Baffle assembly and placement – Detroit Radiant Products Company HLV Series User Manual

Page 27

27

HLV

Series

3.0

Installation

•

Tube Assembly and Mounting

•

Baffle Assembly and Placement

5

Slide baffle assembly into the section of tubing closest to the vacuum pump that allows insertion of

the entire length of baffle.

NOTE: If baffle assembly cannot be placed in the single run closest to the

pump, install in the tube upstream of the single run to the pump. Figure 3.13.

6

Rotate baffle assembly so that it is in the

vertical position. However, if the baffle assembly

intersects with a tee or cross rotate so that it is in the

horizontal position. Figure 3.13.

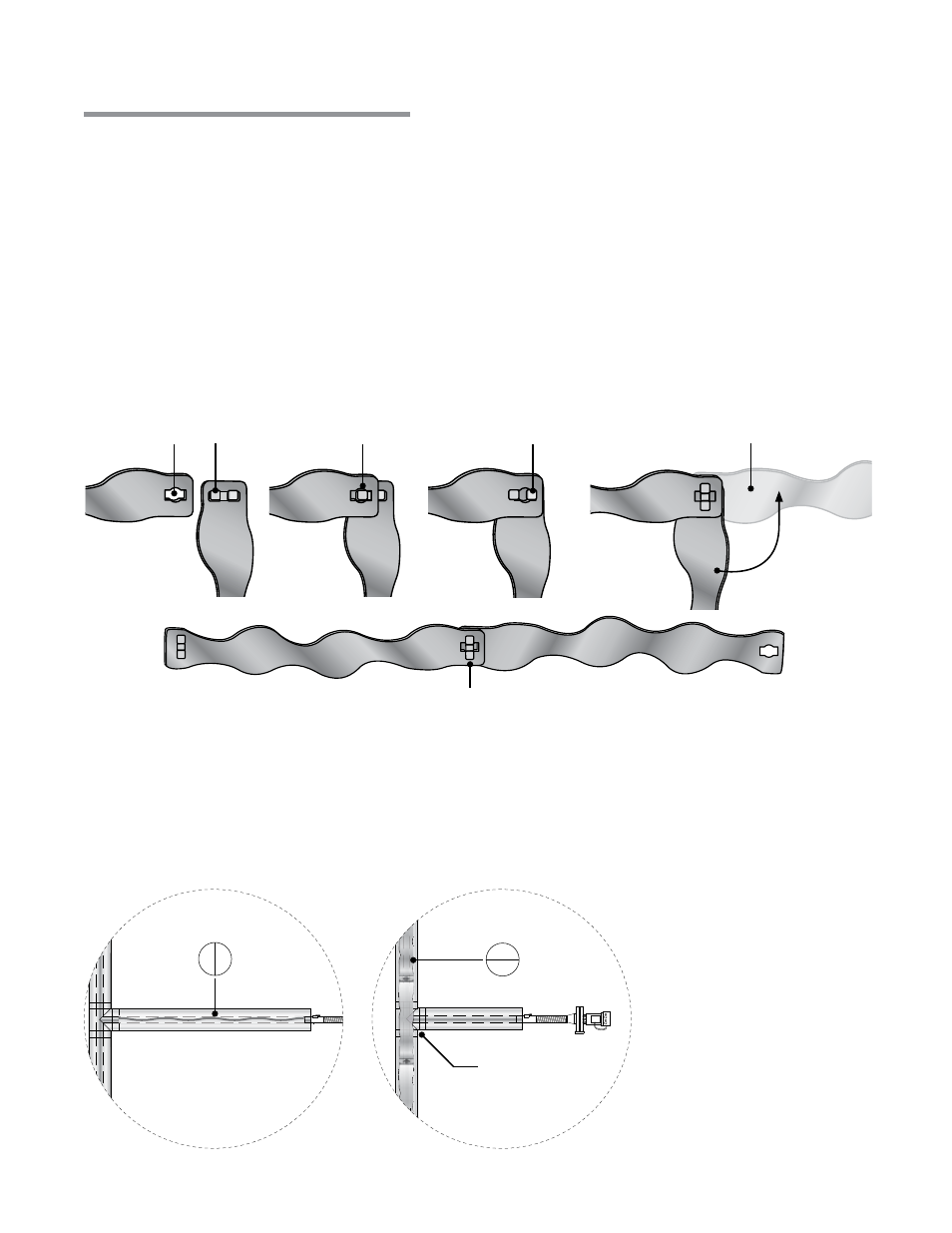

Figure 3.12

•

Assembling the Baffles

1

Baffle keyhole

Baffle tabs

2

3

Completed connection

All systems include three sections of baffle, having an assembled length of 99 inches.

NOTE: In

some applications it may be necessary to remove one, two or all three baffle sections to achieve

proper static pressure at the burner box (P. 44). Consult factory.

1

Orient the baffle tabs at a 90° angle to the baffle keyhole (Figure 3.12).

2

Insert one baffle tab into keyhole and slide completely to one side until both baffle tabs appear in

the keyhole.

3

Adjust the tabs to the center of the keyhole and rotate the baffle 90 degrees to lock the baffle

sections together.

4

Repeat this process with remaining baffle sections to complete assembly.

NOTE: Baffles may be

inserted into the tube while being assembled.

Baffle Assembly and Placement

Figure 3.13

•

Baffle Placement

Horizontal position

Vertical position

Intersection