Ransburg, Vector r series classic applicators - maintenance, Attaching barrel to handle – Ransburg Vector R Series Classic 79520 R90 Waterborne User Manual

Page 44

Vector R Series Classic Applicators - Maintenance

40

Ransburg

AH-06-02.12

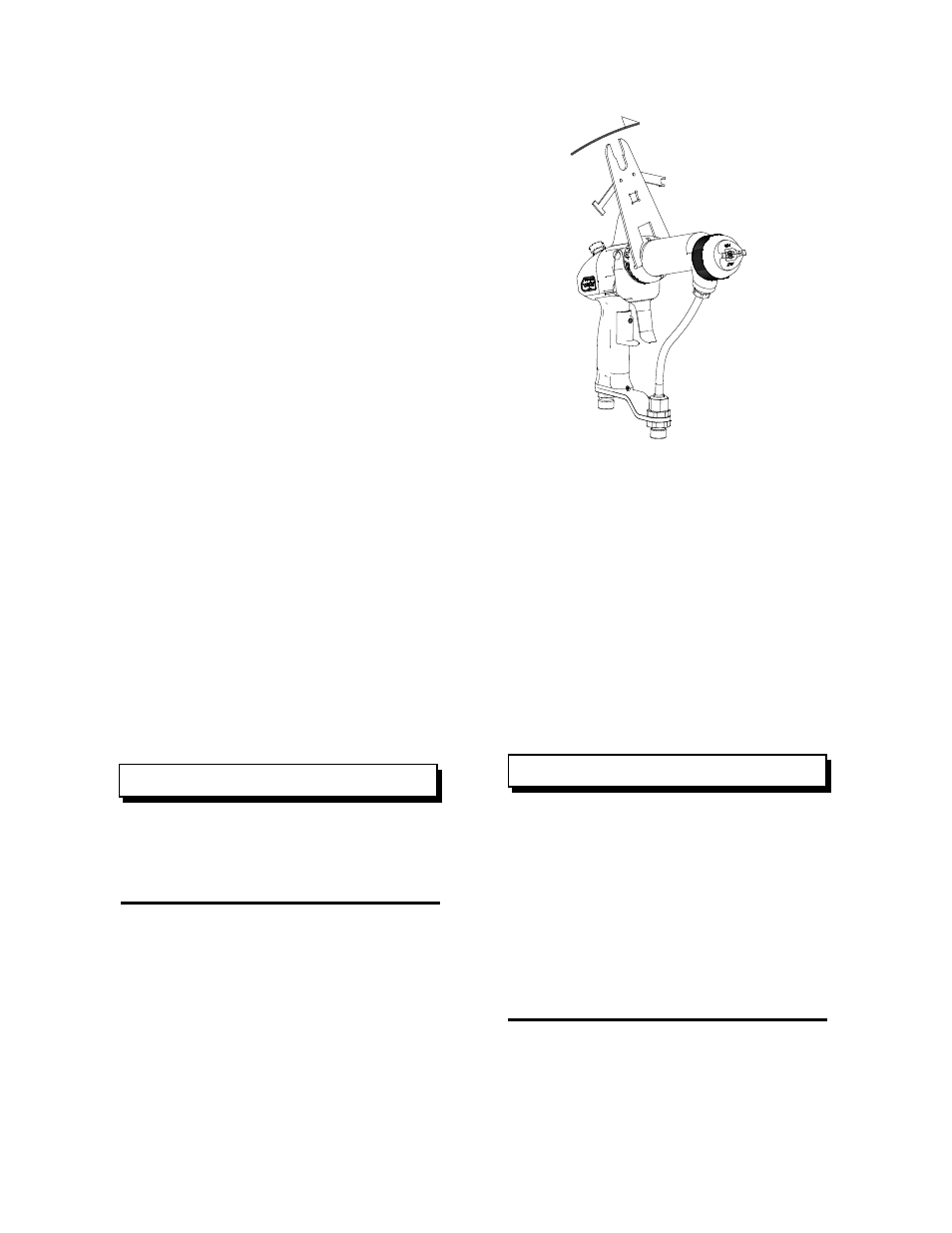

Attaching Barrel to Handle

1. If the barrel retaining nut has been removed,

it will have to be reinstalled before the barrel can

be attached to the handle.

2. Place the retaining nut over the rear of the

barrel and slide it as far forward as possible.

3. Spread the retaining ring and place it onto the

barrel. Starting at one end, lift the retaining ring

over the captive ridge and spiral into place.

4. Place the large hole of the gasket over the nee-

dle shaft and onto the base of the barrel packing

chamber.

5. While holding the barrel with the air nozzle

pointing downward, install the needle shaft spring

into the spring retainer. Align the rear end of

the barrel assembly with the matting area of the

handle assembly, and the needle shaft spring with

the spring recess in the handle. Slide the barrel

into the handle cavity until it is seated against

the gasket. Ensure the needle shaft spring seats

properly into the handle recess.

6. While holding the barrel in place, screw the

retaining nut onto the handle by hand and then

tighten using the special multi-purpose wrench.

Torque the retaining ring to 8-10 lbs•ft

or after hand tightening, torque an ad-

ditional 1/6 to 1/8 turn using the special

multi-purpose wrench.

NOTE

7. Check the spacing between the back of the

spring retainer and the handle. It should be about

1/8 inch. If not, check for one or more of the fol-

lowing:

• Gasket has been left out

• Loose retaining nut

• Loose fluid nozzle

• Improper adjustment of the trigger adjustment

nut and spring retainer

8. Secure the trigger with the two (2) shoulder

screws.

Figure 20: Barrel to Handle Assembly

The needle shaft travel

MUST be

checked. The air valve stem must be

engaged and moved back slightly before

the trigger engages the trigger adjustment

nut. If this does not occur then the trig-

ger adjustment nut and/or the trigger set

screw must be adjusted. The 11/16 inch

dimension is only a starting place for trig-

ger adjustment and can be altered to ob-

tain proper triggering sequence.

NOTE

C W