Mw/s series – General Pump MW Repair Manual User Manual

Page 45

GENERAL PUMP

A member of the Interpump Group

MW/S SERIES

Apply the 1/2” plugs on the lower part of the head with relative washers. Proceed with calibration of the 1/2”

plugs with a torque wrench as indicated in paragraph 3 “Screw Tightening Calibration”.

Apply the 1/4” plugs on the front of the head with relative O-rings. Proceed with calibration of the 1/4” plugs

with a torque wrench as indicated in paragraph 3 “Screw Tightening Calibration”.

2.2.5 Dismantling the Plunger Unit - Supports - Seals

The plunger unit requires preventive checks as indicated in the preventive maintenance table in the Owner’s

Manual. Maintenance is limited to visual inspection of any drainage from the hole present on the lower

inspection cover. If abnormalities / variations on the outlet pressure gauge or dripping from the drainage hole

circuit are detected, the seal packings will have to be checked and replaced.

To access the plunger unit, unscrew the M18 x 180 screws (for MW32A, MWS36A and MWS40A) or M16 x

150 screws (for MWS45A, MWS50A and MWS55A) and remove the head.

Remove the head taking care to avoid hitting the plungers.

Page 45

Tighten the 8 M16 x 180 screws starting cross-wise from the 4 inner screws, then

continue with the 4 outer screws, always tightening cross-wise.

Calibrate the M16 x 45 suction and outlet cover screws with a torque wrench as indicated in paragraph 3

“screw Tightening Calibration”.

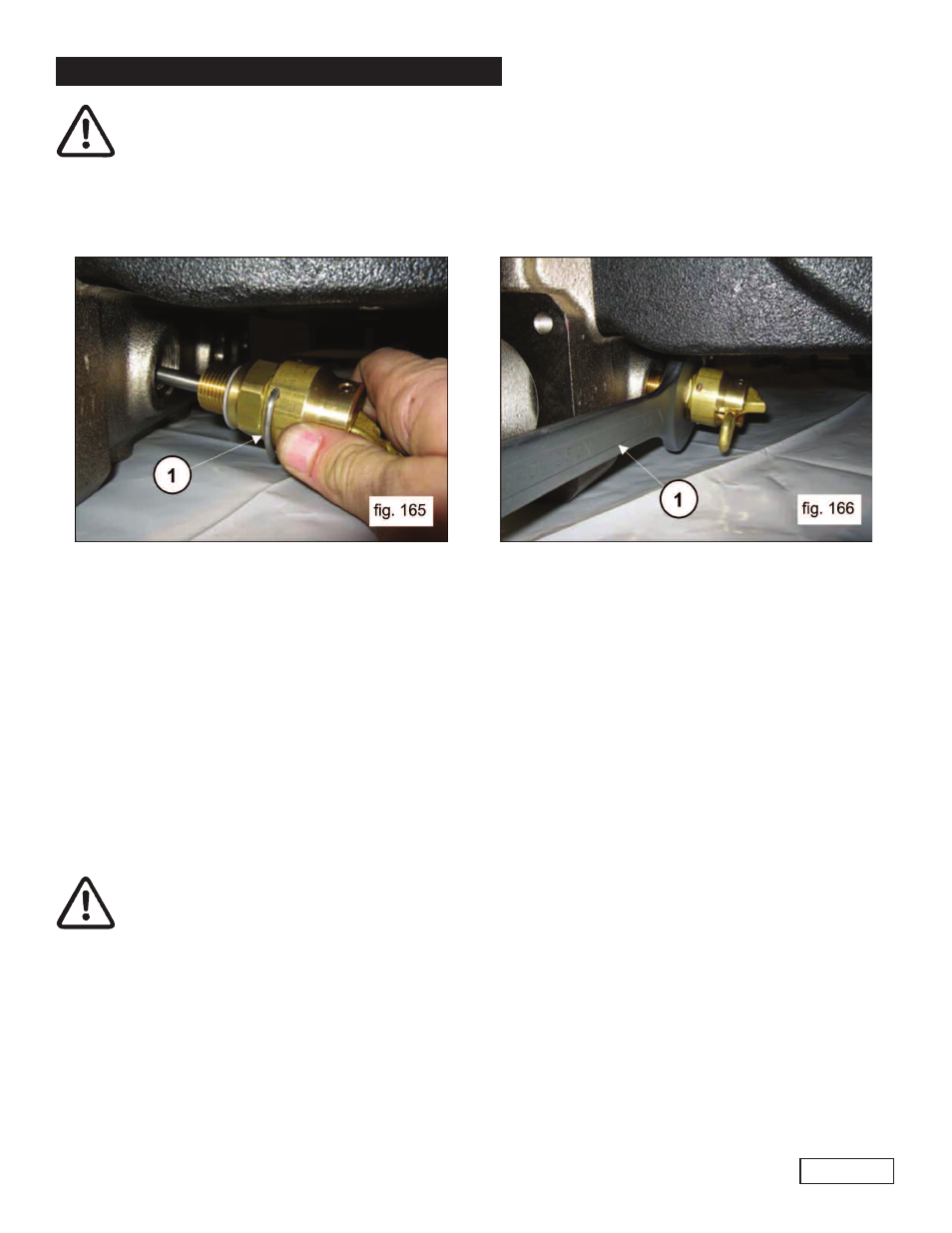

Apply the valve opening devices (1, fig. 165) and screw them in with the use of a 30 mm spanner (1, fig. 166).

Ref 300791 Rev.C

11-12