Ransburg, Air heater requirements – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 30

AIR HEATER

REQUIREMENTS

Turbine drive air expands as it moves through

the turbine wheel cavity and as it exits the turbine

from the exhaust port. This expansion will cause

cooling of the exhaust air and the surfaces it

contacts. This same expansion cooling can occur

across the shaping air exit ports. This cooling

effect can cause surface temperatures to fall

below the dew point of the booth, which will result

in condensation on the interior and exterior of the

atomizer, machine, and its components. It is even

possible that the temperature of the supply air

may be below the booth dew point, even without

additional expansion cooling.

Condensation is especially probable in waterborne

applications when booth temperature and relative

humidity levels are typically maintained very high.

This condensation will allow sufficient conductivity

of the surfaces such that they act as an erratic

ground source potential. This can cause damage

to the equipment.

It is therefore, a requirement that turbine exhaust

air temperature be maintained above the booth

dew point to prevent condensation from forming

on atomizer surfaces. Doing so will eliminate

moisture as a potential defect in painted surfaces

as well as extending equipment life. Thus, it is

recommended that air heaters be installed into the

atomizer air supply lines, i.e. shaping air. The air

heaters must be of sufficient capacity capable of

raising the incoming air temperature at least 40°F

(4.4°C) at a flow rate of 60 SCFM per applicator.

The actual air heater process setting depends on

applicator fluid flow rate load, booth conditions,

turbine airflow settings, and incoming air

temperature. The heater should be set as low

as possible, sufficient to maintain the applicator

surface temperatures above the dew point in the

booth.

Example: With the incoming air temperature at

72°F (22.2°C), an Aerobell with 70mm bell cup

rotating unloaded at 60 krpm has a turbine outlet

temperature drop of approximately 28°F (-2.2°C)

(@ 40 krpm unloaded, ∆T ~ 14°F (-.10°C).

Referring to the ASHRAE Psychrometric chart,

the saturation temperature range (dew point) of

a spray booth maintained at 70-75°F / 65-70%

RH is 62-68°F (21.1-23.9°C / 65-70° RH is 16.7-

20°C). Thus it is almost certain that the surface

temperatures of the applicator will fall below the

dew point of the booth, and an air heater will be

needed in this case.

To prevent condensation, an air heater assembly

should be assembled after the air filters. (Reference

the current "Air Heater Assembly" service manual

for further information.)

> Failure to use an air heater may cause

damage to equipment or ruin the finished

component being processed.

NOTE

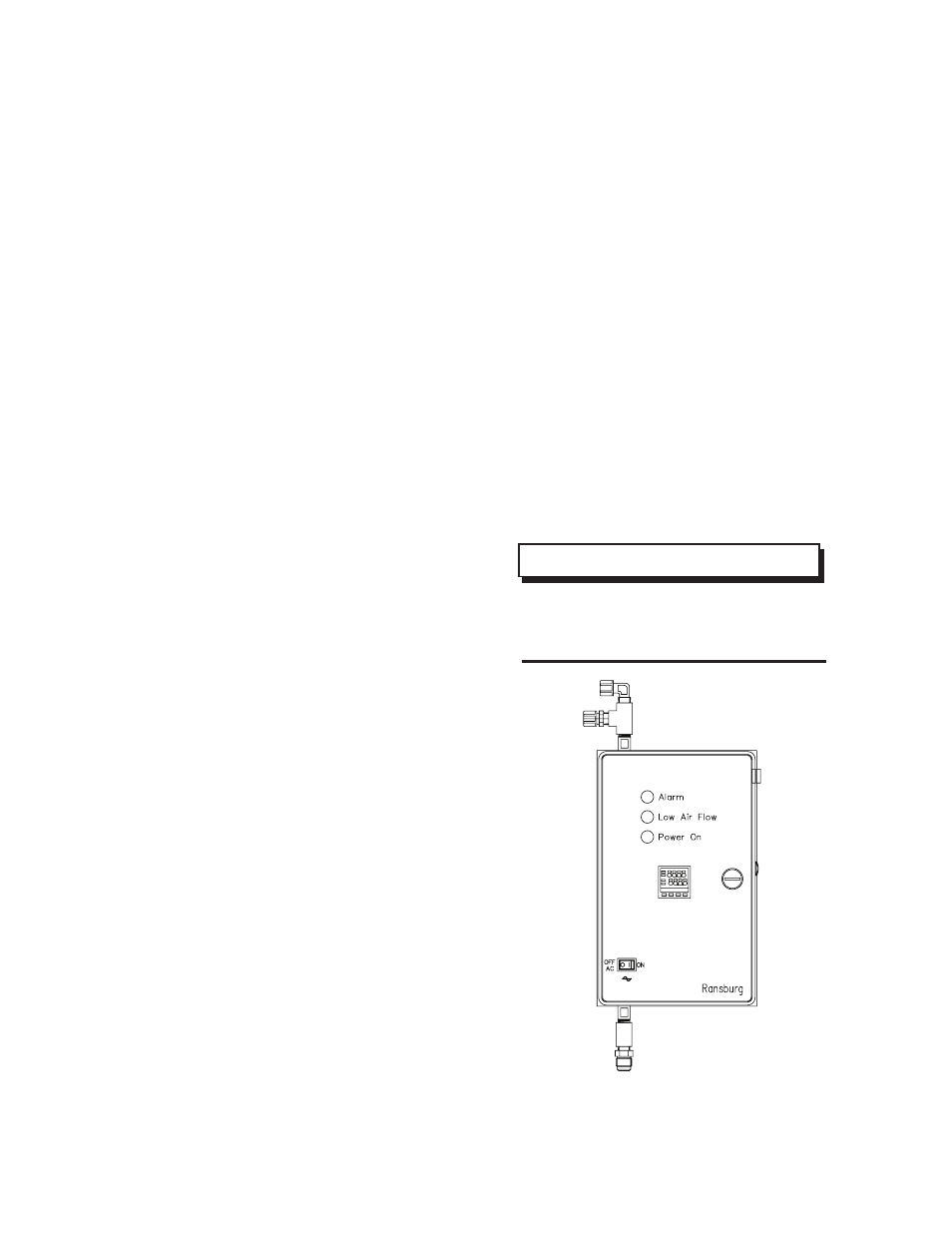

Figure 4: A11065-05 Air Heater

Aerobell - Installation

26

LN-9264-08.2

Ransburg