Ransburg, Vector r series classic applicators - maintenance – Ransburg Vector R Series Classic 79520 R90 Waterborne User Manual

Page 43

Vector R Series Classic Applicators - Maintenance

39

Ransburg

AH-06-02.12

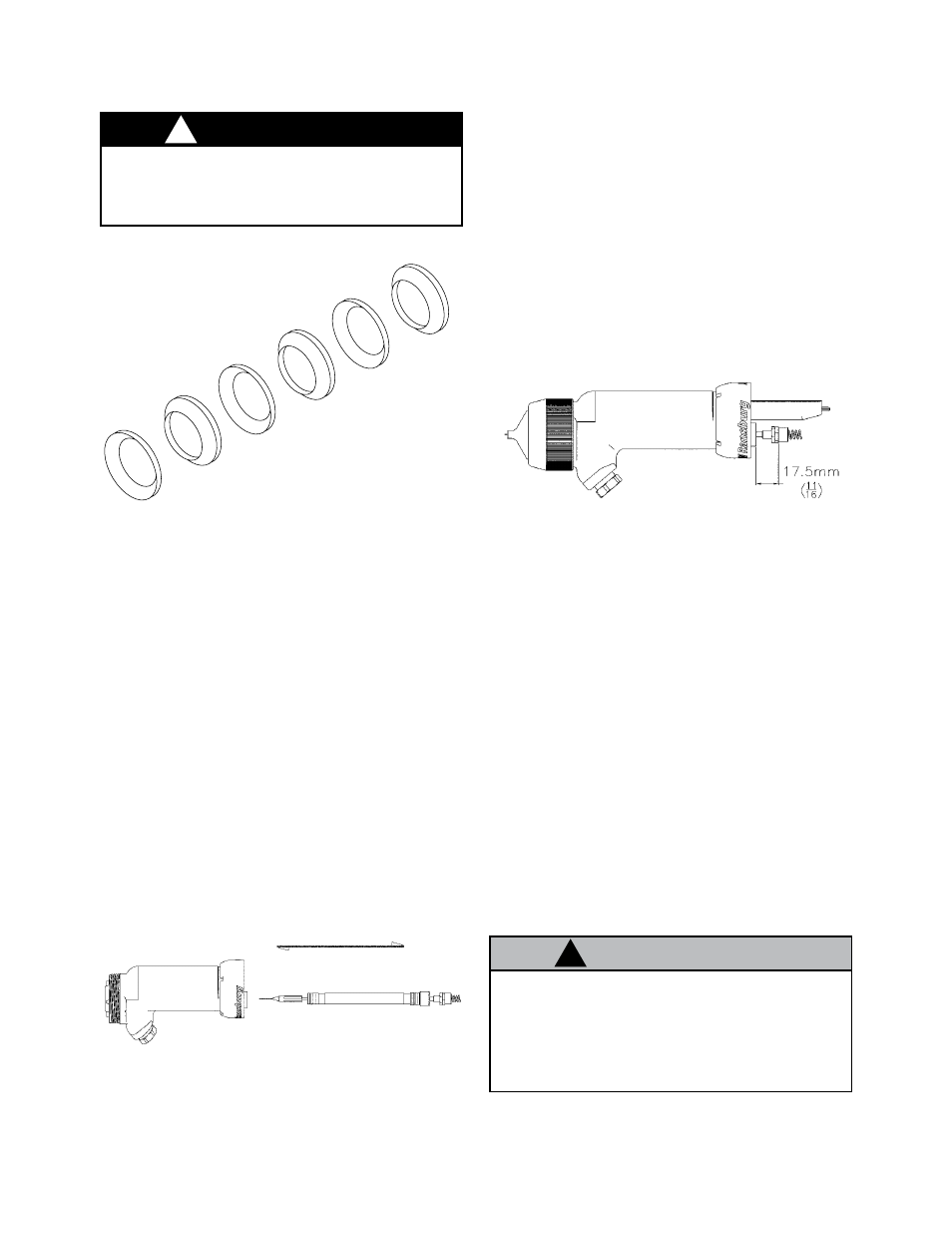

All six (6) spring washers

MUST be re-

placed alternately as shown in Figure 17,

or the applicator will malfunction.

W A R N I N G

!

Figure 17: Spring Washer Assembly Sequence

12. Place the packing nut (large bore first) on the

rear needle shaft section.

13. Screw the trigger adjustment nut onto the rear

needle shaft section with the hexagon rearward

and the spring retainer with the hexagon forward.

Do not lock the hexagon nuts in place.

14. Install the needle shaft sub-assembly into the

packing chamber from the rear of the barrel with

the needle/electrode forward.

15. Push the needle shaft sub-assembly forward

until the packing nut will engage its mating thread

in the barrel and screw it into place by hand, ap-

proximately 3 turns.

Figure 18: Needle Shaft Assembly Into Barrel

16. Pull the needle shaft rearward as far as it

will go.

17. Install the fluid nozzle, air cap, and retaining

nut (refer to "Air Cap" and "Fluid Nozzle" in the

"Maintenance" section).

18. Tighten the packing nut using the spanner

tool on the special multi-purpose wrench until it

bottoms.

Figure 19: Trigger Adjustment Nut Dimensions

19. Push the needle shaft forward until the needle/

electrode seats into the fluid nozzle.

20. Adjust the trigger adjustment nut as far forward

on the needle shaft as possible.

21. Adjust the needle shaft spring retainer until

the rear of the hexagon is 11/16 inch from the

rear surface of the barrel packing chamber (refer

to Figure 19).

22. Hold the spring retainer in place and screw the

front trigger adjustment nut rearward until contact

is made. Use two 3/8" open-end wrenches to

tighten and lock the adjustment nuts in place on

the needle shaft.

DO NOT overtighten the hexagon adjust-

ment nuts or damage may occur to the plas-

tic threads or the needle shaft may break.

Finger tight is typically sufficient. (Maximum

torque of 18-24 in•oz).

C A U T I O N

!