Teledyne 9110AH - Nitrogen oxides analyzer User Manual

Page 120

TELEDYNE Model 9110AH NO

X

Analyzer Operator Manual, 01620, Rev. F

9-4

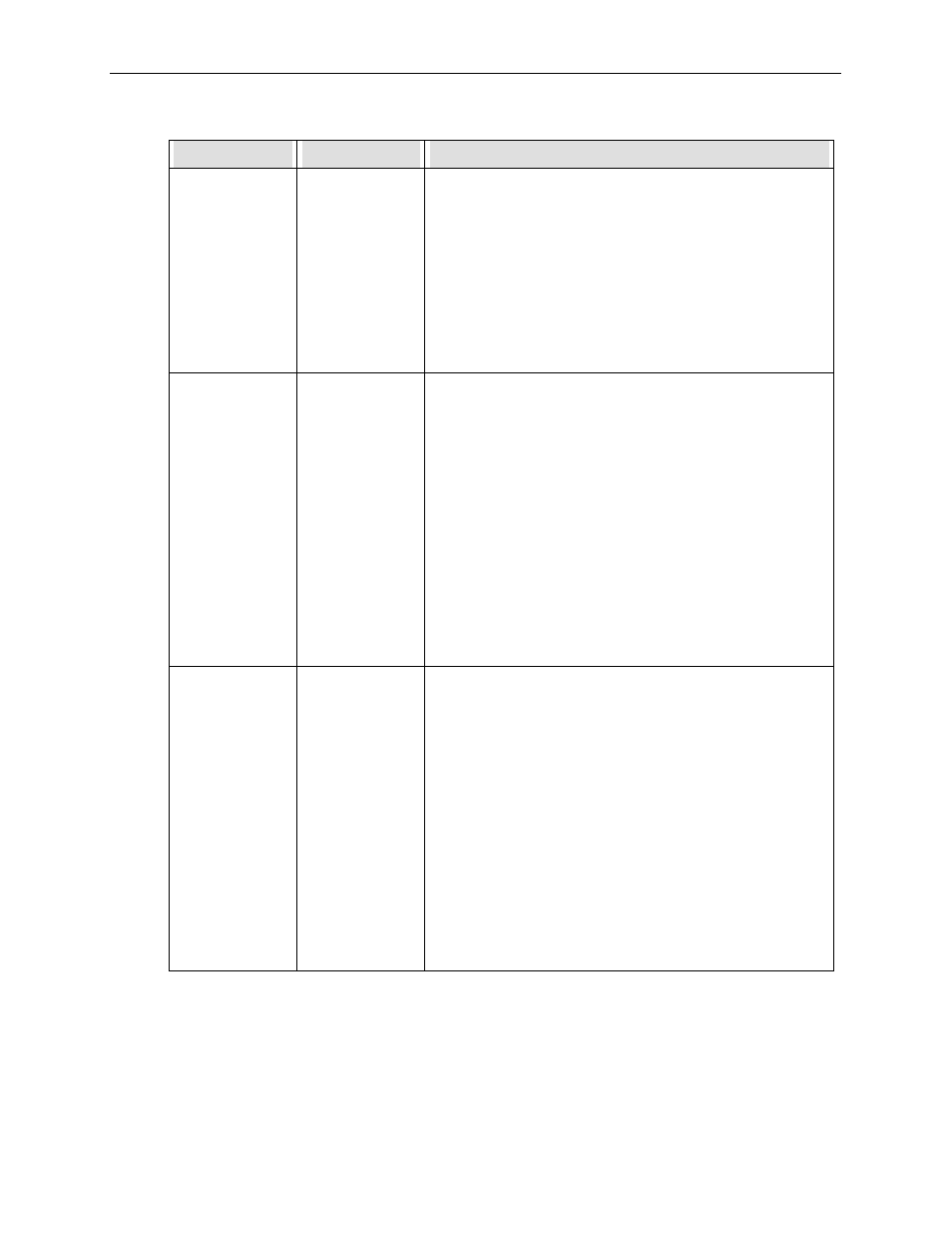

Table 9-1: Test Functions

Test Function

Factory Set-Up

Comment

RANGE

500 PPM

This is the Range of the instrument. In single range mode (standard

configuration) all 3 outputs have the same range. If NO

x

range-2 is

enabled there will be an indication of the range for this output.

Auto range option allows 2 different ranges for instrument output, and

will automatically switch all outputs to the other range dynamically as

concentration values require. The TEST values will show the range

the instrument is currently operating in, and will dynamically display

the alternate range as the range changes occur.

Independent range option allows different ranges for each output.

When enabled, there will be 3 range values displayed. If NO

x

range-2

is enabled there will be an indication of the range for this output

making a total of 4 range indications.

STABIL

Check value in

Final Test Values

Table 2-1

The instrument noise is determined by computing the standard

deviation of the last 10 minutes of data. It is computed using NO

x

channel data when in the NO/NO

x

switching mode or NO

x

only mode.

When in the NO only mode it uses the NO data. The noise value only

becomes meaningful if sampling a constant concentration for more

than 10 minutes. The noise value should be compared to the value

observed in the factory check-out.

Faults that cause high noise values are:

1. Gas leaks

2. Light leak

3.

Faulty HVPS

4.

Defective Preamp board

5.

Outgassing Moly converter

6.

PMT recently exposed to room light

7.

Dirty/contaminated reaction cell

8. Mis-calibrated (slope - offset outside of limits)

SAMPLE FLW

290 cc/min 30

This is the instrument flow. It is computed using the up stream and

down stream pressures across the sample and bypass flow orifices.

This method can give a false flow indication if the orifice is plugged

and the sample pump is creating a pressure drop. It should be taken

into account when diagnosing instrument faults.

- A rTeledyned method of determining if the orifice is plugged is to

disconnect the sample, bypass or ozone tubes upstream of their

respective locations, then briefly put your finger over the fitting. You

should feel the vacuum build up. The bypass flow should be 250

cc/min, the ozone 250 cc/min, and sample flow of 50 cc/min.

- Another reliable method is to attach a rotameter or soap bubble

flowmeter to the fittings to measure the flow.

Flow rate will change a few cc/min due to changes in ambient air

pressure such as cycling of air conditioning, or passing weather

fronts. Changing altitude changes the ambient air pressure and

therefore the sample flowrate. This effect is about 15-20 cc/min per

1000 feet of altitude change. If required, the output of the instrument

can be compensated for pressure. See Section 5.3.9,

Table 9-5

.

(table continued)