System start-up prechecks, Damper adjustment – Detroit Radiant Products Company HLV Series User Manual

Page 44

44

HLV

Series

4.0

Operation

•

System Start-Up and Damper Adjustment

System Start-Up Prechecks

• Confirm all gas piping, electrical wiring, etc. are properly installed.

• Preset the primary and secondary damper(s) to half-open.

• If applicable, unassisted combustion air ducts must be installed before start-up.

• If applicable, fan assisted outside combustion air ducts must not be connected to burner control box

upon initial start-up.

Damper Adjustment

1

The system must run for 20 minutes in

high fire mode before setting the dampers. Confirm all

operational indicator lights (located on the burner control box) are on.

2

All system dampers are preset to half-open. If a burner fails to stay lit or does not light, the damper

serving that burner must be adjusted until the burner is continually lit throughout the initial 20 minute

start-up.

3

Using a manometer with an adequate range, measure the vacuum pressure (Figure 4.2) at the

burner furthest from the vacuum pump. Adjust the primary damper at the pump until the manometer

reaches the specified reading shown in Chart 4.2.

NOTE: If proper box static pressure cannot be achieved, it may be necessary to remove one, two or

all three baffle sections (P. 27). Consult factory following basic troubleshooting (i.e. proper pump

rotation, check for blockages, baffle installed correctly, control box covers are secured, etc.).

Chart 4.2 •

Burner Box Pressure Setpoints

Burner Box Input (BTU/h)

Box Pressure (inches W.C.)

40,000 to 60,000

-0.51 +/- .01

75,000 to 110,000

-0.19 +/- .01

120,000 to 180,000

-0.22 +/- .01

200,000

-0.19 +/- .01

The system must operate in high fire for 20 minutes before adjusting the dampers.

Each system damper must be adjusted to the box pressure setpoints listed above.

4

If secondary dampers are installed in the system, connect manometer to each applicable burner

and set applicable secondary damper to the specified reading (Chart 4.2).

5

Once each damper has been adjusted, burner pressures must be checked to confirm initial

setpoints did not change. Readjust dampers as necessary in the same order. Lock dampers in place.

6

If fan assisted outside air ducts are used, connect to control box after initial start-up is complete;

Adjust supply dampers (supplied with powered air inlet P/N: V-PAI - sold separately) until the

required pressures are achieved.

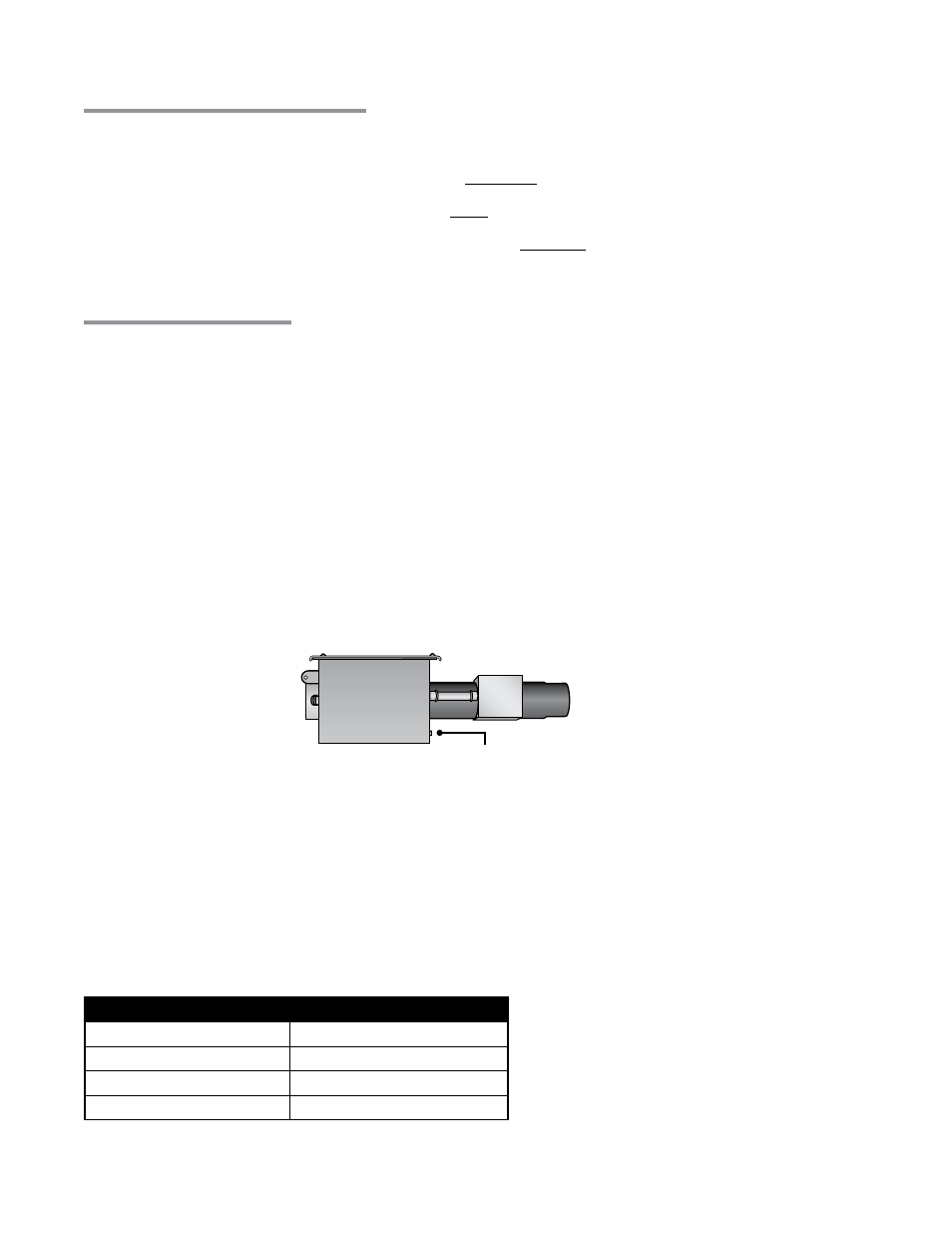

Figure 4.2 •

Burner Control Box Vacuum Port

Vacuum Port

NOTE: Remove the plug on

vacuum port to measure box

pressure. Ensure burner box

lid is tightened securely.