Burkert Type 8611 User Manual

Page 9

9

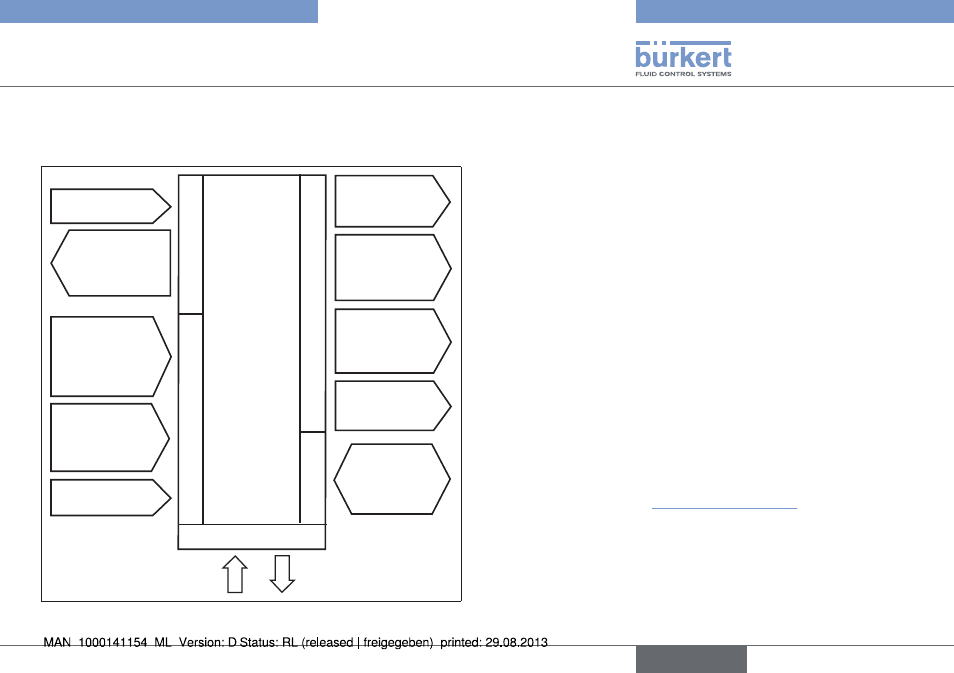

SystemDescription

the process actual value and for controlling the actuating elements.

The diagram below shows the available interfaces of the process

controller.

24 / 5 V DC

electrical power

supply for

sensors

Sensor inputs

4 - 20 mA /

0 - 10 V,

frequency, Pt 100

Supply

24 V DC

Binary input

0-30 V DC

Ext. set-point

value default

or ratio

4 - 20 mA /

0 - 10 V

Analog output

4 - 20 mA /

0 - 10 V

Transistor

outputs

PWM, 2P – T,

3P – T

Process value

output

4 - 20 mA /

0 - 10 V

Binary output

0 / 24 V

(NC / NO)

RS485

option, for

control cabinet

model only

Process

controller

eCONTROL

Typ 8611

Inputs

Interfaces

Supply

Operation

Outputs

Fig. 2: Interfaces of the process controller Type 8611

5.3.

functions

The following control tasks can be executed with the process con-

troller Type 8611 eCONTROL.

• Fixed command control (single-loop control circuit)

• Sequential control (external set-point value)

• Ratio control

• Cascade control

Standard signals (current / voltage) and frequency-analog signals

can optionally be applied or resistance thermometers (Pt 100) can be

connected to the scalable controller inputs.

Outputs for continuous standard signals (current / voltage) or tran-

sistor outputs can be used as controller outputs. Valves or other

switching actuators can be operated via the transistor outputs. One

binary output and up to 2 binary outputs for auxiliary functions are

additionally provided.

5.4.

The various mounting and

installation models

The process controller Type 8611 is available in the following

models (see also chapter “7.1. Assembly models”):

• For installation in a pipeline system

• For attachment to a proportional valve

• For wall assembly or for assembly on a rail

• For installation in a control cabinet

english

Type 8611