Installation instructions, Series np-le airflo, Burners – Grain Systems PNEG-526 User Manual

Page 97: Corporation, Industrial combustion equipment and valves, General, Supports

m

CORPORATION

MUNCIE, INDIANA, USA

INDUSTRIAL COMBUSTION EQUIPMENT AND VALVES

Maxon practices a policy of continuous product improvement. It reserves the right to alter specifications without prior notice.

Series NP-LE AIRFLO

®

Burners

Installation Instructions

General

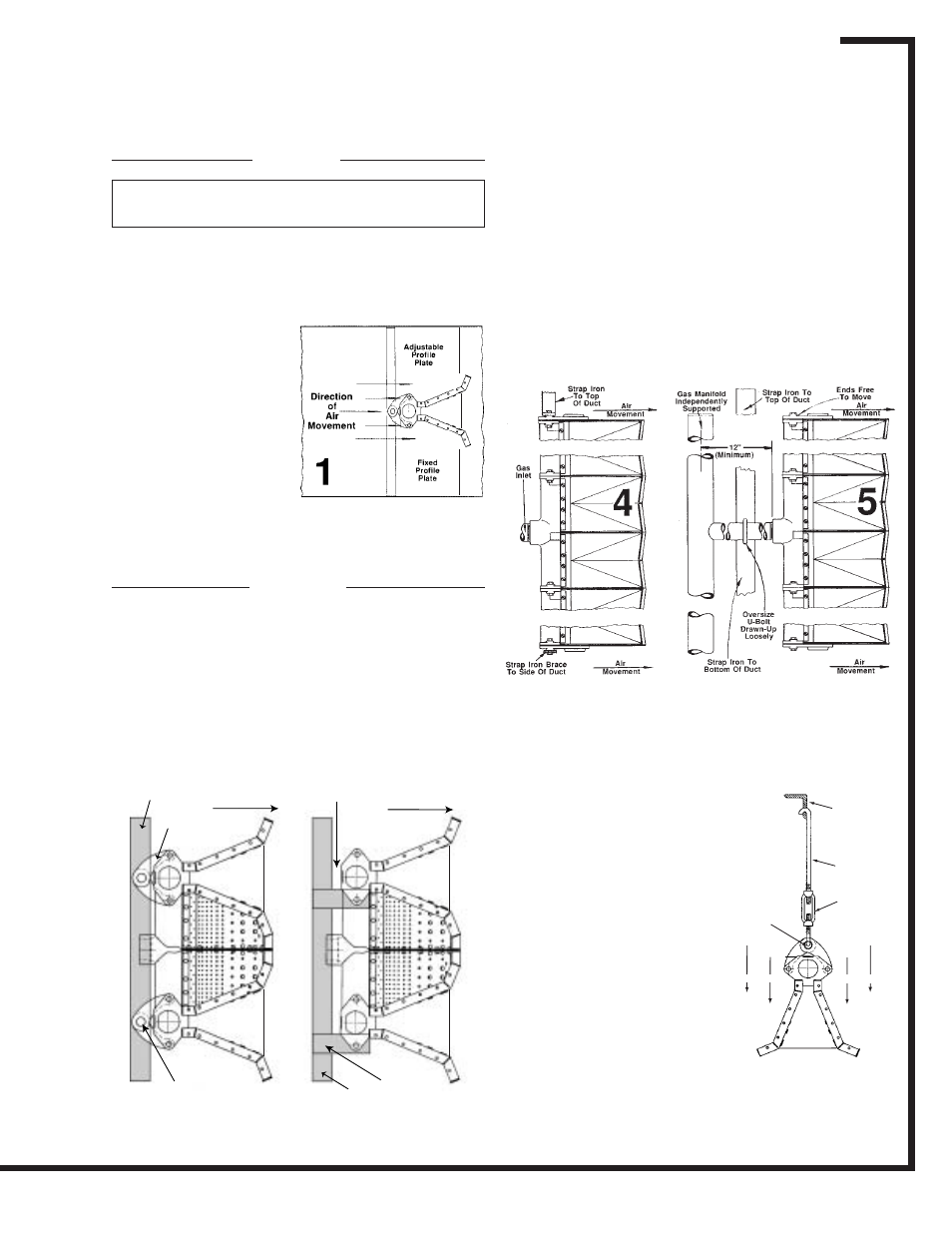

Avoid bending or damaging the steel mixing plates

of your Series NP-LE AIRFLO

®

Burner during

uncrating and installation.

These burners are used

for the heating of fresh air

in motion. Mount the

burners so they fire parallel

to and in the same direc-

tion as the movement of

the air (see sketch 1 at

right).

Velocity and flow of air

at operating temperature

must be uniform. Minimum

silhouette profile plates of

6" should be installed in

Important: Do not discard packing material until

all loose items are accounted for.

duct to completely surround burner assembly.

Supports

Series NP-LE AIRFLO

®

Burner assemblies must be

adequately supported and positioned.

Avoid rigid mounting. Burner assembly expands

and contracts with temperature variations.

Maintain smooth, even air flow over the burner by

designing supports to provide minimum interference,

deflection and turbulence.

The sketches below show typical installation and

support methods:

Sketch 2 shows the burner suspended from a strap

iron frame using Maxon USB support brackets. Note

that rigid mounting is avoided by the bracket hole

which slips loosely over a bolt or steel rod attached to

the support. Gas piping would need independent

support.

Sketch 3 shows the burner assembly resting upon

angle iron brackets and not attached to them in any

way. Be sure the angle iron supports allow the burner

flanges to expand and contract. Gas manifolding

would be independently supported and prevent

forward movement of the burner.

the burner. If there are

multiple inlets, you must

avoid rigid connection by

using the oversize U-bolt

(loosely drawn up) illustrated.

Support for down-fired

burners can be accomplished

as shown in the illustration at

right. Always avoid rigid

mounting.

Sketch 6 shows Maxon

USB support brackets

suspending the burner from

an overhead angle iron.

Sketch 7 shows an alter-

nate arrangement which

offers the advantage of more

controlled positioning.

6/03

Sketch 4 shows simple strap iron used to support

the burner. Note that narrow edge of strap faces air

flow to avoid undue turbulence.

Sketch 5 shows gas manifolding used to support

Page 5550-S-1

Strap Iron

Frame

Maxon

Support

Brackets

Allow Space

for Burner

Expansion

Air

Movement

Air

Movement

Bolt or Rod

Long enough to permit

brackets to move with

burner expansion

Angle Iron

Support

Strap Iron

Frame

2

3

6

Angle

Iron

Support

Rod

Support

Brackets

3/4"

Hole

Air

Movement

Air

Movement