Torque specifications, Torque value quick reference, Structural fasteners – GE Industrial Solutions GE ZENITH SERIES MDU User Manual

Page 14: Standard circuit breakers (mains & sub-feeds)

Installation Procedures

GE Z

ENITH

C

ONTROLS

MDU Owner’s Manual

601 S

HILOH

R

OAD

January 2013

Plano, TX 75074

Page 14

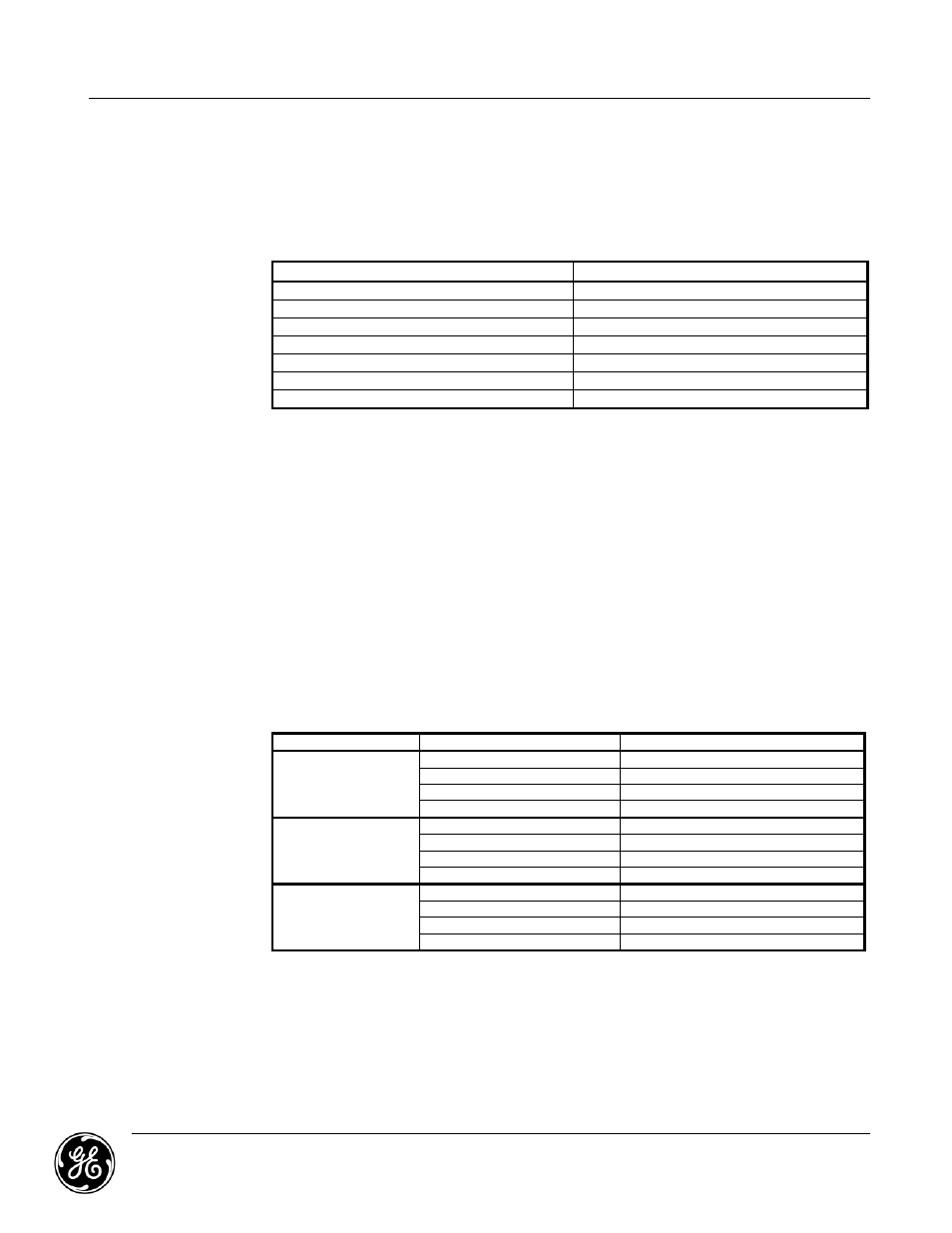

3.6.

Torque Specifications

3.6.1. Structural Fasteners

Structural fasteners are typically used for fastening the MDU to a supplied floor stand or

concrete slab. If structural fasteners are required per assembly instructions, refer to the

table below for typical torque values. Tighten steel hardware parts (except electrical

connections) to the values given in the following table.

Bolt Diameter

Tightening Torque (in-lb)

#8 (5/32”)

15

#10 (3/16”)

20

1/4”

120

5/16”

228

3/8”

396

7/16”

648

1/2”

936

3.6.2. MCCB’s, MCSW’s, Contactors, and Other Electrical Components

Always tighten electrical component (CBs, contactors, etc.) connections to the

manufacturer’s torque specifications furnished with the component. There are some

guidelines for electrical components if no manufacturer data is available. Tighten

connections using Belleville type (spring) washers until washers are flat.

3.7.

Torque Value Quick Reference

Use the following as a reference only. Always check the breaker or component labeling and/or

instructions for proper torque values. DO NOT OVER TORQUE!

Always use the manufacturer’s hardware on CBs, contactors, etc. Once connections are torqued and

sealed, make sure that removable lug covers are reinstalled,

3.7.1. Standard Circuit Breakers (Mains & Sub-feeds)

Manufacturer

Breaker Frame / Bolt

Required Torque (ft-lb)

Square D

F Frame

6.7

K Frame

20.9

L Frame

31.3

M Frame

25.0

Cutler Hammer

F Frame

10.0

J Frame

22.9

K Frame

22.9 (Wire Smaller than 250 MCM)

K Frame

31.3 (Wire 250 MCM or larger)

ABB ISOMAX

Rear Lug Mounting Bolt

requires

S3

22.9

S4

22.9

S5

22.9

Rear Lug Mounting Bolt

9.2