Damper application – Detroit Radiant Products Company HLV Series User Manual

Page 19

19

HLV

Series

2.0

Design • Damper Application

Damper Application

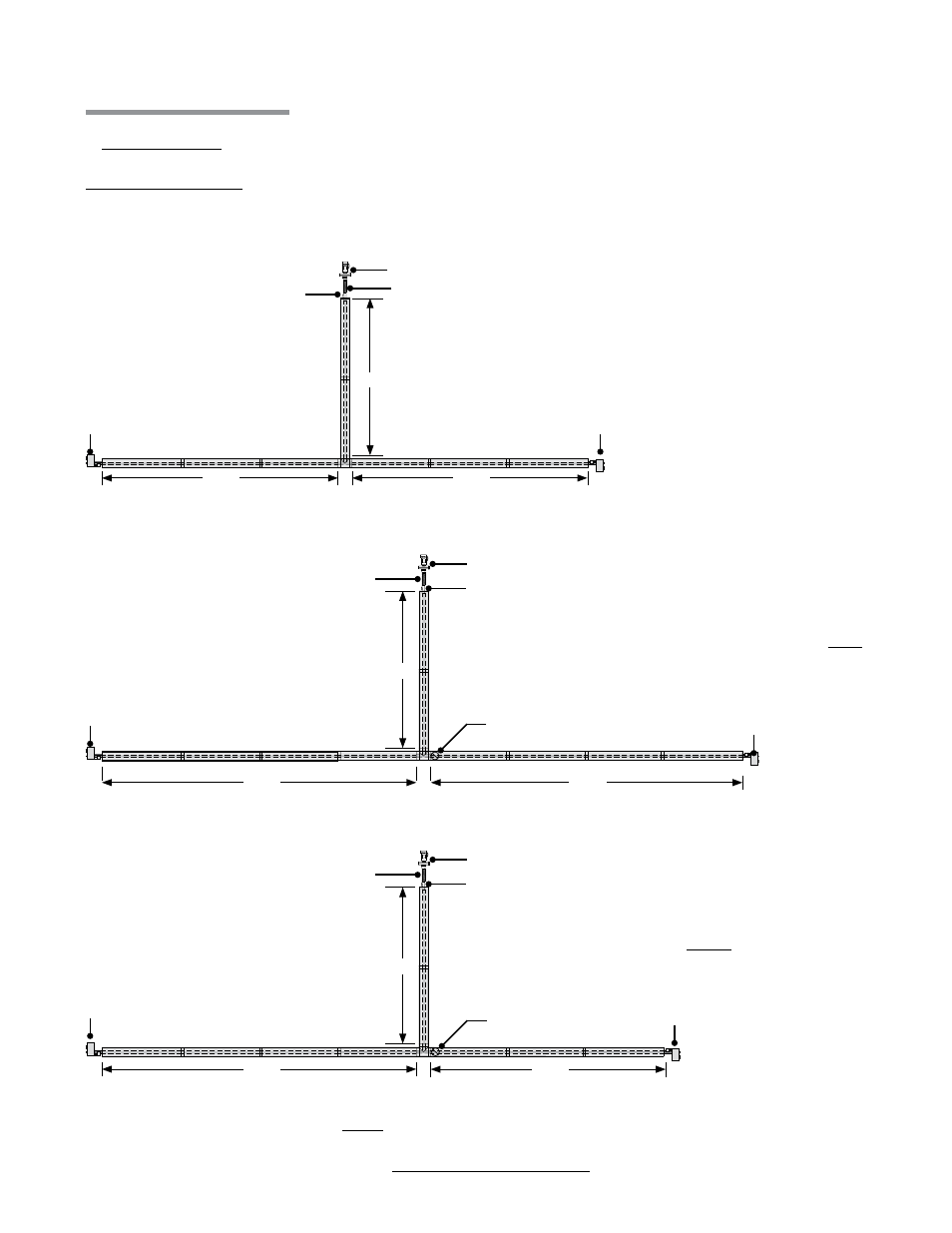

Figure 2.12 •

Damper Placement

•

Equal Burner Inputs and Equal Tube Runs*

Figure 2.14 •

Damper Placement

•

Equal Burner Inputs and Variable Tube Runs*

A primary damper is provided with every system which is placed before the vacuum pump.

Systems with variances in burner gas inputs and/or radiant tube runs will require the placement of

secondary dampers* to balance the system’s exhaust flow.

NOTE: A maximum of six dampers are

allowed in a system. Refer to Figures 2.12 - 2.14 for examples of damper placement.

Figure 2.13 •

Damper Placement

•

Variable Burner Inputs and Equal Tube Runs*

This system is comprised of two 75,000

BTU/H burners with equal lengths of radiant

tube running to the vacuum pump. Only the

primary damper is required in this type of

system.

HLV-75

Vacuum Pump

20 ft.

30 ft.

Primary Damper

Isolation Boot

30 ft.

HLV-75

40 ft.

HLV-100

HLV-75

Vacuum Pump

20 ft.

Primary Damper

Isolation Boot

40 ft.

Secondary Damper

40 ft.

30 ft.

Secondary Damper

Vacuum Pump

20 ft.

Primary Damper

Isolation Boot

HLV-75

HLV-75

This system is comprised of two 75,000

BTU/H burners with unequal lengths of tube

run to the vacuum pump. The primary

damper is required at the vacuum pump and

a secondary damper is required prior to the

tee serving the shorter tube run.

A 75,000 BTU/H and a 100,000 BTU/H

burner with equal lengths of radiant tube

running to the vacuum pump make up this

system. The primary damper is required at

the vacuum pump and a secondary damper

is required prior to the tee serving the lower

BTU/H burner.

* In the event where a 40,000, 50,000 or 60,000 BTU/H burner shares a common run with a 75,000

BTU/H burner or higher, each run

must be dampered prior to each tee. This allows ease in balancing

the higher box pressure set points present on HLV-40, HLV-50 and HLV-60 burners. A sample of this

design scenario can be viewed online at www.reverberray.com/cad.