Ransburg, Mounting ring removal/replacement, Shaping air manifold removal/replacement – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 61: 70mm style, Aerobell - maintenance

MOUNTING RING

REMOVAL/REPLACEMENT

Remove the three (3) socket head cap screws

with a 3/16-inch hex key wrench. Slide ring off

back of atomizer.

Install mounting ring by lining up the shaping

air outlet port approximately with the exposed

aluminum area on the back of the turbine body.

slide ring onto turbine body. Adjust slightly to line

up the screw holes. Install and tighten screws to

a final torque of 10-15 lbs•in (1.13-1.70 Nm).

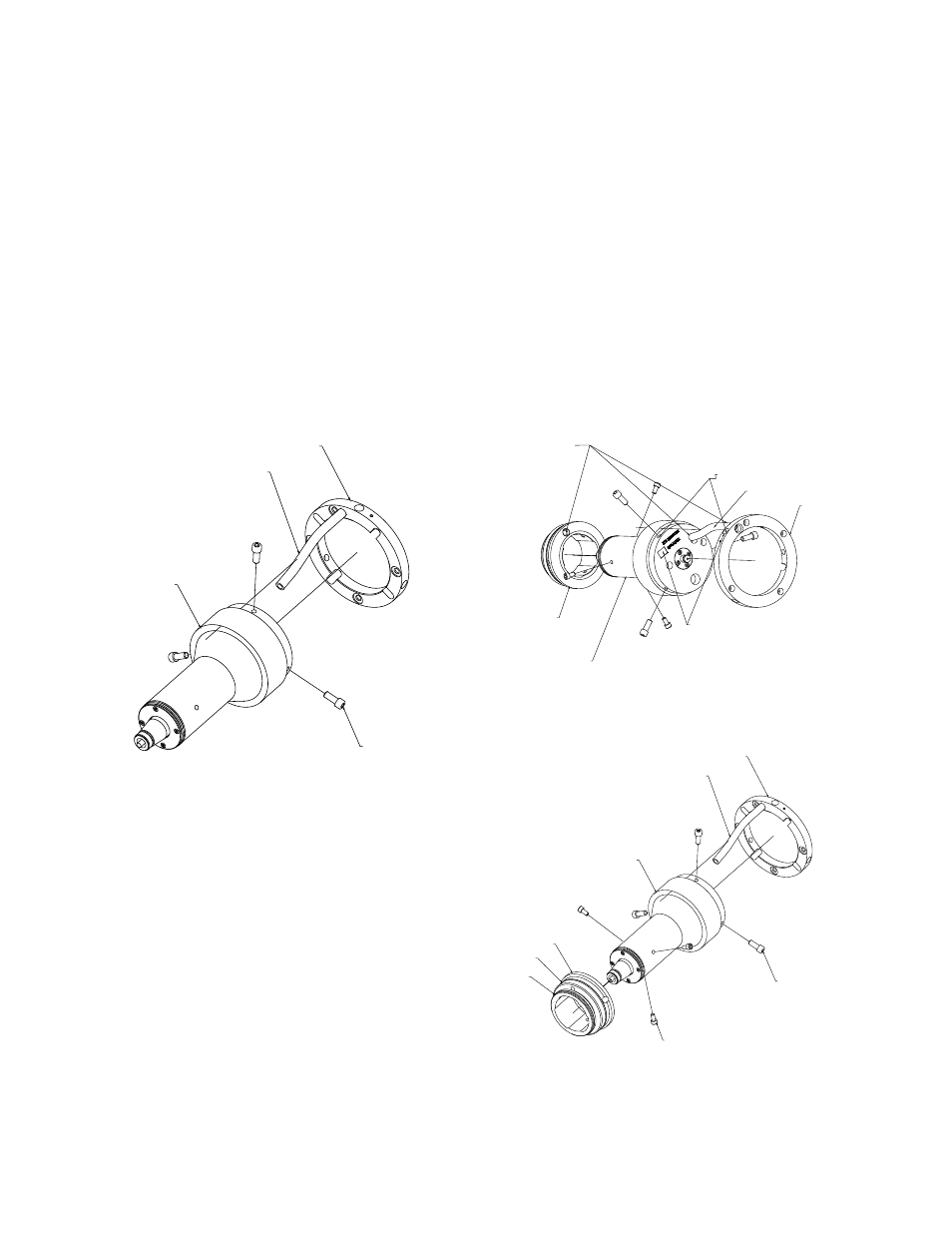

Figure 38: Mounting Ring Removal/Replacement

SHAPING AIR MANIFOLD

REMOVAL/REPLACEMENT

70mm Style

Remove the three (3) socket head cap screws

using a 3/16-inch hex key wrench. Slide manifold

off front of turbine body.

Install the manifold by lining up the shaping air

tube with the shaping air hole in the manifold.

Twist the manifold to line up screw holes. Install

and tighten screws to a final torque of 10-15 lbs•in

(1.13-1.70 Nm).

Figure 39: 70mm Mounting Ring and Shape Air

Manifold Alignment

Figure 40: 70mm Shape Air Manifold

TORQUE TO 10-15 LBS/IN

(1.13-1.70 Nm)

SHAPE AIR TUBE

MOUNTING RING

AIR BEARING

TURBINE ASSEMBLY

MOUNTING SCREW LOCATION

AND ALIGNMENT

ALIGN MOUNTING HOLE NEAR THIS MACHINED AWAY

ALUMINUM AREA AS A QUICK REFERENCE LOCATOR

ALIGN TURBINE SHAPING

AIR MANIFOLD PORT WITH

SHAPING AIR TUBE OR BARB

ON MOUNTING RING

SHAPE AIR MANIFOLD

MOUNTING RING

AIR BEARING TURBINE

ASSEMBLY

SHAPE AIR TUBE

TORQUE TO 10-15 LBS/IN

(1.13-1.70 Nm)

TORQUE TO 10-15 LBS/IN

(1.13-1.70Nm)

SHAPE AIR TUBE

MOUNTING RING

SHAPE AIR MANIFOLD

AIR BEARING TURBINE

ASSEMBLY

O-RING

O-RING

Aerobell - Maintenance

57

LN-9264-08.2

Ransburg