Ransburg, Disassembly procedures – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 50

Inspect Bell Cup Daily

Check for signs of damage such as nicks, heavy

scratches, dents, or excessive werar. Replace

the cup assembly with any of these conditions.

Atomizer Bell Cup Removal,

Disassembly, Cleaning, and Reas-

sembly

• Remove the shaping air cap by unscrewing

counter-clockwise. Use an RPM-419 wrench

to aid in removal.

• To remove atomizer bell, place RPM-419

(wrench) over flats of shaft to lock shaft.

Unscrew atomizer bell by hand turning

counter-clockwise.

• If the atomizer is tight and can’t be removed

by hand, use the second RPM-419 ( wrench)

to place over the wrench flats of the atomizer

bell.

If the splash plate of the atomizer bell cup needs

to be removed, do not use a hex key with a

ball end. This will cause the head to strip or

"round-out" prematurely. Use a 1/16" hex key

with a squared-off end for best results. Before

removing the three (3) flat head screws, make

sure the sunken hex of the screws are cleaned

out to full depth. Push the splash plate off its

seat from behind using a plastic bolt to prevent

damage to the plate. Once the screws are

removed, they must be discarded and replaced

by new ones. When reassembling, tighten

screws to 2-4 lbs•in torque (0.23-0.45 Nm).

DISASSEMBLY

PROCEDURES

>

Mean time to repair entire assembly is

60 minutes.

NOTE

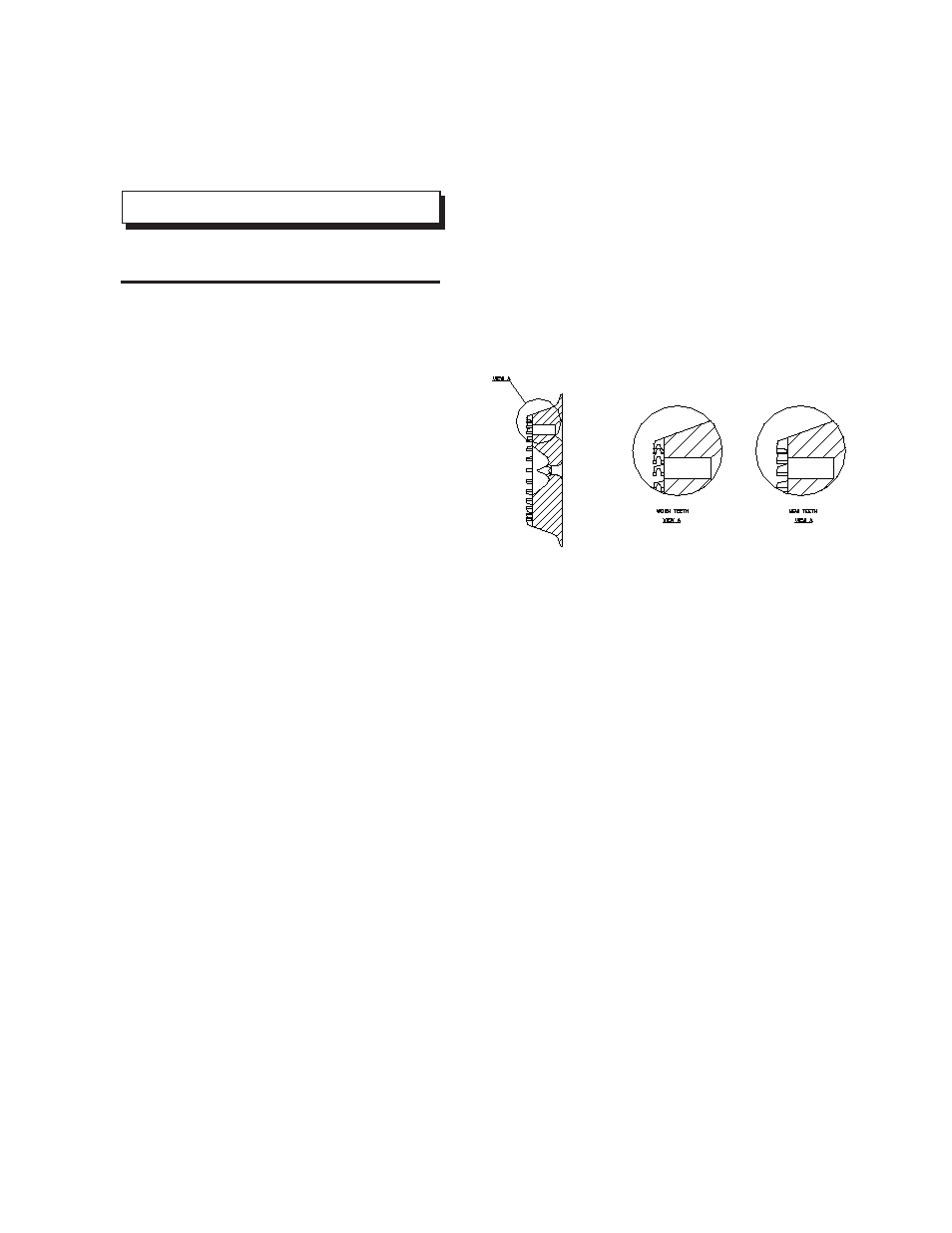

Inspect the splash plate, screws, and bell

cup for wear. Check splash plate teeth for wear.

If teeth are missing or severely undercut,

replace splash plate and screws (see Figure 10).

Pay special attention to the center four holes

in the splash plate. Look for erosion between

the holes. Replace any part if necessary.

Figure 10: Worn Splash Plate Teeth

• Before reassembling the atomizer bell, ensure

the tapers of the shaft and bell which mate are

totally clean, as well as the shaft and bell

threads.

• Place RPM-419 (wrench) over wrench flats of

shaft to lock the shaft.

• Screw atomizer bell onto shaft in clockwise

direction. Torque 50-70 lbs•in (5.65-7.91 Nm)

• Reinstall shaping air cap into shroud. Note when

screwing RPM-4 in place, it will become tight

after approximately 2 1/2 turns. At this point,

use the RPM-419 (wrench) to tighten further.

The RPM-4 will break free and become loose

again and can then be tightened down fully until

it bottoms against the shroud.

Aerobell - Maintenance

46

LN-9264-08.2

Ransburg