Ransburg, C c w – Ransburg Vector R Series Classic 79520 R90 Waterborne User Manual

Page 40

Vector R Series Classic Applicators - Maintenance

36

Ransburg

AH-06-02.12

Use care in removing the retaining ring.

If it is spread too much it could break.

C A U T I O N

!

8. There is no need to remove the retaining ring

or nut from the barrel unless they are damaged.

If they are to be replaced, lift one end of retaining

ring over the captive ridge and spiral it off the

end of the barrel. Then the retaining nut can be

removed.

Disassembly

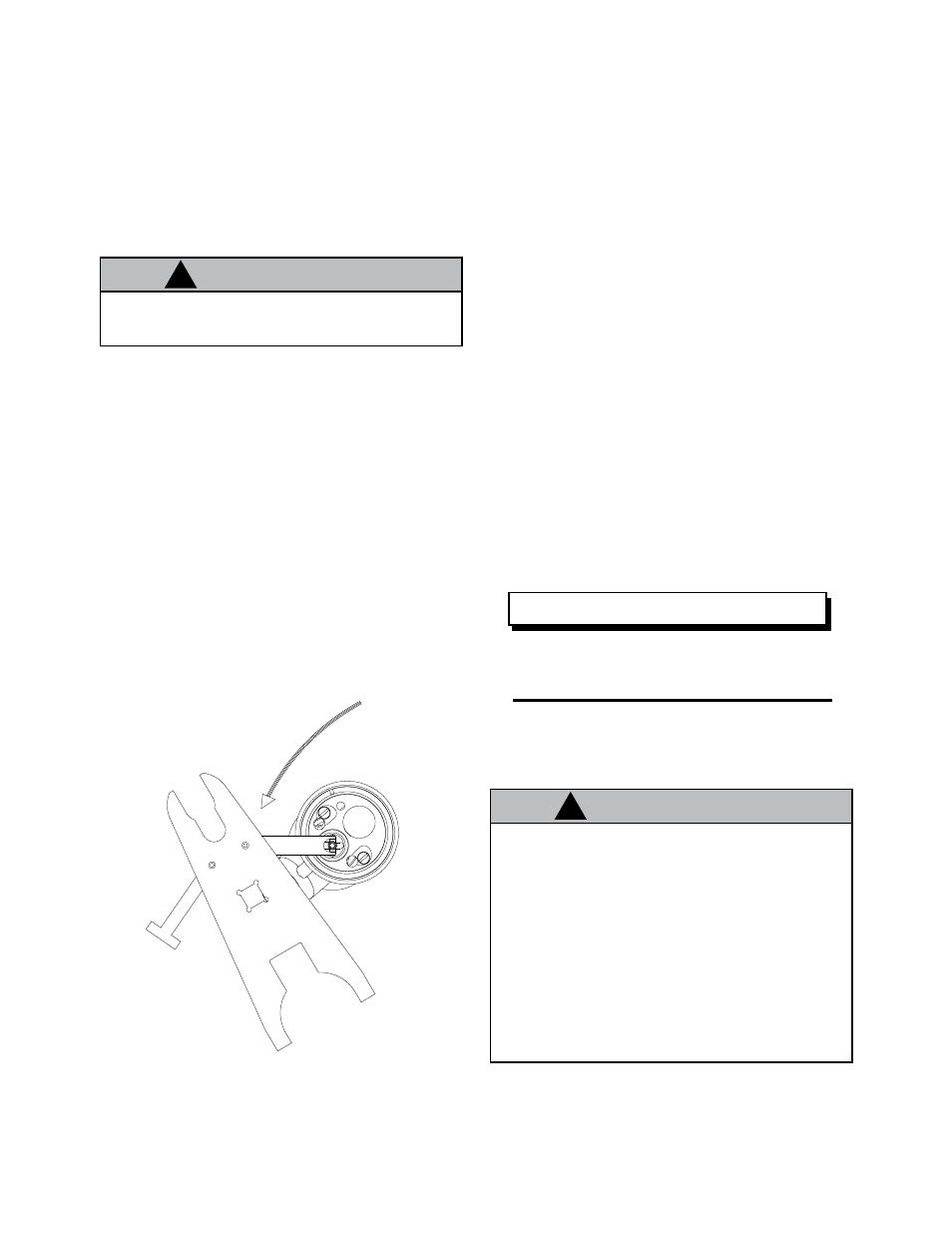

1. Remove the trigger adjustment nut and spring

retainer from the needle shaft using two 3/8"

open-end wrenches.

2. Position the barrel so the front is facing down.

Using the small spanner tool on the special

multi-purpose wrench, unscrew the packing nut

from the rear of the barrel by turning it count-

er-clockwise.

DISASSEMBLY / REASSEMBLY

OF BARREL WITH THE 2K

FLUID NEEDLE PACKINGS

Figure 13: Removal of Needle Shaft

3. Hold the barrel in one hand and with a firm

pull, remove the needle shaft assembly from the

packing chamber of the barrel. The trigger ad-

justment nut can be reinstalled for additional grip.

If the needle shaft will not pull out of the barrel,

use the following procedure.

a. Remove the needle/electrode from the

needle

shaft.

b. Pull the needle shaft from the rear of

the

barrel.

c. Place the barrel on a work bench. Holding

the barrel in one hand, with the front pointing

upward, push a 5/16-inch diameter wooden

or plastic dowel rod, down through the center

bore of the barrel. This should push all of

the packing chamber parts out the rear of

the

barrel.

The six (6) spring washers will come

off the needle shaft assembly at this point.

NOTE

During this operation, be

CAREFUL that

the interior surface of packing chamber is

NOT damaged (marred or scratched)! This

chamber is a seal area and the barrel/appli-

cator assembly will have to be replaced if it

is damaged.

DO NOT lose any of the spring washers!

The gun MUST have all six (6), correctly po-

sitioned, in order to function properly!

C A U T I O N

!

C C W