Burkert Type 2100 User Manual

Page 12

12

Installation

→

Control function A pressurize the pilot air port 1 with com-

pressed air (5 bar): valve opens.

→

Counter on the flats of the nipple with a suitable open-end

wrench.

→

Place suitable open-end wrench on the hexagon of the actuator.

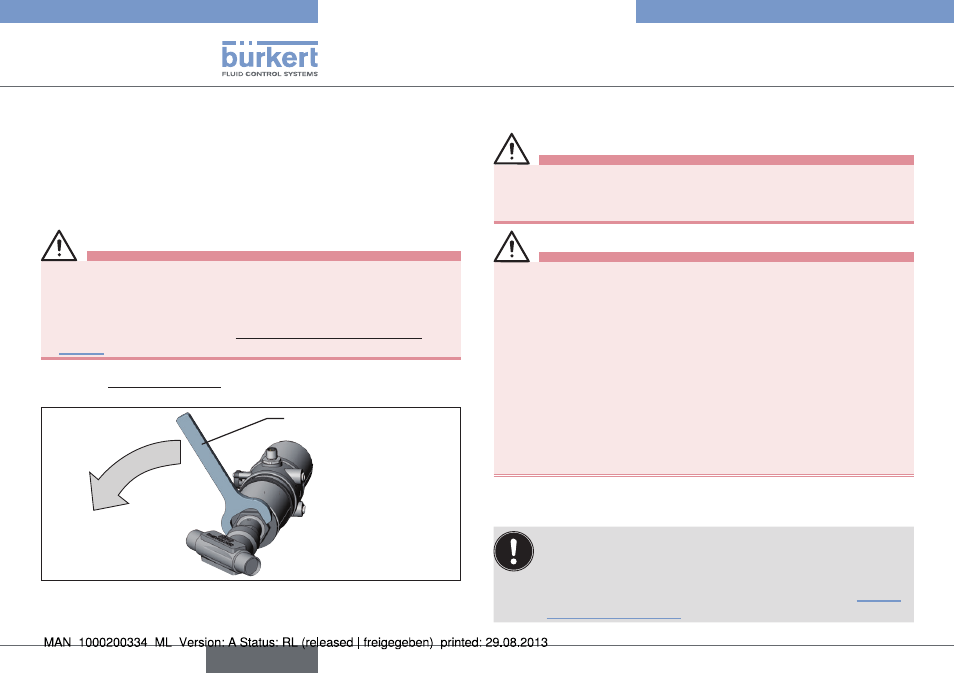

WARNING!

Risk of injury from discharge of medium and pressure.

If the direction of rotation is wrong, the body interface may

become detached.

• Rotate the actuator module in the specified direction only (see

“Fig. 5”).

→

Rotate counter-clockwise (as seen from below) to bring the

actuator module into the required position.

Open-end wrench

Fig. 5:

Rotating with open-end wrench

7.4. Pneumatic connection

DANGER!

Danger – high pressure in the equipment.

• Before loosening the lines and valves, turn off the pressure and

vent the lines.

WARNING!

Risk of injury from unsuitable connection hoses.

Hoses which cannot withstand the pressure and temperature

range may result in hazardous situations.

• Use only hoses which are authorised for the indicated pressure

and temperature range.

• Observe the data sheet specifications from the hose manufacturers.

For control function I – Danger if pilot pressure fails.

For control function I control and resetting occur pneumatically. If

the pressure fails, no defined position is reached.

• To ensure a controlled restart, first pressurize the device with

pilot pressure, then switch on the medium.

7.4.1. Connection of the control medium

If the position of the pilot air ports for installation of the hoses

is unfavorable, these can be aligned steplessly by rotating

the actuator through 360°.

The procedure is described in the chapter entitled “7.3.3.

Rotating the actuator”.

english

Type 2100