Detroit Radiant Products Company HLV Series User Manual

Page 24

24

HLV

Series

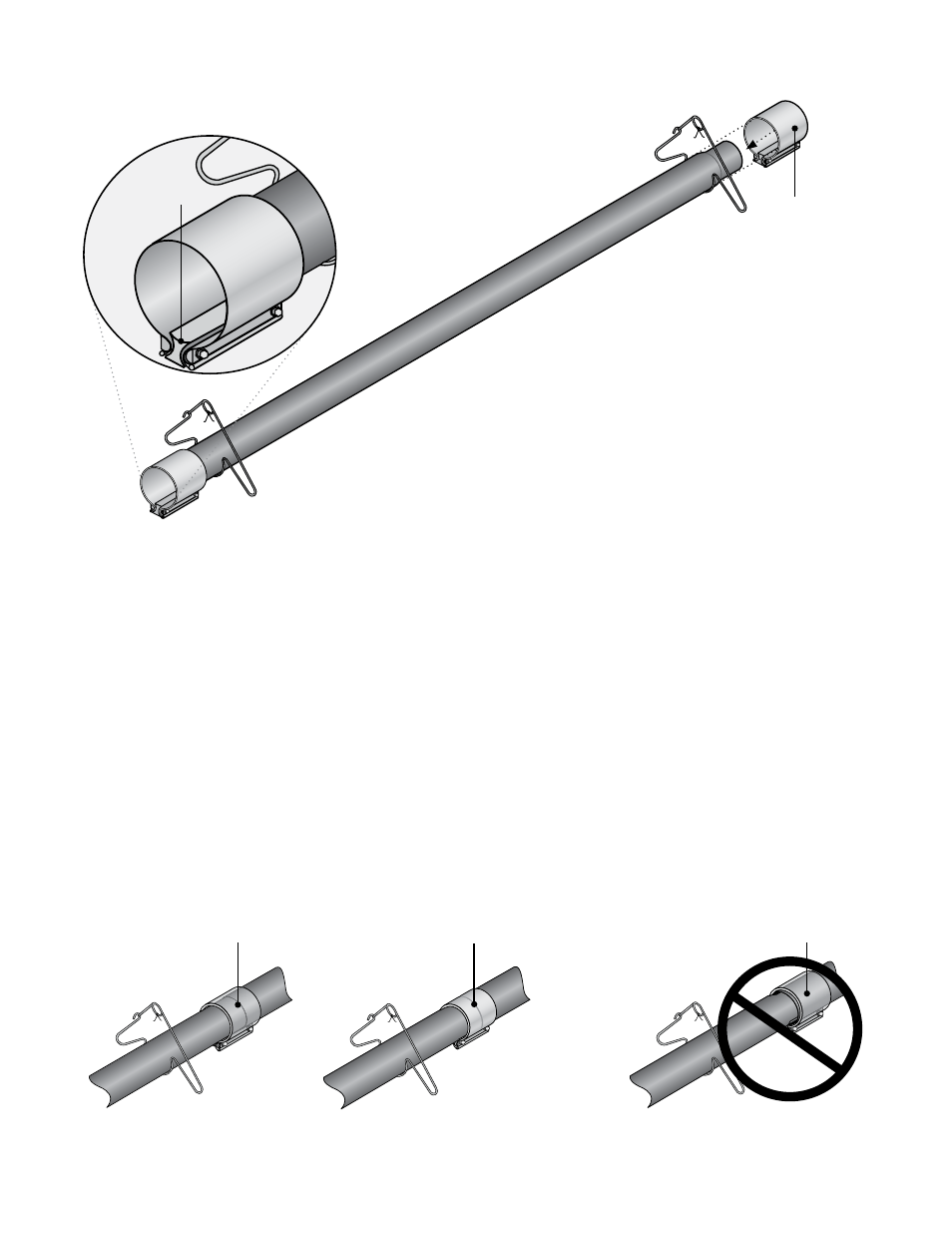

Figure 3.7

•

Attach Tube Clamps

Tube Clamp

IMPORTANT! 170,000 to 200,000 BTU/h models must be

installed with a stainless steel tube clamp (P/N: TP-220) located at

the seam between the primary combustion chamber and the

second tube section downstream of the burner control box.

NOTE: If the tube clamp comes

apart, the spacer

must be

re-assembled with the spacer’s

concave surface facing against

the radiant tube surface.

Concave surface

1

Place tube clamps directly over tube seams (Figure 3.8).

2

Slip-fit the radiant tube sections together until tightly connected (install the swaged end of each tube

towards vacuum pump).

NOTE: If it is difficult to mate the tubes, they may be misaligned.

3

Center tube clamps over the seam where two radiant tube sections connect. If necessary, rotate tube

clamps so they will not interfere with the reflector end caps during expansion and contraction of

the heater.

4

Tighten tube clamp bolts to secure. When proper compression is obtained (40-60 ft.-lbs. torque) the

tube seam will create a visible mark on the tube clamp.

NOTE: Excessive torque may damage the

tube clamp.

Figure 3.8

•

Tube Connections

Tubes fit snuggly together and the

tube clamp is centered over the seam.

Tubes are not fit snuggly

together and the tube clamp is

not centered over the seam.

The tube clamp is tight when the

torque is achieved (normally

when seam becomes visible).

Correct Tube Connection

Incorrect Tube Connection

3.0

Installation

•

Tube Assembly and Mounting

•

Tube Clamps