Xylem IM255 AQUAVAR Intelligent Pump Controller User Manual

Page 114

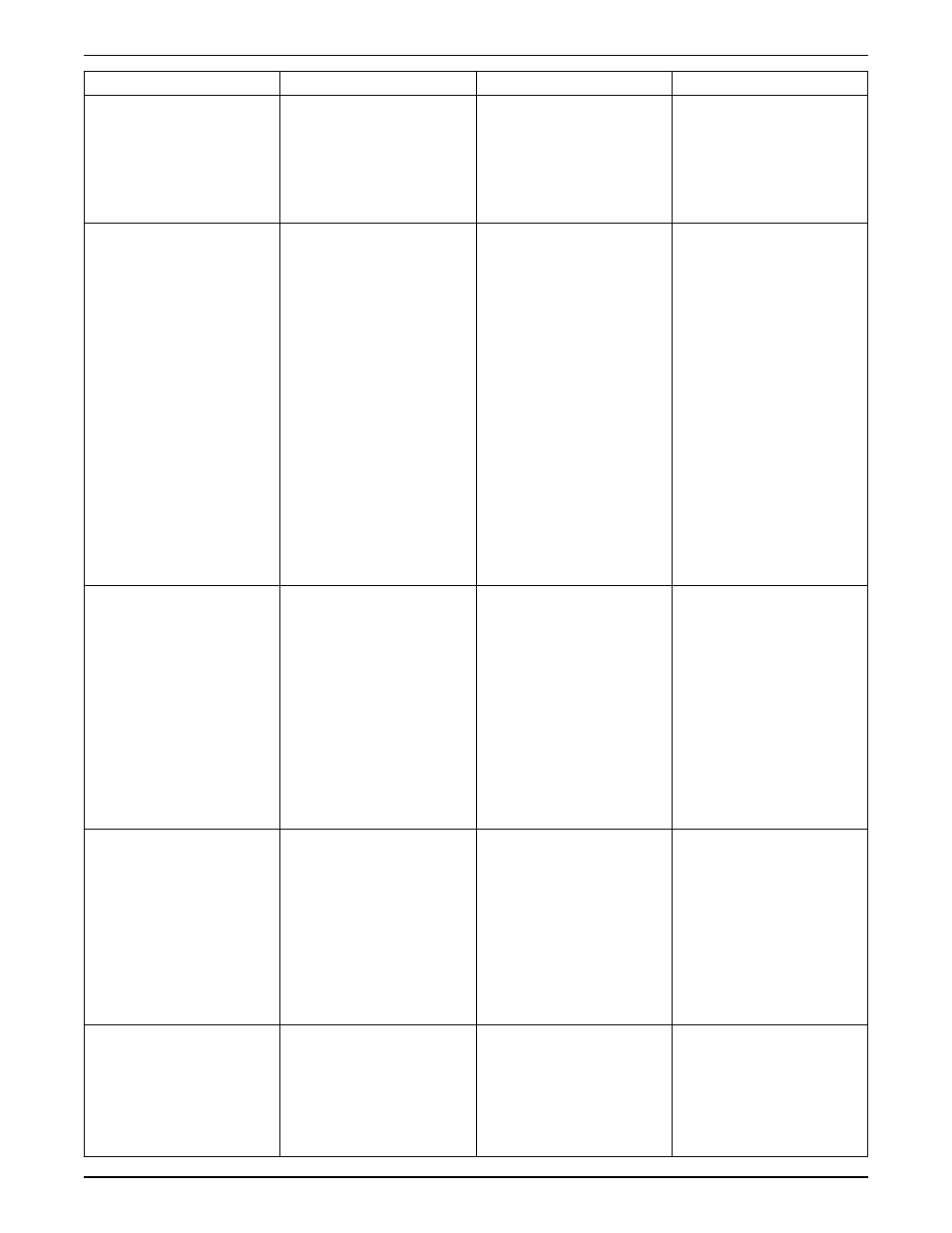

Warning/Alarm

Description

Cause

Remedy

10 — Motor overload temperature According to the electronic

thermal protection (ETR), the

motor is too hot. Select whether

the frequency converter gives a

warning or an alarm when the

counter reaches 100% in 1–90

Motor Thermal Protection.

The fault occurs when the motor is

overloaded by more than 100% for

too long.

Check for motor overheating.

Check if the motor is mechanically

overloaded.

Check that the motor current set in

[1–24] Motor Current is correct.

11 — Motor thermistor over temp The thermistor might be

disconnected. Select whether the

frequency converter gives a

warning or an alarm in 1–90

Motor Thermal Protection.

Check for motor overheating.

Check if the motor is mechanically

overloaded.

When using terminal 53 or 54,

check that the thermistor is

connected correctly between

either terminal 53 or 54 (analog

voltage input) and terminal 50

(+10 V supply) and that the

terminal switch for 53 or 54 is set

for voltage. Check [1–93]

Thermistor Source selects terminal

53 or 54.

When using digital inputs 18 or

19, check that the thermistor is

connected correctly between

either terminal 18 or 19 (digital

input PNP only) and terminal 50.

Check [1–93] Thermistor Source

selects terminal 18 or 19.

12 — Torque limit

The torque has exceeded the value

in 4–16 Torque Limit Motor Mode

or the value in 4–17 Torque Limit

Generator Mode. 14–25 Trip Delay

at Torque Limit can change this

from a warning only condition to a

warning followed by an alarm.

If the motor torque limit is

exceeded during ramp up, extend

the ramp up time.

If the generator torque limit is

exceeded during ramp down,

extend the ramp down time.

If torque limit occurs while

running, possibly increase the

torque limit. Be sure the system

can operate safely at a higher

torque.

Check the application for excessive

current draw on the motor.

13 — Over current

The inverter peak current limit

(approx. 200% of the rated

current) is exceeded. The warning

lasts about 1.5 seconds, then the

frequency converter trips and

issues an alarm. This fault may be

caused by shock loading or fast

acceleration with high inertia

loads. If extended mechanical

brake control is selected, trip can

be reset externally.

Remove power and check if the

motor can be turned.

Check that the motor size matches

the frequency converter.

Check parameters 1–20 through

1–25 for correct motor data.

14 — Ground/Earth fault

There is current from the output

phases to ground, either in the

cable between the frequency

converter and the motor or in the

motor itself.

Remove power to the frequency

converter and repair the earth

fault.

Check for ground faults in the

motor by measuring the resistance

to ground of the motor leads and

the motor megohmmeter.

Warnings and alarms

112

Aquavar

®

Intelligent Pump Controller INSTRUCTION MANUAL