Burkert Type 2100 User Manual

Page 10

10

Installation

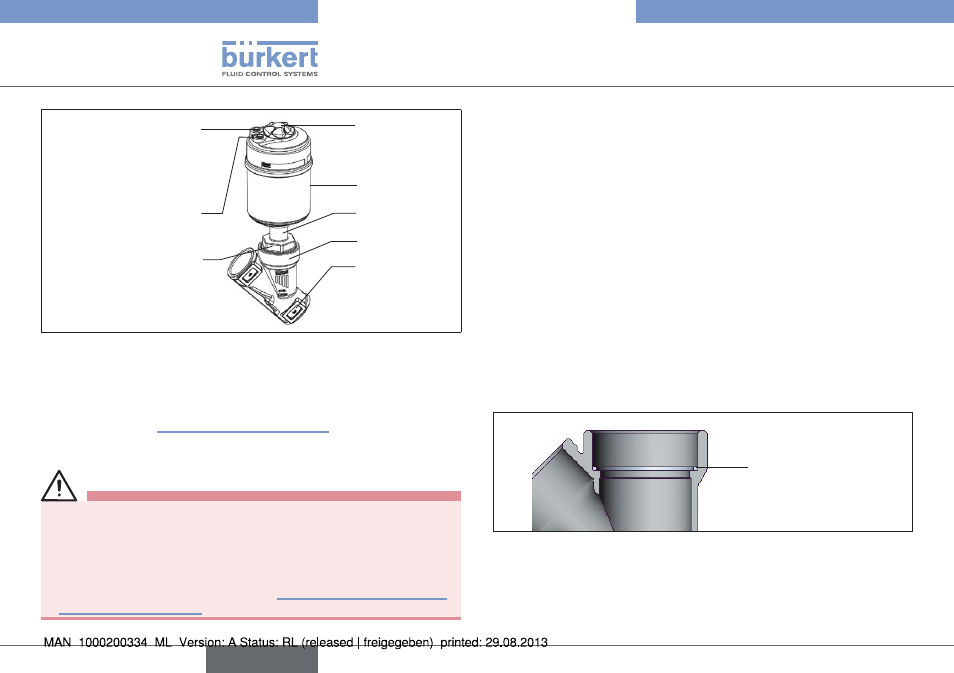

Actuator

Nipple

Valve body

Flats for open-end

wrench

Pilot air port

CFA, CFB, CFI

Air discharge connection

CFA, CFB

Pilot air port

CFI

2

1

Transparent cap

with position

indicator

Numbers for

indicating the

direction of

flow

Fig. 2:

Installation

Other device versions

→

Do not remove actuator unless this is a customer-specific

requirement.

→

Procedure see “Devices with welded body”.

7.3. Installation

WARNING!

Risk of injury from improper assembly!

Assembly with unsuitable tools or non-observance of the tight-

ening torque is dangerous as the device may be damaged.

• For installation use an open-end wrench, never a pipe wrench.

• Observe the tightening torque (see “Tab. 5: Tightening torques

Dirt trap for devices with authorization in accordance with DIN

EN 161

In accordance with DIN EN 161 „Automatic shut-off valves for gas

burners and gas appliances“ a dirt trap must be connected upstream

of the valve and prevent the insertion of a 1 mm plug gauge.

→

If the authorisation also applies to stainless steel bodies, the same

type of dirt trap must be attached in front of the angle seat valve.

7.3.1. Installation of the valve body

Welded bodies

→

Weld valve body in pipeline system.

Other body versions

→

Connect body to pipeline.

7.3.2. Install actuator (welded body)

Graphite seal

Fig. 3:

Graphite seal

→

Check the graphite seal and if required, replace it.

english

Type 2100