GE Industrial Solutions GE ZENITH SERIES MDU User Manual

Page 34

GE

601

Plano, TX 75074

GE Z

ENITH

601 S

Plano, TX 75074

ENITH

S

HILOH

Plano, TX 75074

5.1.2.

5.1.3.

ENITH

C

ONTROLS

HILOH

R

OAD

Plano, TX 75074

5.1.2.

5.1.3.

ONTROLS

OAD

Plano, TX 75074

5.1.2.

5.1.3.

ONTROLS

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

core solution for

ea

Current Transformers (CT’s)

When attaching solid

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

core solution for

each have two wires for existing p

Current Transformers (CT’s)

When attaching solid

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

core solution for

ch have two wires for existing p

Current Transformers (CT’s)

When attaching solid

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

core solution for

ch have two wires for existing p

Current Transformers (CT’s)

When attaching solid

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

core solution for

ch have two wires for existing p

Current Transformers (CT’s)

When attaching solid

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

core solution for new installation applications and individually mounted split core CT’s that

ch have two wires for existing p

Current Transformers (CT’s)

When attaching solid

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

ch have two wires for existing p

Current Transformers (CT’s)

When attaching solid-core CTs for sub

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

MDU Owner’

Current Transformers (

The current transformers are

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

ch have two wires for existing p

Current Transformers (CT’s)

core CTs for sub

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

MDU Owner’

Current Transformers (Panel

The current transformers are normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

ch have two wires for existing p

Current Transformers (CT’s)

core CTs for sub

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

MDU Owner’

Panel

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

ch have two wires for existing p

Current Transformers (CT’s)

core CTs for sub

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

MDU Owner’

Panel board

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

ch have two wires for existing panel

Current Transformers (CT’s)

core CTs for sub

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

MDU Owner’s Manual

board

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

anel board applications are available.

core CTs for sub-feed monitoring

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

s Manual

board

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

feed monitoring

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

s Manual

board CT’s)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

feed monitoring

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

Bran

s Manual

CT’s)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

feed monitoring

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

Bran

CT’s)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

feed monitoring

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

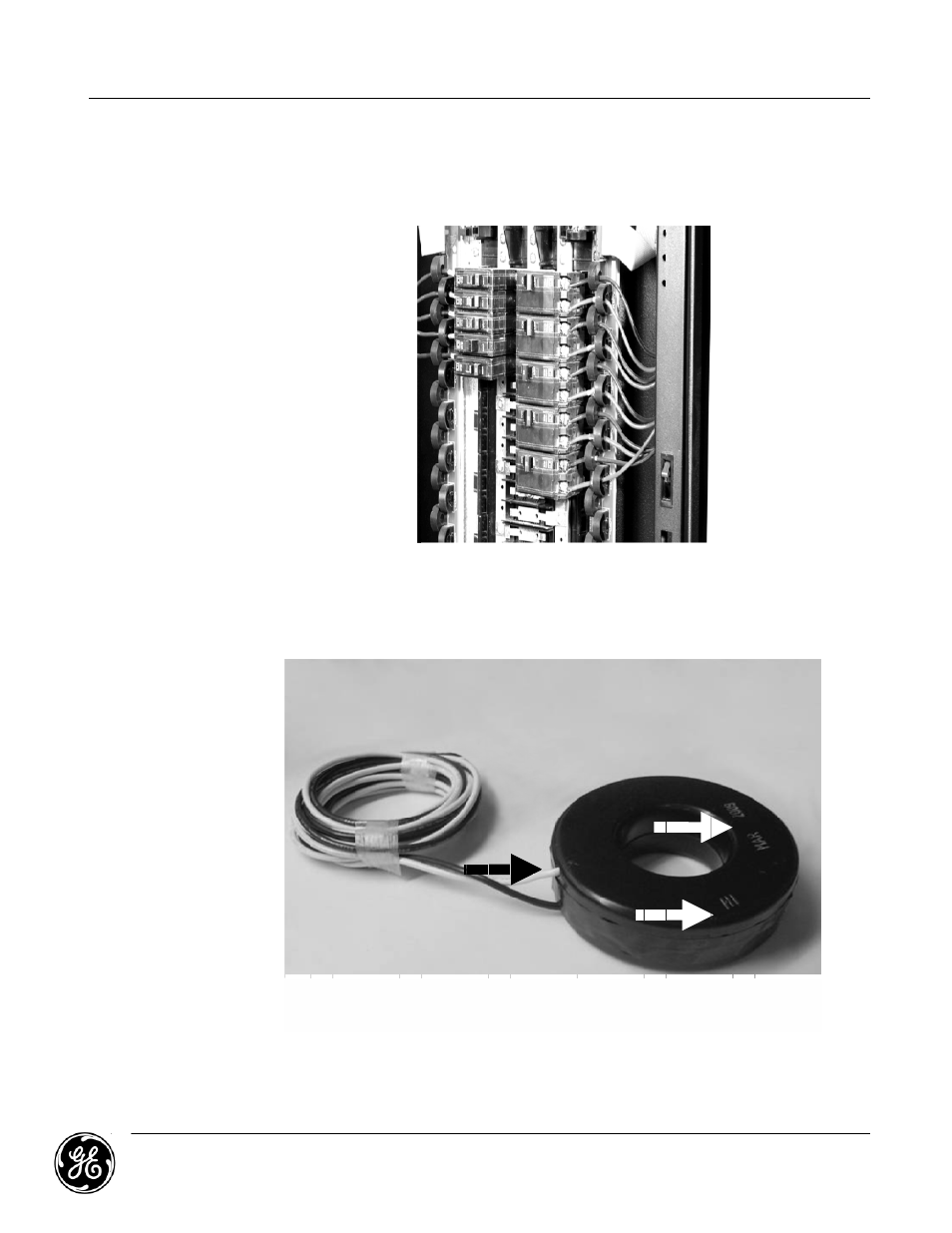

Branch Circuit Monitoring System (BCMS)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

feed monitoring purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

identified from the imprinted “H” and Manufacture date.

ch Circuit Monitoring System (BCMS)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

board applications are available.

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

January 2013

Page

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

January 2013

Page

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

January 2013

Page 34

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

connected to the breaker. These are mounted to a printed circuit board with the solid

new installation applications and individually mounted split core CT’s that

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

January 2013

34

normally placed on both sides of a panel board. The wire to

each branch breaker is then run through the appropriate current transformer before being

new installation applications and individually mounted split core CT’s that

purposes make sure the label and

white wire should face the load. Always remember “label faces load”. The label can be

ch Circuit Monitoring System (BCMS)

each branch breaker is then run through the appropriate current transformer before being