Grain Systems PNEG-526 User Manual

Page 152

e

-

.

,

w

A-1

2

i

I

I

I

Note:

number

slow speed

number

side.

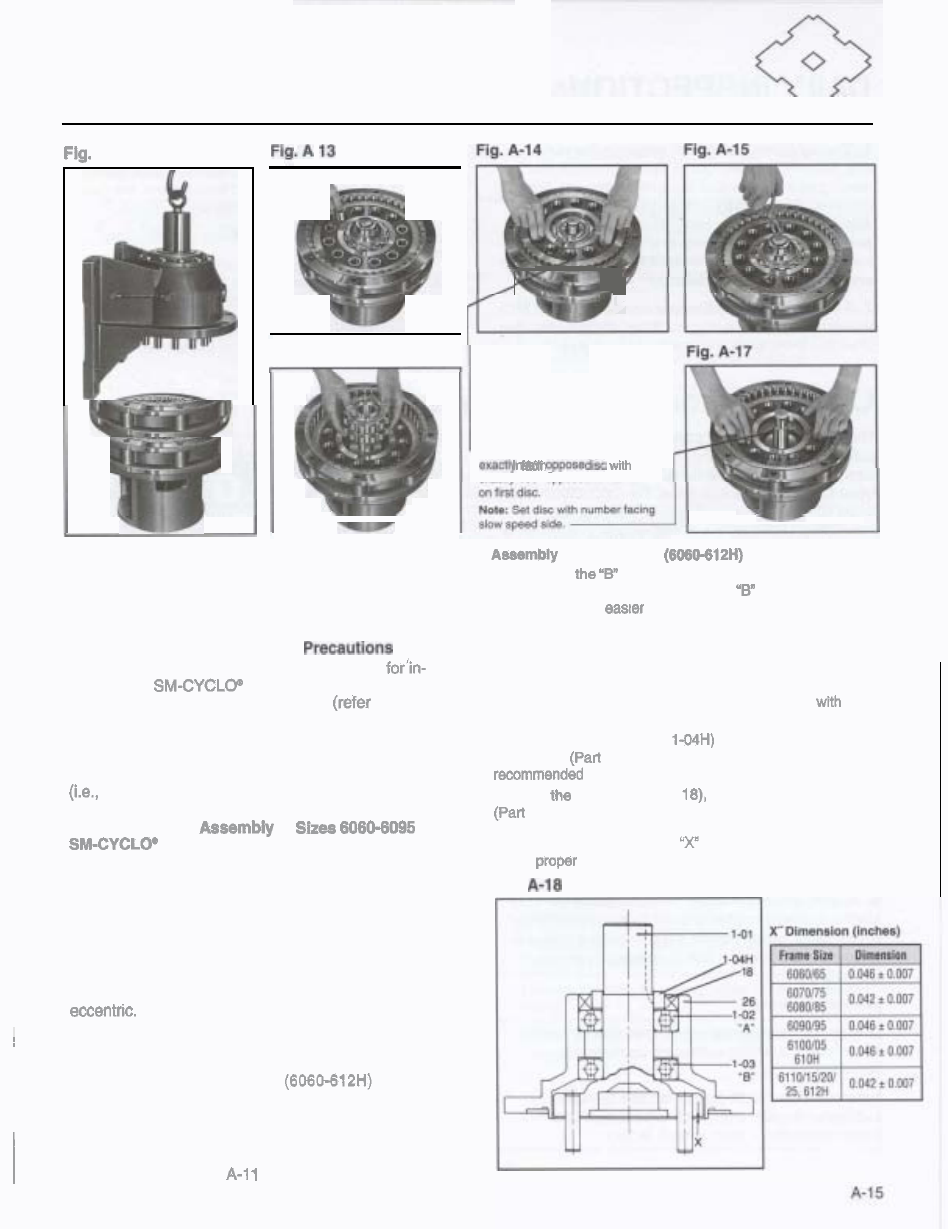

b. Apply grease to the raceway of the eccentric on the

Of Output

Slde

disc. Fix the rollers and set disc in place.

1.

Assemble

bearing (Part No.

1-03)

on the slow

c. Insert the spacer ring and set second disc in such a

speed shaft (Part No.

1-01).

Heating

of

bearing is

way that mark is 180' opposed to mark on the bottom

recommended for

assembly.

disc.

Note.

Do

not exceed temperature

of

200°F.

Eccentric Bearing Replacement

2.

Assemble Me casing (Part No.

26)

over the slow speed

The eccentric bearings are specially designed

shaft (Part No.

1-01),

being sure to maintain

"X"

(Fig.

A-18).

stallation on

Reducers. They are special

3.

Carefully tap bearing

'A"

(Part No.

1-02)

onto the slow

roller bearings without outer raceways

to the list

speed shaft (Part No.

1-01)

until the bearing is flush

the

of bearings on pages A-12

-

A-13).

shoulder of the casing.

It is necessary to insert replacement bearings with

4.

Place the collar (Part No.

onto the slow

numbered surfaces of the inner raceways facing

speed shaft

No.

1-01).

Heating Me collar is

outward. Note that incorrect insertion of the bearings

for easier assembly.

insertion of bearings with numbered surfaces

5.

Insert

oil seal (Part No.

lip in, into the casing

inside) causes trouble.

No.

26).

Disassembly

and

of

Reducers

Note:

Measure for dimension

preferably in

3

places

to

Small sizes 6060-6095 have a single disc system, so

insure

spacing.

they differ in construction from larger sizes in the

Fig.

following ways:

1.

A

balance weight is provided in lieu

of

the two-disc

system. Refer to figure A-18.

2. The balance weight must be positioned exactly 180"

as opposed to that of the eccentric.

i

3. There are no end plates on either side of the

In all other respects,

6060-6095 have

exactly the same construction as the larger sizes.

Follow the instructions given under "Disassembly and

Assembly".

Disassembly Of Output Side

1.

With casing supported, tap output shaft until it is

disengaged from casing.

2. Remove bearing "A" by using pulling tool.

3. Replace all bearings, gaskets and seals when

reassembling. (Pages

-

A-13).

.

,

Flg.

A-16