Maintenance instructions, Corporation, Industrial combustion equipment and valves – Grain Systems PNEG-526 User Manual

Page 127

m

CORPORATION

MUNCIE, INDIANA, USA

INDUSTRIAL COMBUSTION EQUIPMENT AND VALVES

Maxon practices a policy of continuous product improvement. It reserves the right to alter specifications without prior notice.

Manual

Valve

A

Manual

Valve

B

Shut-off

Valve

#1

Vent

Valve

Drip

Leg

Strainer

Shut-off Valve #2

Gas Pressure

Regulator

To Combustion

System

LGP

Switch

HGP

Switch

Maintenance Instructions

Page 6100-S-13

Electro-Mechanical Valves

2/00

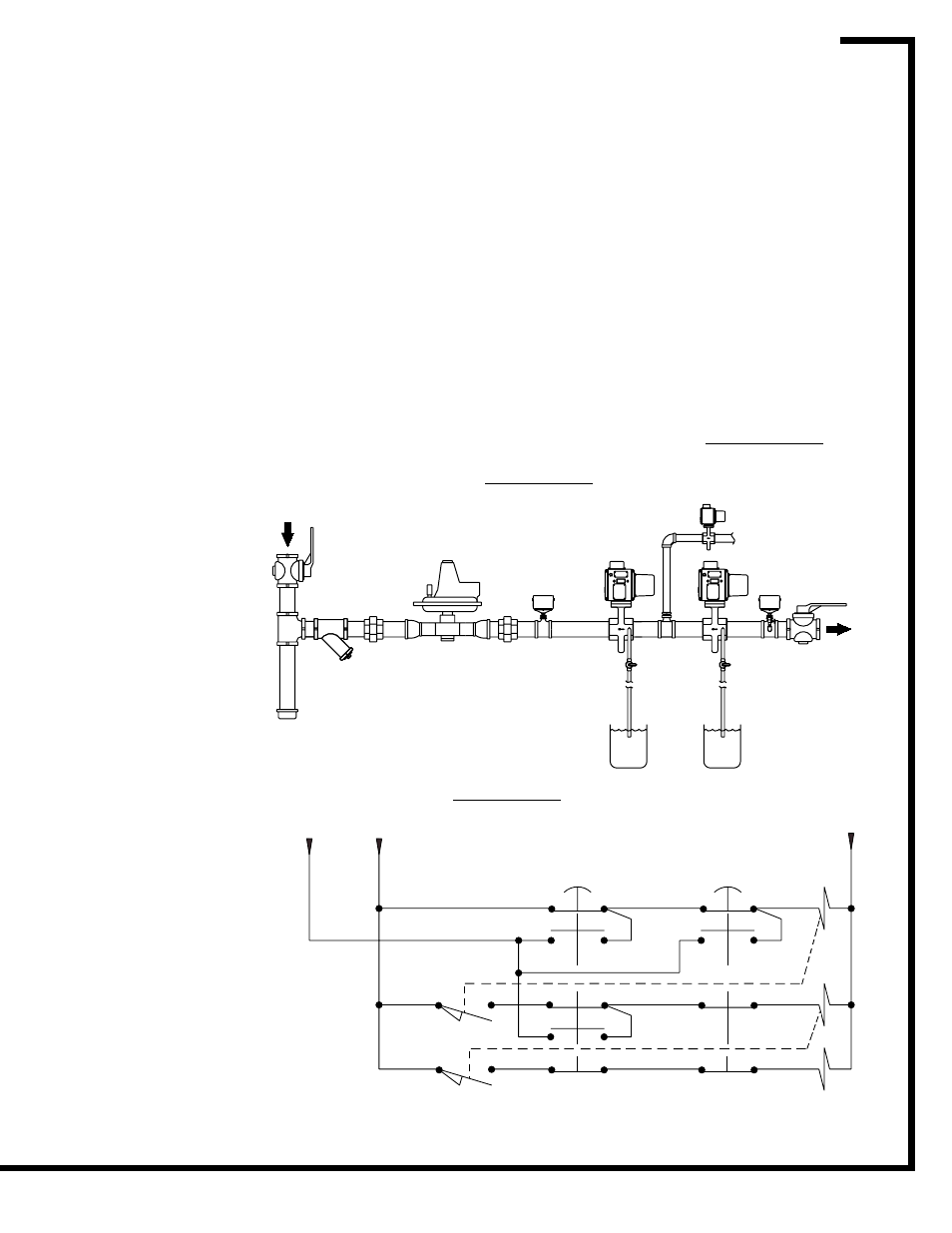

Suggested leak test procedure for double-blocking shut-off valves with vent line

Example of a gas piping diagram for leak test with vent line

Example of a wiring diagram for leak test with vent line

(h) Secure test apparatus on valve #1.

(i) Remove the 1/4” pipe plug from downstream side

of shut-off valve #2. Install leak test apparatus.

(j) With an auxiliary power supply connected to valve

#1, open test apparatus and test valve for leak-

age. As a guideline, valve should be tested for 2

minutes per inch of pipe diameter. Large diameter

pipes or long piping runs between shut-off valves

may need additional testing time.

(k) If valve testing indicates leakage exceeding 15

bubbles per minute, perform pre-operational

exercising as outlined on Page 6100-S-2 and

retest the valve. If valve continues to exceed

allowable leakage limit, remove from service and

contact Maxon.

(l) Secure test apparatus on valve #2.

(m) Upon completion of valve leak testing, test all

other safety interlocks per manufacturer’s instruc-

tions and verify they are operational.

(n) Restore combustion system to operational

condition. Be sure to remove all auxiliary power

supplies and jumpers that may have been used

during testing.

Suggested leak test procedure for double-blocking shut-off valves (without vent line) - continued

If vent valve is

present, use auxil-

iary power supply to

power vent valve to

closed position

during this test

procedure. Follow

test instructions

above. Once test is

complete, be sure

vent valve is re-

stored to normal

operation.

Hot

LS-VV

LS-SV

From Flame

Safeguard

Shut-off Valve #2

Momentary Leak

Test Push Button

Shut-off Valve #1

Momentary Leak

Test Push Button

Shut-off

Valve #2

Shut-off

Valve #1

Vent

Valve

Neutral

NOTES:

Push button must be tamper

resistant.

LS-VV – Closes when Vent

Valve is fully closed

LS-SV – Closes when Shut-

off Valve #1 is fully open.

The “From Flame Safe-

guard” line is energized only

when sall conditions for

safe operation have been

satisfied.