Xylem IM255 AQUAVAR Intelligent Pump Controller User Manual

Page 39

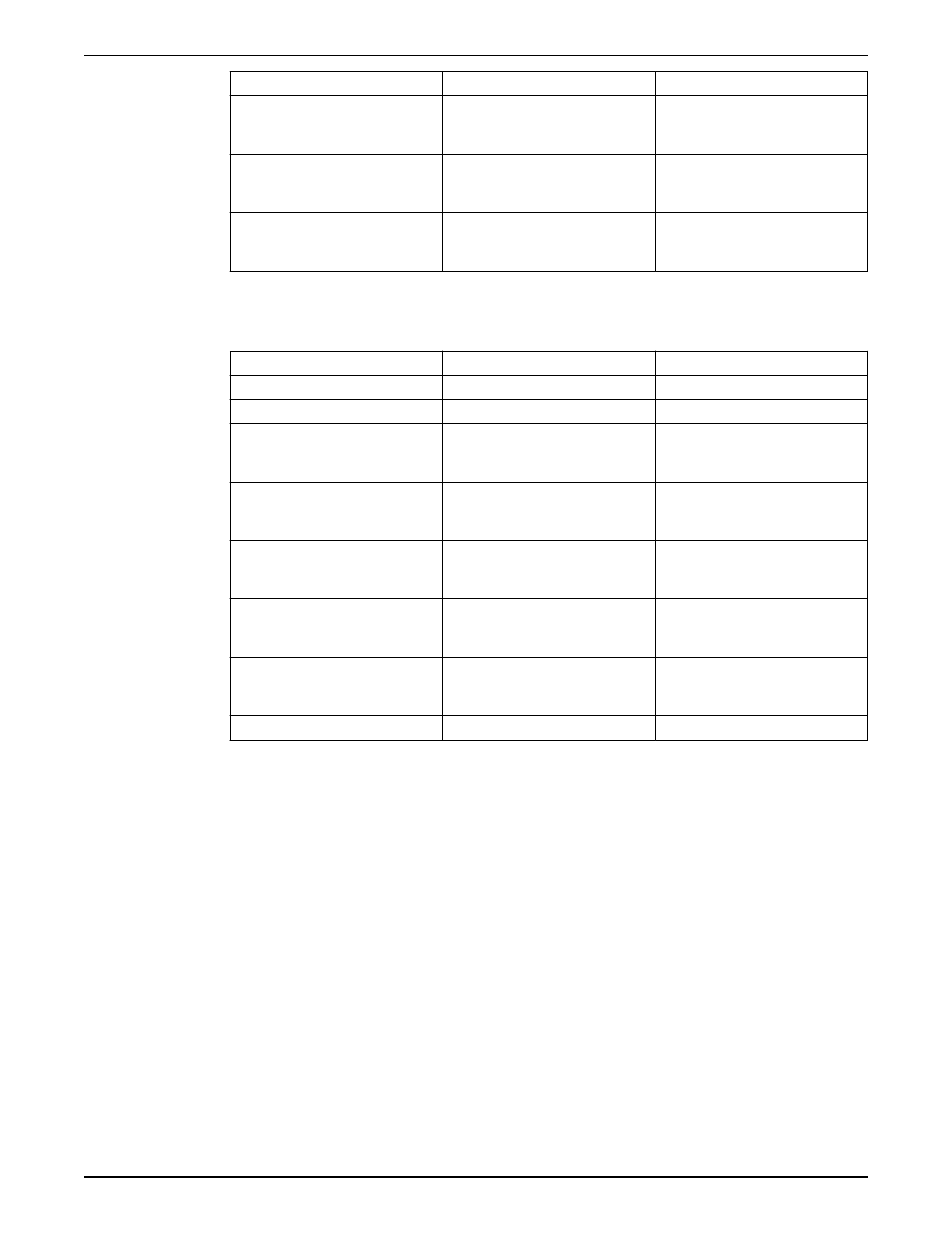

Parameter Number

Parameter Description

Set To

20-12

Reference/Feedback Unit

Select as appropriate for application.

For example, set to psi when using

pressure feedback.

20-13

Minimum Reference/Feedback

Minimum transducer feedback value.

For example, for a 0-300psi

transducer, set to 0.

20-14

Maximum Reference/Feedback

Maximum transducer feedback

value. For example, for a 300psi

transducer, set to 300.

* To use AI 53, configure parameters 6-14, 6-15, 6-17

Table 7: Parameters for an additional transducer used for monitoring

Parameter number

Description

Set to

0-24

Display Line 3 Large

Ext. 1 Feedback [Unit]

21-14

Ext. 1 Feedback Source

Analog Input 54*

21-10

Ext. 1 Ref./Feedback Unit

Select as appropriate for application.

For example, set to psi when using a

pressure transducer.

21-11

Ext. 1 Minimum Reference

Minimum transducer feedback value.

For example, for a 0-300psi

transducer, set to 0 psi.

21-12

Ext. 1 Maximum Reference

Maximum transducer feedback

value. For example, for a 300 psi DP

transducer, set to 300 psi.

6-24*

Terminal 54 Low Ref./Feedb. Value

Minimum transducer feedback value.

For example, for a 0-300 psi

transducer, set to 0.

6-25*

Terminal 54 High Ref./Feedb. Value

Maximum transducer feedback

value. For example, for a 300 psi

transducer, set to 300.

6-27*

Terminal 54 Sensor Fault

Disabled

* To use AI 53, configure parameters 6-14, 6-15, 6-17 and set 21-14 to Analog Input 53

Speed control through an analog input

The controller can be configured for speed control through an analog input. The

controlling source can be either an external control device such as a PLC, BMS (building

management system) or potentiometer. The output from the external control device can

be either a voltage or current output signal. Be sure to set the analog input configuration

Electrical Installation

Aquavar

®

Intelligent Pump Controller INSTRUCTION MANUAL

37