Design for condensing systems – Detroit Radiant Products Company HLV Series User Manual

Page 12

12

HLV

Series

2.0

Design

•

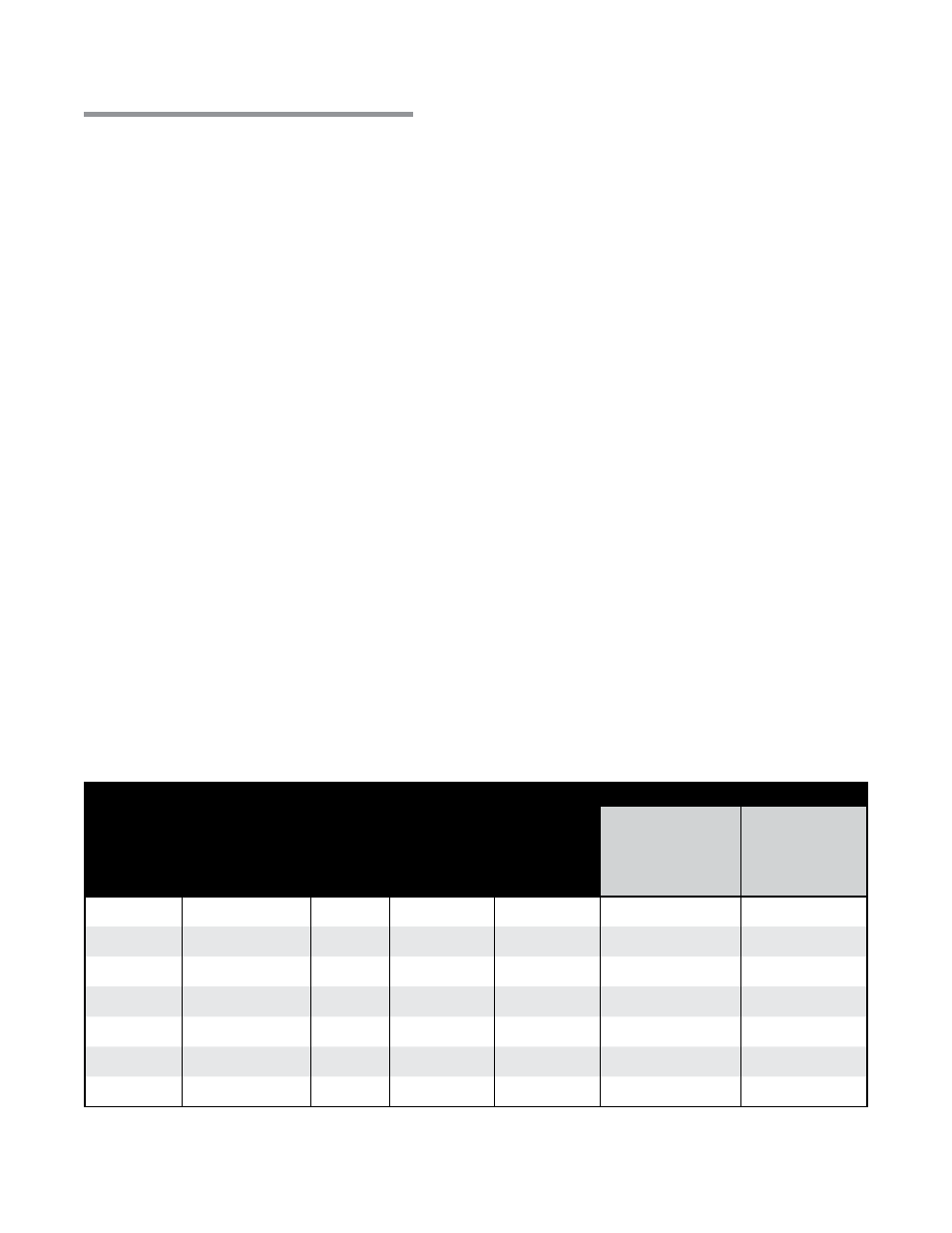

Design for Condensing Systems

Simulated In-Line Systems*

HLV Burner

Model

Minimum

Distance from

Burner to First

Elbow or

Intersection (Ft.)

Calculated

Minimum

Run (Ft.)**

Calculated

Starting Point

of Condensing

Run (Ft.)

Calculated

Maximum Run

(Including

Condensing

Pipe) (Ft.)

Maximum Actual

Distance Between

Tie-Ins for Simulated

In-Line Systems (Ft.)

Starting Point

(after last tie-in)

for Condensing for

Simulated In-Line

Systems (Ft.).

40, 50, 60

10

30

60

175

50

40

75, 80

10

35

65

200

55

50

90, 100

10

40

70

200

60

50

110, 120, 125

10

45

75

225

65

60

140, 150

15

50

80

225

70

60

170, 175, 180

15

55

85

250

75

70

200

20

60

90

250

80

70

Design for Condensing Systems

Chart 2.2 •

Design Parameters for Condensing Systems

(refer to page 14 for definitions).

System tube lengths are determined by the gas input (BTU/H) of each burner. Chart 2.2 below

indicates system design parameters for each burner model used in each system. When calculating

tube lengths, do not add in elbow and tee fittings as they have been accounted for.

Designing a condensing system can be fairly straightforward given the following steps are read carefully.

In addition to these steps, an understanding of the design definitions is critical. Refer to p.14 for these

terms and illustrations.

1

Begin by designing a tentative layout without regard to design parameters. Use this approach to

place each burner and the vacuum pump where most desired (refer to Figures 2.4 - 2.10 for typical

system layouts).

2

Once a tentative layout has been established, confirm that each run in the system meets the criteria

for ‘Calculated Minimum Run’. ‘Calculated Minimum Run’ is determined by adding the total

‘Single Flow’ plus one-half of the ‘Common Flow’.

• If the system does not meet the ‘Calculated Minimum Run’, length must be added to the run until

all burners meet the design parameters.

3

Refer to Chart 2.2 to determine the ‘Calculated Starting Point of Condensing Run’ for each individual

burner run. All elbows and intersections that fall within the condensing section of run, must also

utilize condensing pipe. If there are no runs long enough to utilize condensing pipe, then the system

is regarded as a non-condensing system.

IN-LINE SYSTEMS: If the system requires the simulation of in-line burners, all tie-in burners

(Figure 2.1) must be located no less than the ‘Minimum Distance from Burner to First Elbow or

Intersection’; also reference ‘Maximum Actual Distance Between Tie-Ins for Simulated In-Line

Systems’ to ensure the tie-in distance is

not exceeded. Reference Chart 2.2 to determine the

‘Starting Point for Condensing for Simulated In-Line Systems’.

When using an in-line approach,

skip to step 5.

NOTE: Contact the factory for approval when system design exceeds the guidelines set forth in the

table above.

* Actual run; not calculated.

**

Be sure to account for runs where Tandem Tee Set (V-TTS) are

used in the system.