Ransburg, Bell cup installation (all), Ccv valve configurations and installation – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 57

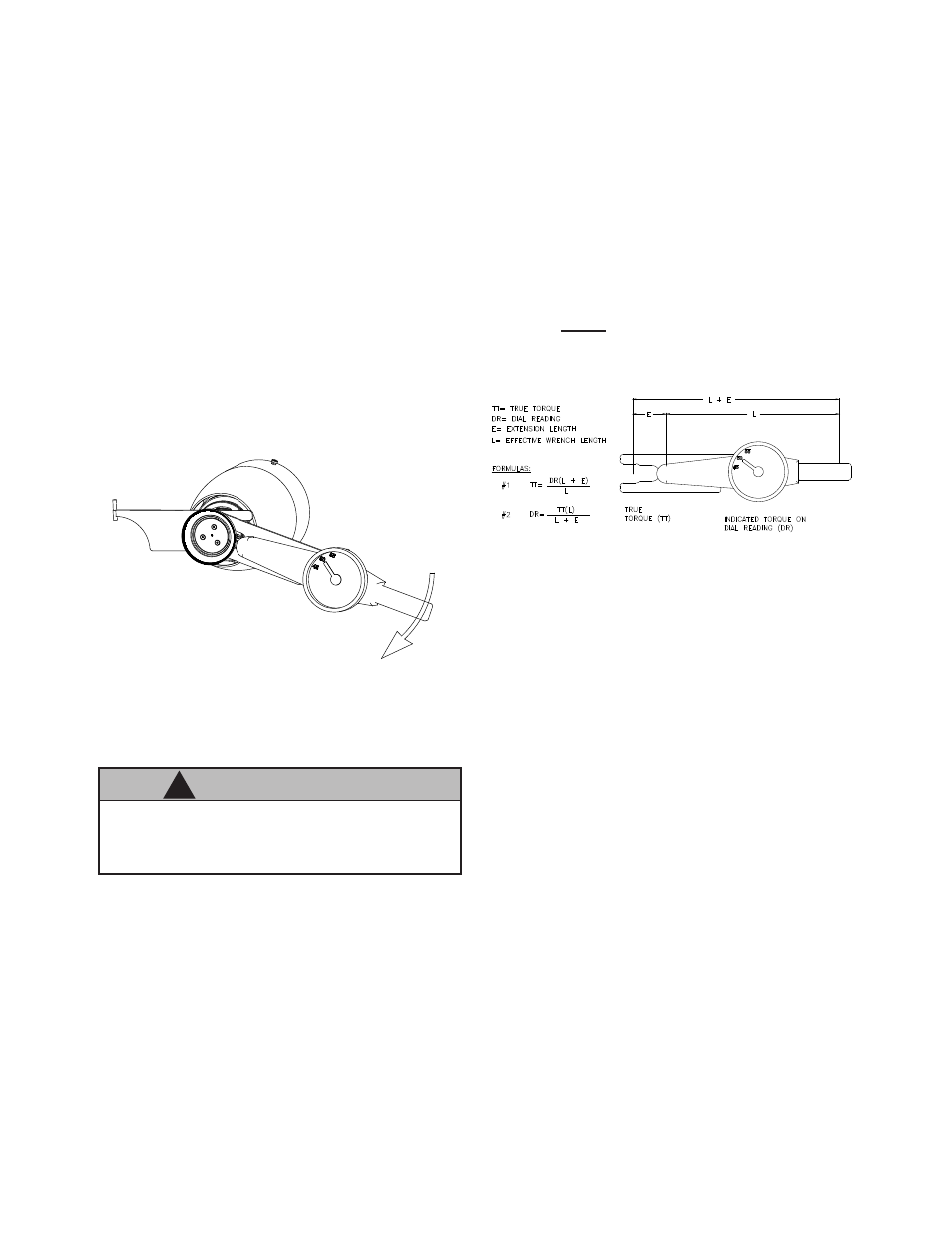

BELL CUP INSTALLATION

(ALL)

Ensure that shaft taper and threads are clean

before installing a bell cup. Also, make sure that

the threads and taper on the bell cup are clean.

Place one (1) RPM-419 wrench on the flats of

the turbine spindle. Use another RPM-419 with

a torque wrench fitted into the 3/8" square of the

wrench. Hold the shaft while applying pressure to

the torque wrench in a clockwise direction. Tighten

bell cup onto the turbine shaft to a final torque of

50-70 lbs•in (5.65-7.91 Nm).

Figure 27: Bell Cup Installation

>

Failure to tighten the bell cup in place

may cause vibration of the applicator and/

or premature turbine failure.

Figure 28: Effective Length Torque Wrench

Example: A desired true torque is desired using a

9-inch effective length torque wrench. Wrench

offset is 1 3/4-inches (1.75-inches).

L = 9-inches

TT

=

50 lbs•in

E

=

1 3/4-inches

DR is dial reading.

DR = 50 (9)

DR = 42 lbs•in

(9 + 1.75)

CCV VALVE

CONFIGURATIONS AND

INSTALLATION

1. If RPM-415 one valve assembly is used, screw

the spanner nut of the valve into the inlet of the

manifold (hand tight).

2. If RPM-408, -409, or -416 valve assemblies

are used, install RPM-61 insert into manifold first.

Tighten spanner nut (hand tight) then tighten per

step #3.

3. It is recommended to leave the valve assembly

hand tight until all air and fluid connection are

made to the rear manifold and to the valves

before tightening the spanner nut, in case the

valve assemblies need to be rotated for clearance

purposes. After all connnections are made, tighten

spanner nut with CCV-7 spanner tool 1/8-1/4 turn

more after valve is seated. You may also tighten

the valve assemblies using a torque wrench fitted

with an adapter for the 1 1/16" spanner nut. Torque

to 132-156 lbs•in (14.9-17.6 Nm).

C A U T I O N

!

Aerobell - Maintenance

53

LN-9264-08.2

Ransburg