Troubleshooting guide, Ransburg, Aerobell - maintenance – Ransburg Aerobell (Std.) Rotary Atomizer A12381 User Manual

Page 63

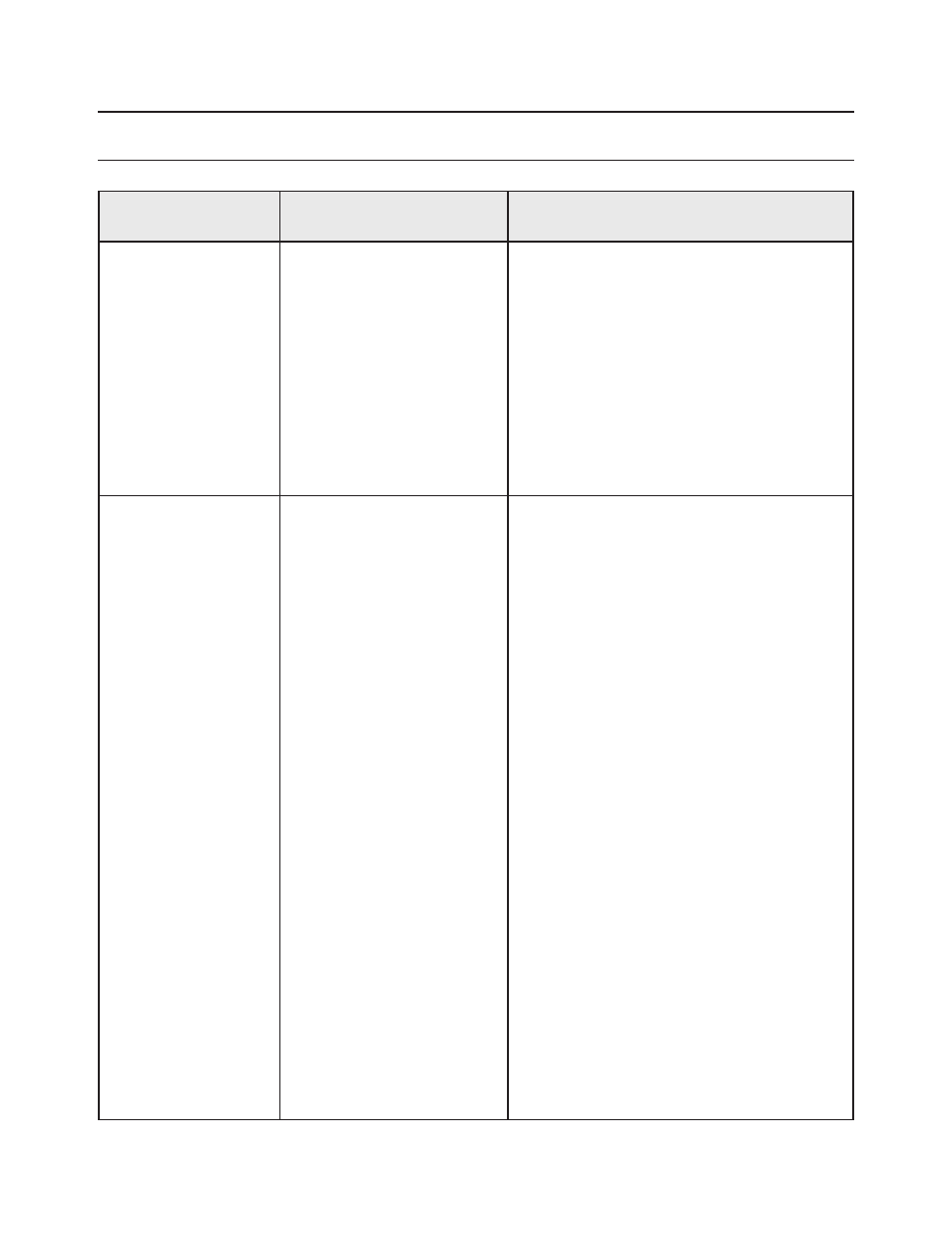

TROUBLESHOOTING GUIDE

General Problem

Possible Causes

Corrective Action

Bad Spray Pattern

Low or No High

Voltage

1. Bell cup damaged

2. Low voltage

3. Bad fluid regulator

4. Paint lodged in shaping air

ring

5. Damaged shape air parts

6. Plugged holes in cup

1. High current draw

2. Solvent valve is actuated

3. a. Loss of low voltage

cable connection between

MicroPak and cascade

b. Loss of cable between

atomizer and Voltage

Master power supply

4. Improper limiting current

and voltage settings

5. Atomizer grounding out

(usually indicated by high

current draw or by Micro-

Pak over-current fault

light)

6. Faulty low voltage connec-

tions (usually indicated by

MicroPak feedback fault

light)

1. Replace bell cup.

2. See "Low or No High Voltage" below.

3. Repair or replace regulator in system.

4. Disassemble and clean.

5. Replace parts.

6. Disassemble and clean.

1. Paint resistivity to be .1 MΩ to ∞ (solvent-

borne direct charging).

2. Remove solvent valve air pilot signal (high

voltage must be interlocked with the sol-

vent valve air pilot signal to prevent solvent

flow while high voltage is energized).

3. Inspect connections.

4. To re-adjust settings, refer to "MicroPak

and Voltage Master 2" operating manuals.

5. a. Clean atomizer externally with non-polar

solvent.

b. Check the atomizer for internal fluid-

leaks.

c. Check for fluid leaks at quick-disconnect

mounting.

d. Check for arcing (usually indicated by

sparking sounds).

6. Check low voltage connection at MicroPak

and cascade.

(Continued On Next Page)

Aerobell - Maintenance

59

LN-9264-08.2

Ransburg