Ransburg, Vector r series classic applicators - maintenance, Cleaning and inspection – Ransburg Vector R Series Classic 79520 R90 Waterborne User Manual

Page 41: Reassembly

Vector R Series Classic Applicators - Maintenance

37

Ransburg

AH-06-02.12

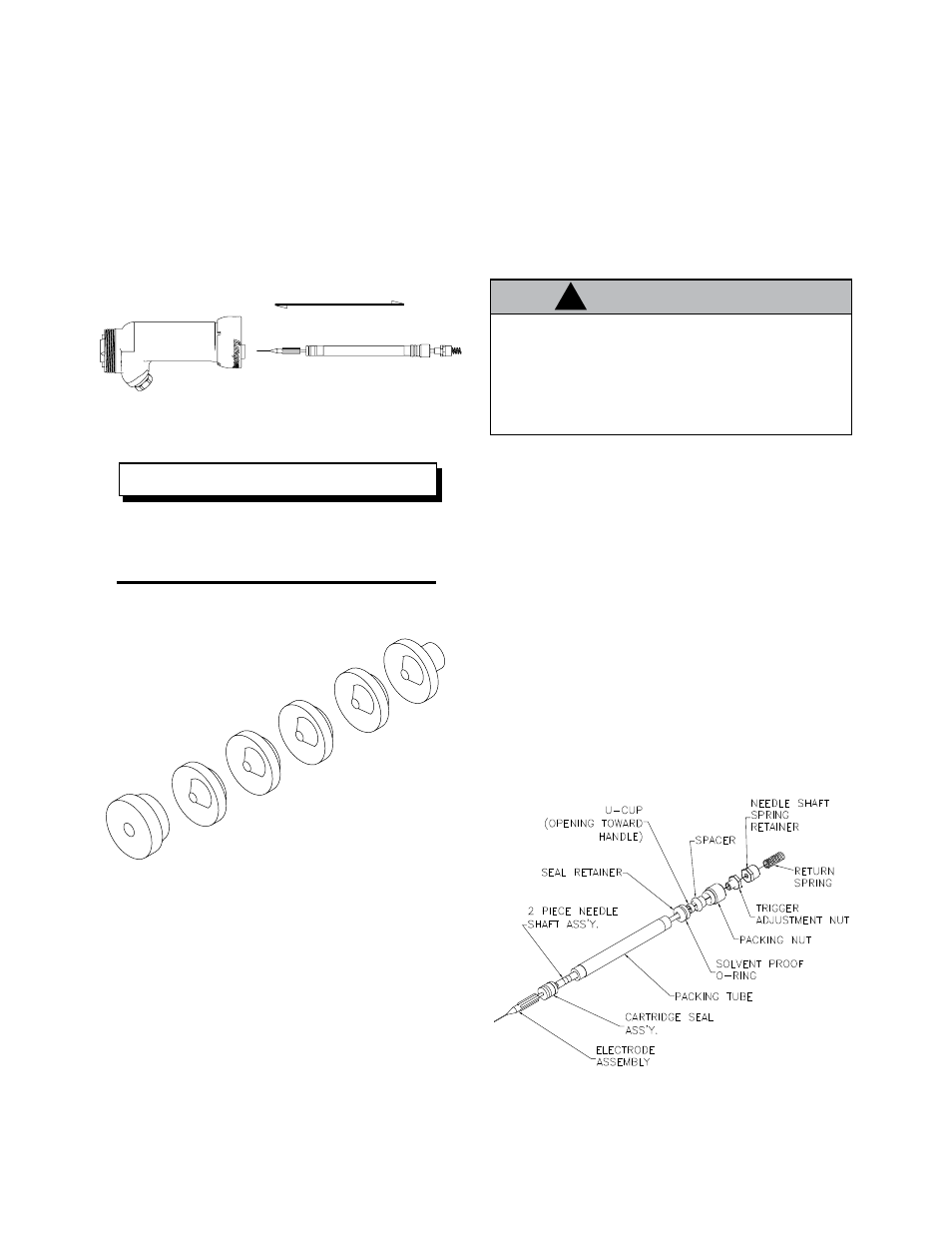

Figure 14: Needle Shaft Insert/Removal

4. Remove the trigger adjustment nut if it was

required when pulling the needle shaft from the

barrel packing chamber. Then remove the packing

nut, spacer, rear seal retainer sub-assembly, and

packing tube from the rear of the needle shaft.

The spring loaded u-cup and o-ring can now be

re-moved from the rear seal retainer.

If the spacer and seal retainer do not

separate easily, wedge a knife blade be-

tween them and pry them apart.

NOTE

Figure 15: Chevron Seal Assembly

5. Unscrew needle/electrode from shaft and slide

the male chevron adapter, the chevron seals and

female chevron adapter off the shaft (see Figure

15).

6. Remove retaining ring and air cap from barrel.

7. Loosen the fluid nozzle using the special

multi-purpose wrench and unscrew it by hand to

remove.

Cleaning and Inspection

1. Clean the packing chamber of the barrel with a

suitable solvent and a soft bristle bottle brush.

DO

NOT submerge or soak the barrel in solvent.

If the chamber has dry paint in it and cannot be

cleaned out, the barrel

MUST BE REPLACED.

2. Examine the plastic section of the needle shaft

and the packing tube for signs of carbon tracking.

Also, inspect the air passages and packing cham-

ber of the barrel for signs of scratches, additional

carbon tracking, or dried paint. Shine a small

flashlight into the front of the barrel to highlight

any damage in these areas.

3. From time to time it is desirable to test the elec-

trical integrity of the 70430-01 resistive electrode

(see "Needle/Electrode Resistance Testing" in the

"Maintenance" section).

Reassembly

(Refer to Figures 15, 16, 17, 18, and 19)

Figure 16: Needle Shaft Assembly

(2k Packings)

Soaking or submerging the barrel could

allow solvents into the high voltage section of

the barrel, leading to applicator failure and/or

possible dangerous conditions that could re-

sult in property damage and personnel injury.

C A U T I O N

!