Ransburg, Fluid tube assembly, Seat replacement – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 56: Aerobell - maintenance

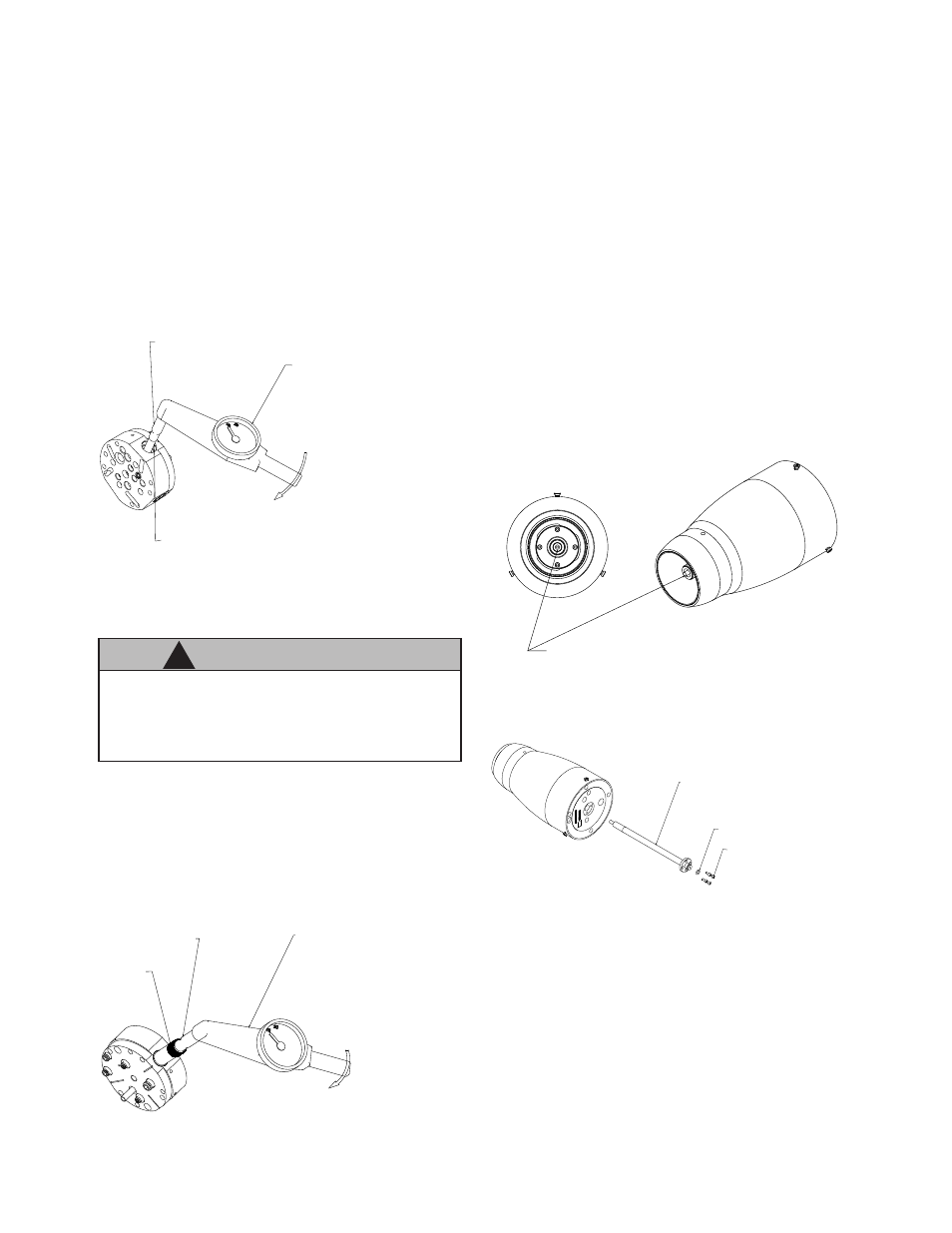

Figure 26b: Fluid Tube Assembly

Seat Replacement

Lubricate the o-ring on the seat assembly using

a suitable lubricant, then by hand, using the seat

removal tool (A10766-00), carefully start the seat

assembly into the pocket of the manifold.

Hand tighten the seat in place. Using a torque

wrench with a 3/8" (10mm) socket, torque the

valve seats to 15-20 lbs•in (1.7-2.3 Nm).

Figure 24: Valve Seat Installation

Figure 25: Valve Installation

>

Always use a torque wrench to torque

the sets in place. Over-torquing the sets

may cause permanent unrepairable dam-

age to the manifold.

Lubricate the valve o-rings with a suitable o-ring

lubricant. By hand, thread the valve into the

pocket in a clockwise direction. Tighten using a

1/2" (13mm) socket and torque to 15-20 lbs•in

(1.7-2.3 Nm).

FLUID TUBE ASSEMBLY

Insert fluid tube into the turbine body bore from the

back side. Install and tighten the four (4) SSF-3137

screws to a final torque of 7-10 lbs•in (0.79-1.13

Nm). Install 79001-05 o-ring on to the exposed

end of the fluid tube. Make sure this o-ring is not

damaged. Leaks will occur if the item is damaged.

Inspect the fluid tube outlet end to make sure it

is centered in the shaft bore. Mis-alignment may

cause fluid tube to touch rotating shaft or bell cup

which may result in turbine failure or fluid tube

damage. If tube is bent or otherwise damaged,

replace with a new part.

Figure 26a: Fluid Tube Assembly

C A U T I O N

!

TORQUE WRENCH

TIGHTEN VALVE SEAT TO A FINAL TORQUE OF

15-20 LBS/IN (1.7-2.3 Nm)

3/8 INCH SOCKET

A10756-00

VALVE SEAT

TOOL

TORQUE WRENCH

TIGHTEN VALVES TO A FINAL TORQUE OF

15-20 LBS/IN (1.7-2.3 Nm)

A11922-00

VALVE

TOOL

1/2 INCH SOCKET

FLUID TUBE CENTERED

RPM-439 1/8 I.D. (3.18MM)

RPM-440 3/32 I.D. (2.36MM)

RPM-441 1/16 I.D. (1.57MM)

FLUID TUBE

79001-05

O-RING

SSF-3137

SCREW

TORQUE TO 7-10 LBS/IN. (0.79-1.3 Nm)

Aerobell - Maintenance

52

LN-9264-08.2

Ransburg