Tube assembly and mounting – Detroit Radiant Products Company HLV Series User Manual

Page 23

23

HLV

Series

3.0

Installation

•

Tube Assembly and Mounting

• Hanger Placement

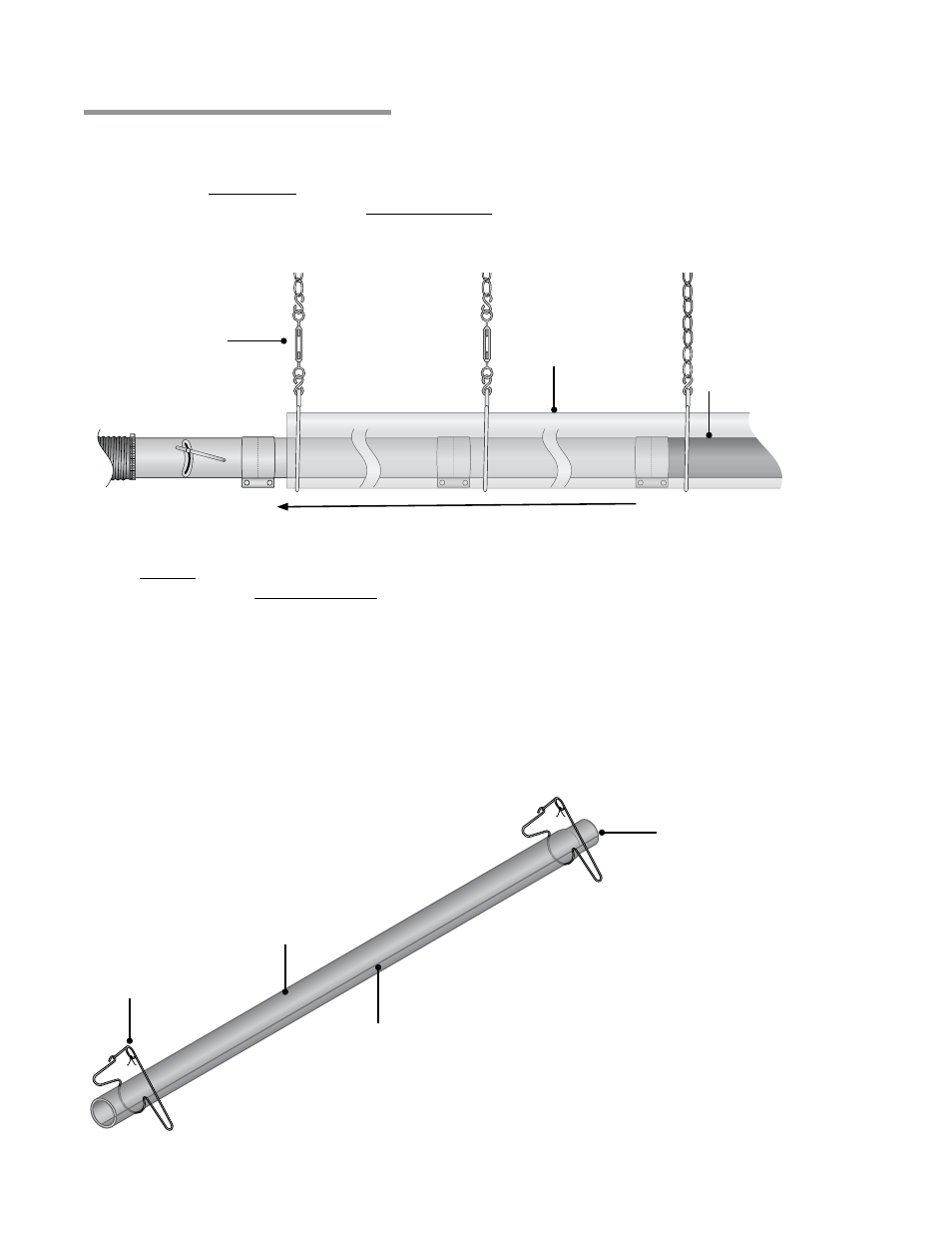

Tube Assembly and Mounting

Tube installation begins at the vacuum pump:

1

If installing a condensing system, slope condensing pipe

upward from the vacuum pump 1/4 in.

per 10 ft. as shown in Figure 3.5. Non-condensing systems are mounted level.

Figure 3.5 •

Condensing Pipe Suspension

2

It is

critical that tube mounting begins with the run having the greatest amount of condensing

pipe. If installing a non-condensing system, begin with the longest run.

NOTE: Baffle installation must be as close to the vacuum pump as possible and in the section of

tubing that allows insertion of the entire length of baffle (refer to page 27 for baffle assembly and

placement instructions).

3

Space two wire hangers approximately 8 ft. to 9 ft. apart to mount the first tube section. Only one

hanger is required for every tube thereafter, spaced approximately 9’-8” apart. Place tubes in

hangers with welded seam facing downward and the swaged end of the tube towards the vacuum

pump (Figure 3.6).

Figure 3.6 •

Tube Hanger Placement

Slope condensing pipe 1/4 in. per every 10 ft.

as it approaches the vacuum pump.

Turnbuckles (P/N: V-TB)

are recommended for all

condensing pipe suspension

points for ease of slope

adjustment.

Standard

Radiant Tubing

Condensing Pipe

Condensing Pipe

All standard radiant

tubing must be

installed level.

Hanger

Welded seam

faces down

Swaged end

(toward pump)

Radiant Tube

Reflector