0 installation, Warning, Pre-installation – Detroit Radiant Products Company HLV Series User Manual

Page 20

20

HLV

Series

3.0

Installation

Pre-Installation

• Verify that the heater’s gas type and voltage (as listed on burner rating label) match that of the application.

• Verify that all heater contents have been received by checking them against the packing list.

• Verify that the vacuum pump is adequate for the BTU/H input of the system (as listed on rating label).

• Identify the 10 ft. Alum-Ti combustion chamber(s) and ensure one exists per burner. These will be

installed as the first tube section (welded seam down) immediately following each burner box.

• Following an engineered design layout, determine the location for the system’s suspension points in

relation to the building structure. Ensure that the installation will conform to the design requirements

listed in Section 1.0 and clearance to combustibles (Chart 1.2, p.9) will be maintained.

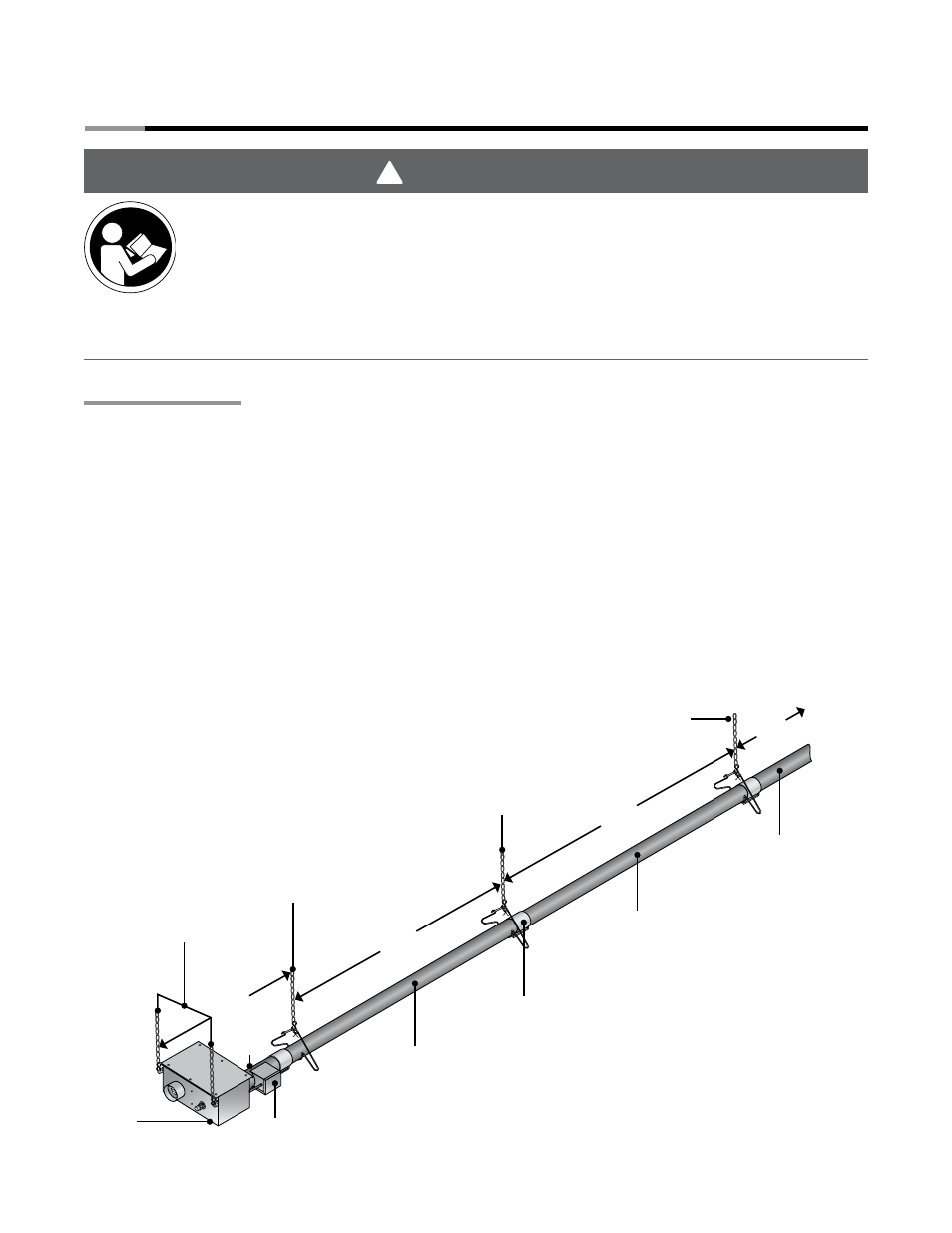

• Each system is supplied with the necessary chain sets and tube hangers used for suspending the

burner(s), radiant tubing, condensing pipe (if applicable) and reflectors. See Figure 3.1.

NOTE: Mounting Chains must hang perpendicular to the system. The use of 12 gauge, #1 double-loop

chain (P/N: THCS) is recommended for hanging the system.

3.0

Installation • Pre-Installation

Figure 3.1 •

Heater Suspension Points

WARNING

!

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, serious injury or death. Read and understand the installation, operation and

maintenance instructions thoroughly before installing or servicing this equipment. Only

trained, qualified gas installation and service personnel may install or service this equipment.

Not for residential use! Do not use this heater in the home, sleeping quarters, attached

garages, etc.

Installation of a commercial tube heater system in residential indoor

spaces may result in property damage, serious injury or death.

NOTE: A sticker identifying the combustion chamber(s)

is located on the swaged end of the tube(s).

10 ft. Titanium Treated (Alum-Ti)

Primary Combustion Chamber

Radiant Emitter Tube

NOTE: 150-200 MBH burners with the

hot-rolled steel option utilize an aluminized

steel secondary combustion chamber.

2’ 4”

8’ 10

”

9’ 8

”

9’ 8

”

Burner

Control Box

Radiant Emitter Tube(s)

Suspension

Point

Burner Control Box

Suspension Points

Suspension Point

Suspension Point

Ignitor/Sensor Box

Stainless Steel Tube Clamp

(170-200 MBH burners only)

16” Burner

Tube