Mw/s series, General pump, Screw calibration – General Pump MW Repair Manual User Manual

Page 52: Page 52

GENERAL PUMP

A member of the Interpump Group

MW/S SERIES

3. SCREW CALIBRATION

Screws are to be fastened exclusively using a torque wrench.

Description

Exploded View Position

(From Owner’s Manual) Fastening

Ft. Lbs.

Fastening

Nm

Crankcase cover screws M10 x 30

89 (MW32A, MWS36A, MWS40A)

33.2

45

Crankcase cover screws M10 x 30

91 (MWS45A, MWS50A, MWS55A)

33.1

45

Casing Plug, 1/2” x 13

91 (MW32A, MWS36A, MWS40A)

29.5

40

Casing Plug, 1/2” x 13

93 (MWS45A, MWS50A, MWS55A)

29.5

40

Lifting Bracket M16 x 30 Screw

51 (MW32A, MWS36A, MWS40A)

147.5

200

Lifting Bracket M16 x 30 Screw

53 (MWS45A, MWS50A, MWS55A)

147.5

200

Reducer cover screw M10x40

81 (MW32A, MWS36A, MWS40A)

33.2

45

Reducer cover screw M10x40

83 (MWS45A, MWS50A, MWS55A)

33.2

45

Ring gear stopper screw M10 x 25

76 (MW32A, MWS36A, MWS40A)

33.2

45

Ring gear stopper screw M10 x 25

78 (MWS45A, MWS50A, MWS55A)

33.2

45

Reducer case screw M10x40

81 (MW32A, MWS36A, MWS40A)

33.2

45

Reducer case screw M10x40

83 (MWS45A, MWS50A, MWS55A)

33.2

45

Upper and lower cover screw M6x14

60 (MW32A, MWS36A, MWS40A)

7.4

10

Upper and lower cover screw M6x14

62 (MWS45A, MWS50A, MWS55A)

7.4

10

Bearing cover screw m10x30

89 (MW32A, MWS36A, MWS40A)

33.2

45

Bearing cover screw m10x30

9 (MWS45A, MWS50A, MWS55A)

33.2

45

Connecting rod screw M10x1.5x80

53 (MW32A, MWS36A, MWS40A)

47.9*

65*

Connecting rod screw M10x1.5x80

55 (MWS45A, MWS50A, MWS55A)

47.9*

65*

Plunger guide screw M10x35

48 (MW32A, MWS36A, MWS40A)

44.3

60

Plunger guide screw M10x35

50 (MWS45A, MWS50A, MWS55A)

44.3

60

Plunger guide screw M10x140

30 (MW32A, MWS36A, MWS40A)

29.5

40

Plunger guide screw M10x140

18 (MWS45A, MWS50A, MWS55A)

29.5

40

Valve Cover Screw M16 x 55 (MW32A, MWS36A, MWS40A)

26

245.6

333

Valve Cover Screw M16 x 45 (MWS45A, MWS50A, MWS55A)

19

245.6

333

Head plug 1/4” (MWS45A, MWS50A, MWS55A)

4

29.5

40

Head plug 1/4”x13

14 (MW32A, MWS36A, MWS40A)

29.5

40

Head plug 1/4”x13

21 (MWS45A, MWS50A, MWS55A)

29.5

40

Head screw M16x180

28

245.6**

333**

Head screw M16x150

43

245.6**

333**

Valve opening device

2

29.5

40

* Achieve coupling torque tightening screws at the same time.

** Tightening sequence always cross-wise starting from the 4 internal screws then the 4

external screws (see fig. 131).

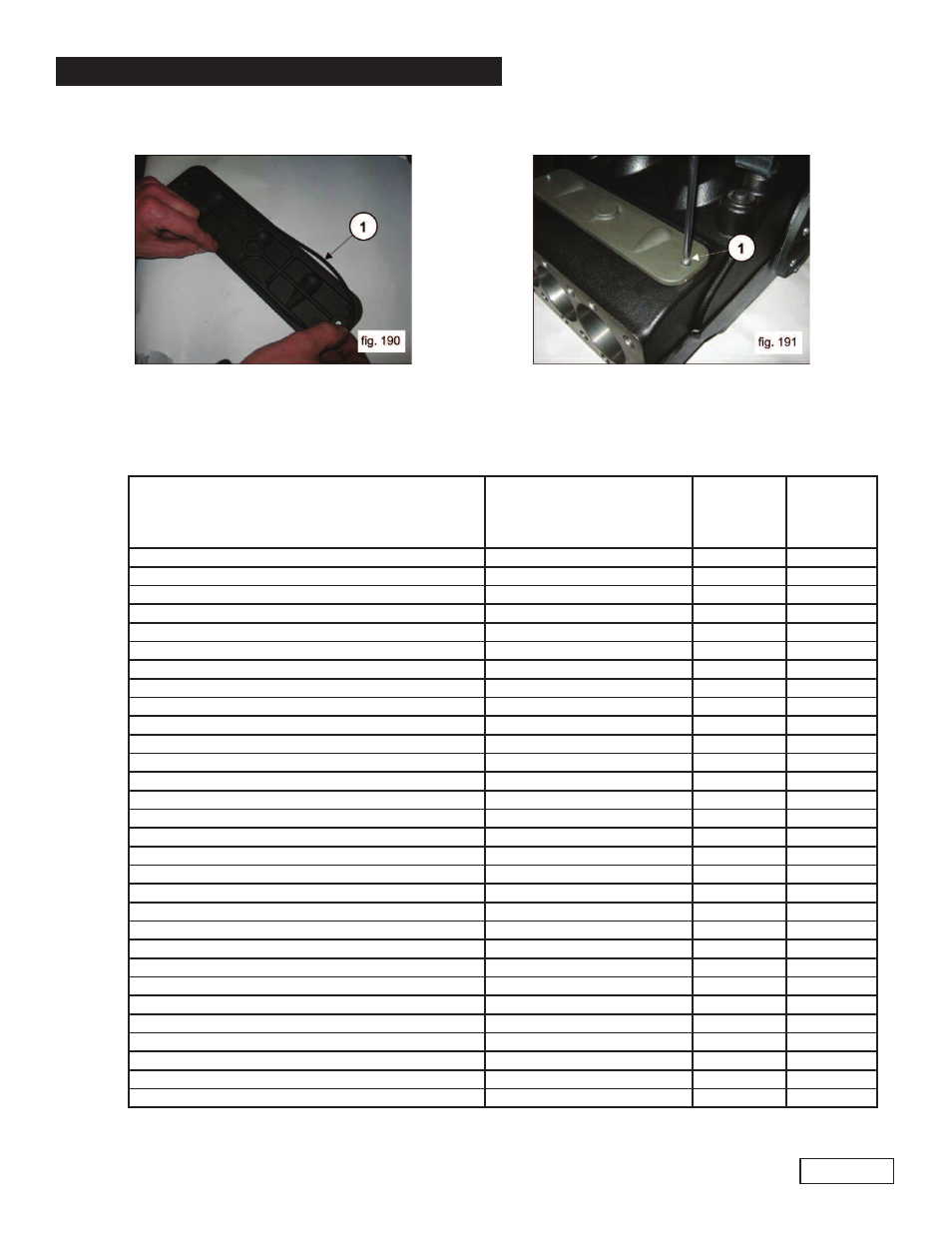

Insert the O-ring on the inspection covers (1, fig. 190) and assemble the covers with the use of 2+2

M6 x 14 screws (1, fig. 191).

Page 52

Calibrate the screws with a torque wrench as indicated in paragraph 3, “Screw Tightening Calibration”.

Ref 300791 Rev.C

11-12