Ransburg, Air filters / element replacement, Bell cup cleanings – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 46

AIR FILTERS / ELEMENT

REPLACEMENT

>

Introducing air which contains oil, mois-

ture, and dirt may cause wear and damage

to the bearings. It is the user's respon-

sibility to monitor the quality of air and to

replace the filter elements as often as nec-

essary. Turbine failure caused by poor air

quality

will not be covered under warranty.

Ransburg Aerobell systems should include a

prefilter(s) and final filters for all air to the Aerobell

unit. The final filter is for bearing air only. All

filters contain elements that must be replaced on

a regular basis to assure clean air. RPM-417 and

RPM-418 filters also contain an automatic drain

and pressure differential indicator.

The pressure differential indicator provides a visual

indicator that pops up (becomes more visible) as

the filter element becomes plugged. Replace the

filter elements when the visual indicator becomes

visible, don’t wait until it pops up fully. As the

elements become plugged, their efficiency drops.

The frequency of filter element change will depend

upon the quality of the plant air. It is recommended

that all elements be replaced at least every 4 to

6 months.

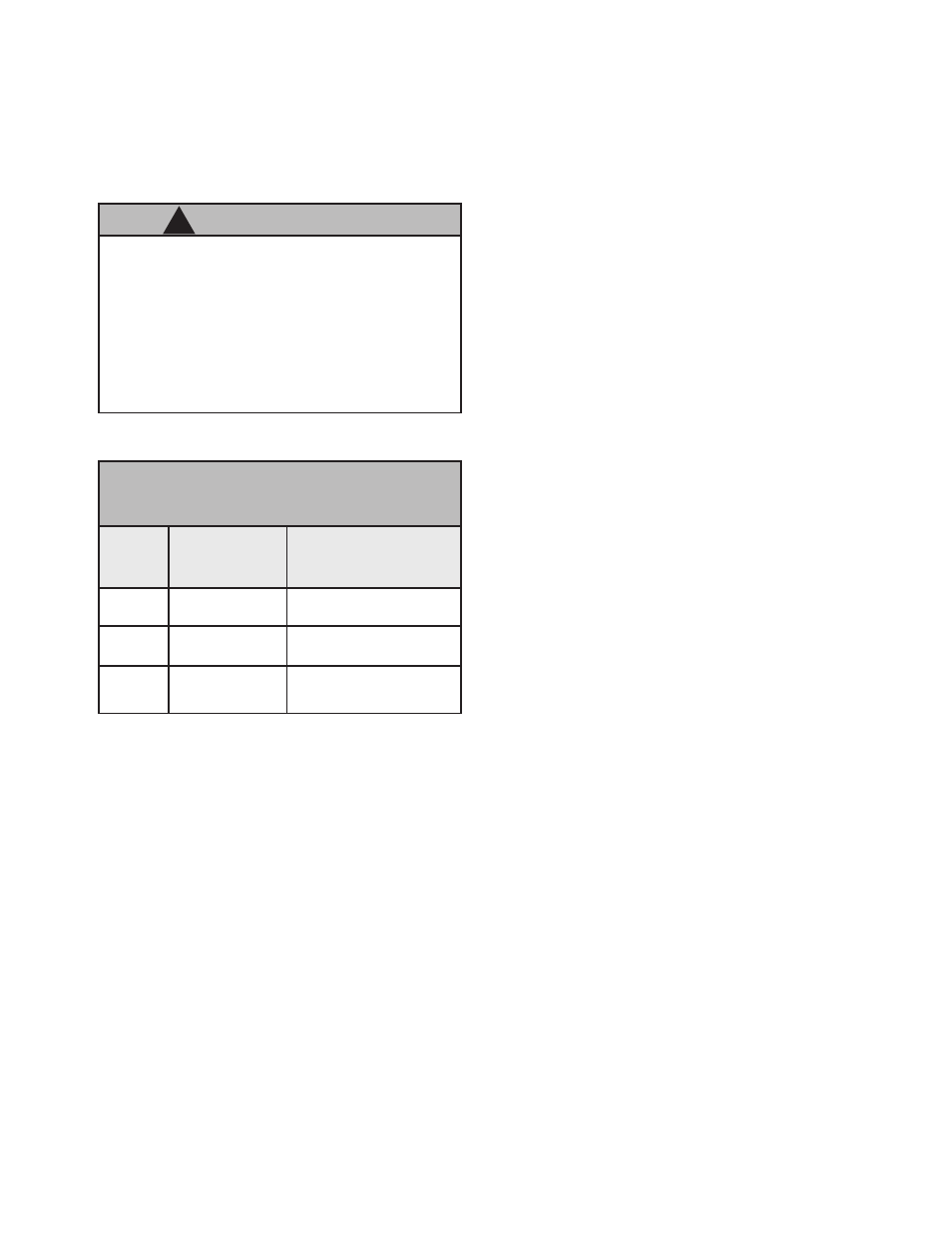

Part#

HAF-5

RPM-32

RPM-33

1

4

8

HAF-515, Pre-Filter

Qty. Elements

Per Carton

Used On

REPLACEMENT ELEMENTS

In plants where heavy amounts of oil and moisture

vapor are present in the air lines, a refrigerated

air dryer may be necessary.

The Aerobell is designed to give dependable

service and extended life. One of the most

important factors in realizing long life is the

quality of air. It is therefore essential for the user

to closely monitor the quality of their air and to

properly maintain the air filters by replacing the

filter elements as often as necessary. (Replace

elements at least every 4-6 months or more often.)

Atomizer Bell Assembly

Inspect the atomizer bell assembly for any damage,

wear, or paint build-up every day.

BELL CUP CLEANINGS

Always verify that high voltage is off and that the

atomizer bell is spinning before performing any

type of bell flush cleaning cycle.

To reduce the risk of fire or explosion, the solvents

used for exterior surface cleaning must have flash

points above 100°F (37.8°C). Since electrostatic

equipment is involved, these solvents must also

be non-polar.

Solvents used for equipment flushing should have

flash points equal to or higher than those of the

coating material being sprayed.

1. The atomizer bell will normally be fully cleaned

during a bell flush cycle. Flushing should be done

before any down time or break in production. A bell

flush cycle may also be required while spraying

batch parts of the same color. Verify that high

voltage is off and that the atomizer bell is spinning

before flushing through the bell.

2. If there is any remaining paint build-up on any

areas of the bell after flushing, the bell should be

removed for hand cleaning. The bell's leading

edge, splash plate, and serration cuts are some

examples of areas for special attention.

C A U T I O N

!

RPM-418, Bearing

Air Filter

RPM-417, Pre-Filter

Aerobell - Maintenance

42

LN-9264-08.2

Ransburg