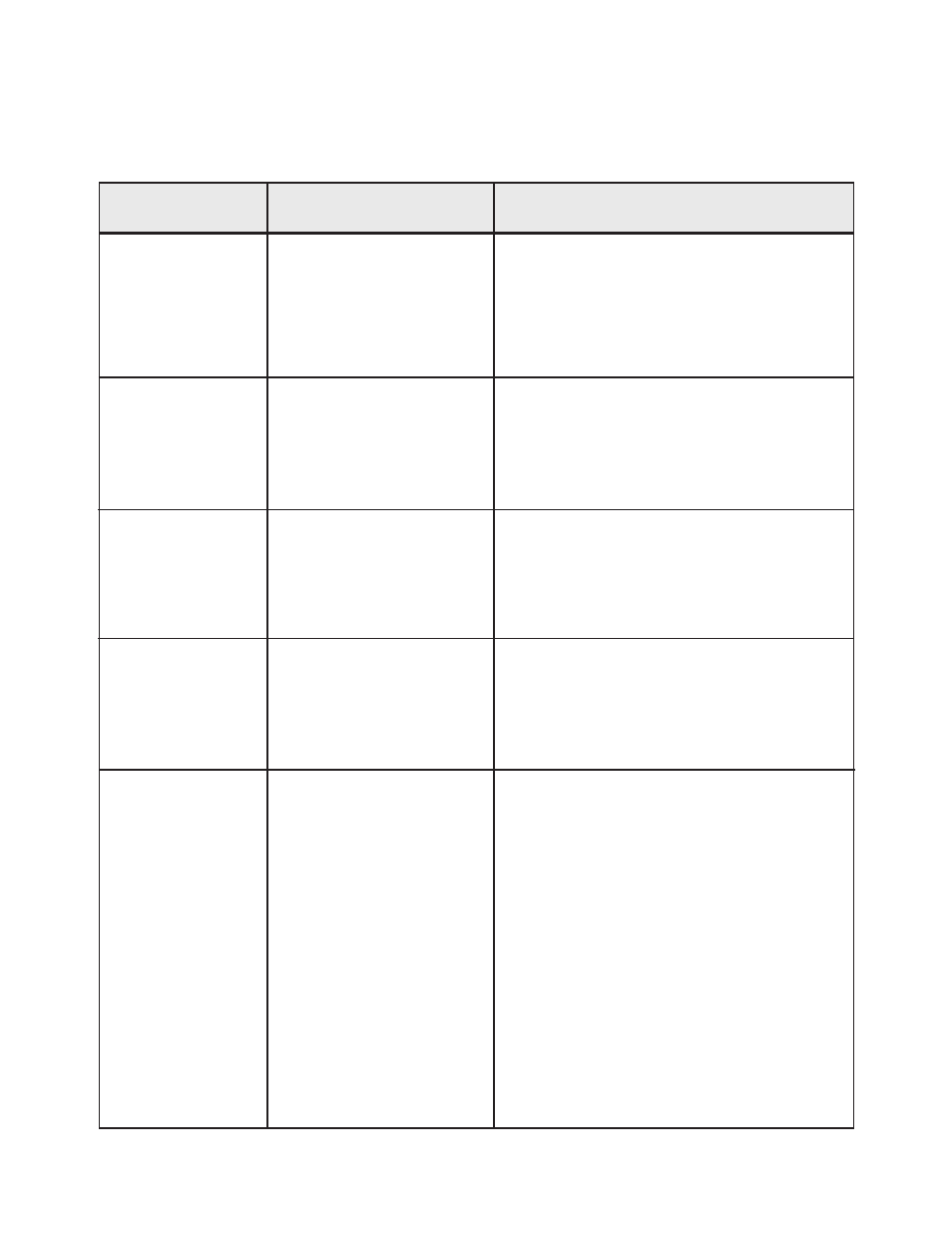

TROUBLESHOOTING GUIDE (Cont.)

General Problem

Possible Causes

Corrective Action

No Fluid Flow

(Cont.)

Continuous Fluid

Flow

Uncontrollable Fluid

Flow

Fluid and/or Air

Leakage Between

the Valve Module

and Mounting Man-

ifold

Fluid Leakage

Around Fluid Valve

4. Clogged fluid tube

5. Plugged bell cup

6. Worn bell cup splash plate

1. Flud valve open

2. Fluid valve seat damaged

or worn (MCV type)

1. Insufficient back pressure

to fluid regulator

2. Fluid regulator does not

control flow

1. Fittings loose

2. O-ring is missing

3. O-ring is damaged

1. Damaged o-ring(s) on

outer diameter of valve

body (MCV style)

2. Damaged or worn needle

seals inside valve assem-

bly.

3. Dirt or debris in valve

4. Remove and inspect fluid tube.

5. disassemble and clean.

6. Check splash plate for worn or missing teeth.

Replace.

1. a. Remove air pilot signal.

b. If still open, replace fluid valve.

2. Replace fluid valve seat.

1. Replace fluid tube with the next smaller inner

diameter size.

2. Disassemble fluid regulator and inspect for

failed components.

1. Tighten or replace.

2. Install o-ring.

3. Visually inspect for damage and replace.

1. Replace o-ring(s).

2. Replace valve assembly.

3. Remove debris. If damage to seat exists, re-

place valve and/or seat.

(Continued On Next Page)

Aerobell - Maintenance

62

LN-9264-08.2

Ransburg