Ransburg, Brake air, Electrostatic voltage – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 40: Shaping air, Fluid flow rate control

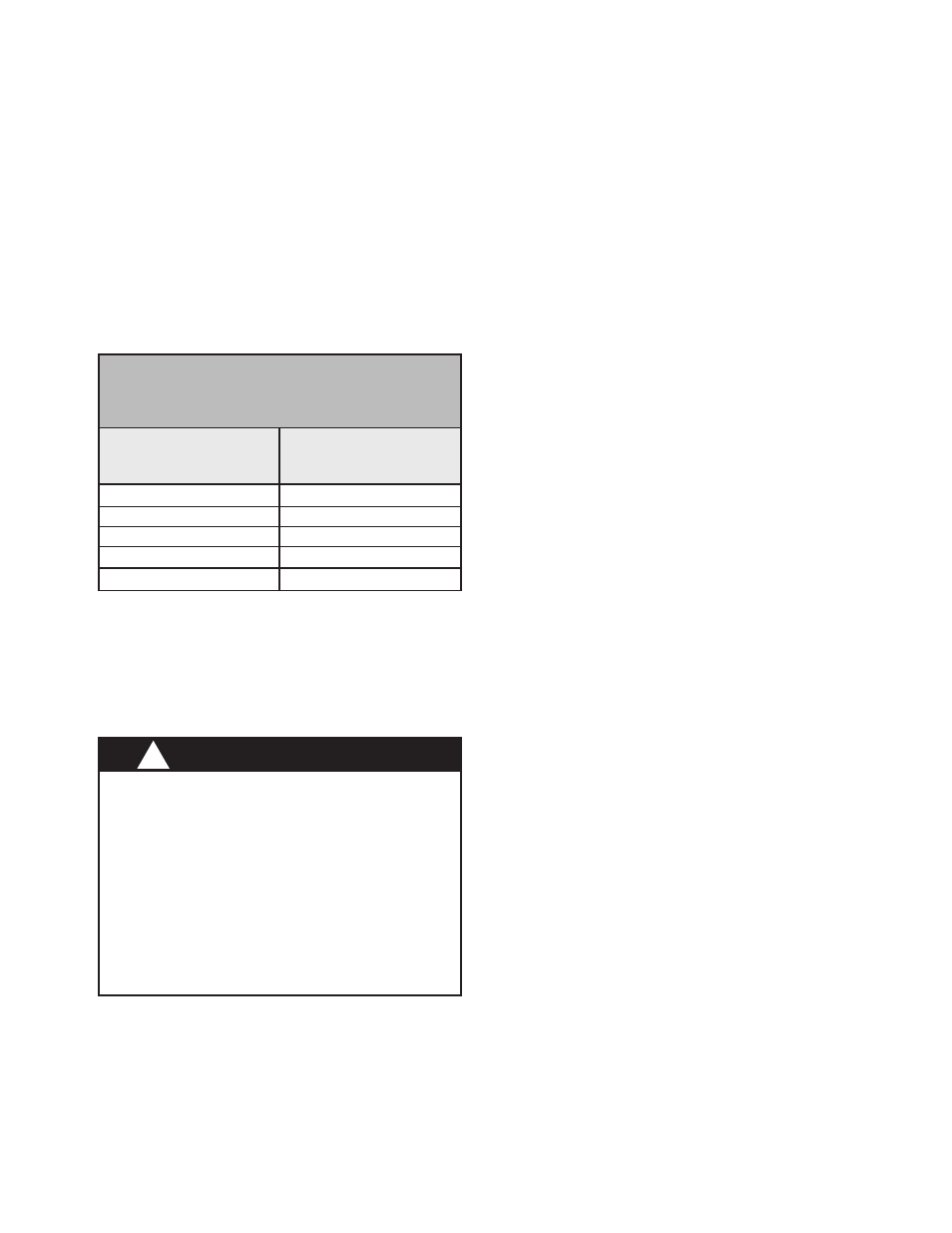

BRAKE AIR

Brake air is used to slow the turbine speed. It is

advantageous for short color change cycle times,

and may be used for stopping the turbine. Use of

the brake involves (1) turning off turbine drive air,

and then (2) turning the brake air on for a short

duration. For example, the air brake will reduce the

turbine speed as shown in "Braking Time" chart.

ELECTROSTATIC

VOLTAGE

Depending upon the power supply model used,

the maximum output voltage of the power supply

can vary. The actual voltage setting will depend

upon various coating application requirements.

The level of voltage applied to the Aerobell plays

an important role with regard to pattern size,

efficiency (wrap), penetration into cavity areas,

and target distance.

SHAPING AIR

Shaping air is used to shape the spray pattern.

The lower the pressure, the wider the pattern, and

conversely, higher pressures result in narrower

patterns. Shaping air does not help atomize the

material, but does assist in the penetration of

atomized particles into cavity areas. Shaping

air should be kept at a minimum consistent with

coating requirements. Excessive shaping air will

cause some atomized particles to blow by the

target not allowing full “wrap,” or paint particles

to bounce back onto the atomizer.

FLUID FLOW RATE

CONTROL

Externally mounted fluid regulators or gear pumps

are typically used to control fluid flow.

The atomizer assembly is equipped with valves

which are pneumatically operated to direct the

flow of paint to either the feed tube or dump line

and to supply an intermittent solvent to clean the

interior of the bell cup.

Three (3) fluid tube sizes are available: 1/16",

3/32", and 1/8" (1.6mm, 2.4mm, and 3.2mm).

>

Electrical discharge of a high electrical

capacitance fluid/paint system can cause

fire or explosion with some materials. If

arcing occurs when a specific coating ma-

terial is used, turn the system off and verify

that the fluid is non-flammable. In these

conditions, the system is capable of releas-

ing sufficient electrical and thermal energy

to cause ignition of specific hazardous

materials in the air.

To Brake From

(RPM)

60,000 to 40,000

60,000 to 20,000

60,000 to 0

40,000 to 20,000

40,000 to 0

Seconds

(Approx.)

3.7

7.5

12.9

4.0

9.0

Braking Time (at 90 psi Brake

Air Pressure)

Brake air should be interlocked so that it is im-

posible for air to be applied to the braking system

while the turbine air is on.

W A R N I N G

!

Aerobell - Operation

36

LN-9264-08.2

Ransburg